Next week NFM will launch two new 4th generation combat helmets at Milipol and look forward to introducing the HJELM™ HC 120MT and the HJELM™ HC 160F.

Ski, Norway, November 10th 2023: These two new combat helmets are engineered to deliver unparalleled protection, comfort, and performance for military and law enforcement personnel.

“Our focus at NFM has always been on the end-user – the men and women in uniform who require the best protection available. With the HJELM™ HC 120MT and HC 160F, we have taken a significant leap forward in delivering helmets that not only protect our end-users but also enhance their operational capabilities,” said Tor Inge Thun, Chief Product Integration Officer at NFM Group.

“Every gram count when it comes to the gear our soldiers and officers carry,” says Thun.

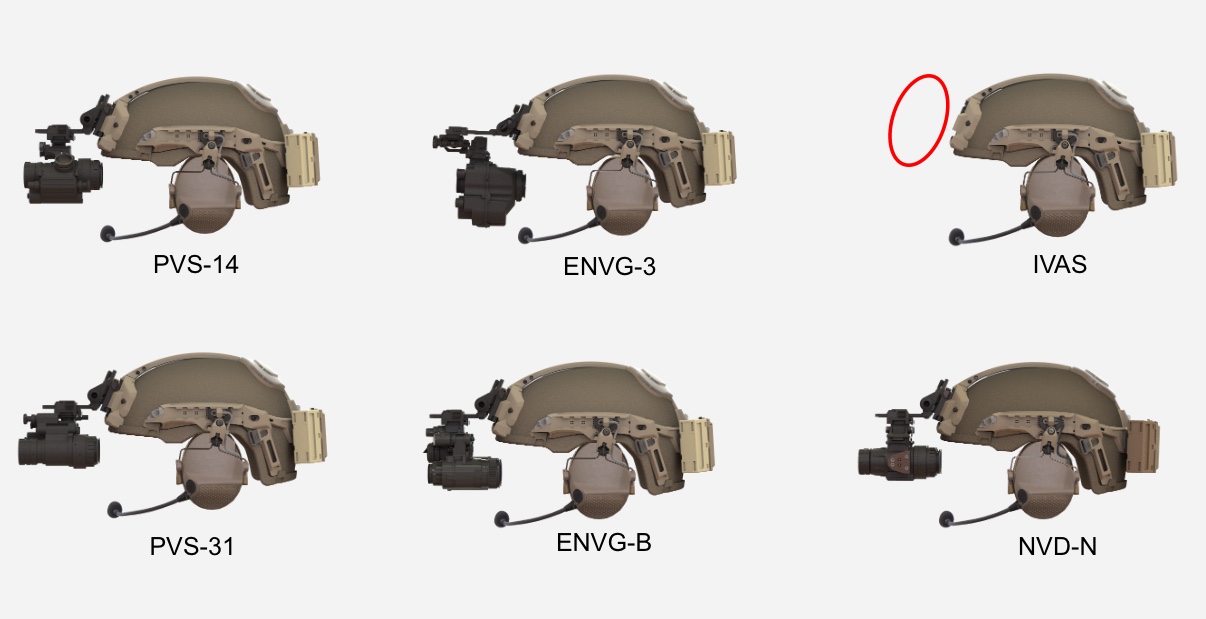

The HJELM™ line represents the next generation of combat helmets, integrating advanced information technology and leading-edge protection against the threats on the modern battlefield.

“With our unique FREC-2™ Technology we have developed the best Weight-Performance-Ratio combat helmet with functional design available. HJELM™ Combat Helmets comes in six different sizes and provides superior comfort, load distribution and stabilization”, says Mike Langenohl, Director of Head Systems at NFM.

The new editions to NFM HJELM™ Combat Helmet System line features:

HJELM™ HC 120MT (Multi-Threat) is designed to address an extensive range of threats while emphasizing a lightweight profile for operational agility.

HJELM™ HC 160F (Fragment) has been developed to meet the most demanding weight saving requirements while providing a high level of fragment protection.

Optimal Weight-Performance Ratio: NFM HJELM combat helmets have the best weight-performance ratio in the market, ensuring that protection does not come at the expense of mobility or comfort.

FREC-2™ Pressing Technology: Utilizing our patented FREC-2™ pressing technology, these helmets offer advanced structural integrity while maintaining a lightweight profile.

Revolutionary Sizing System: A unique sizing system guarantees a precise fit for a wide range of head shapes and sizes, providing maximum comfort and stability.

Innovative Interior Design Concept: Our new interior design concept includes the Skullplate Liner and various chinstrap options, allowing for a customizable fit and enhanced shock absorption.

Advanced Impact Management by KOROYD: Incorporating KOROYD technology, the helmets deliver superior impact management, safeguarding the wearer against a spectrum of impact forces.

Each feature is a demonstration to our commitment to innovation and excellence in providing the best protective equipment to those who serve.

“The HJELM™ HC 120MT and HC 160F helmets are a testament to our design philosophy, where added weight is only justified by increased functionality. We are proud to set a new standard in the industry,” says Tor Inge Thun, Chief Product Integration Officer at NFM Group.

NFM will be demonstrating the capabilities of the HJELM™ HC 120MT and HJELM™ HC 160F Combat Helmets on Milipol Paris 2023, booth 5D 083 between November 14th and 17th.

For more information about NFM Group and our industry-leading products, please visit www.nfm.no