NATICK, MASSACHUSETTS, UNITED STATES

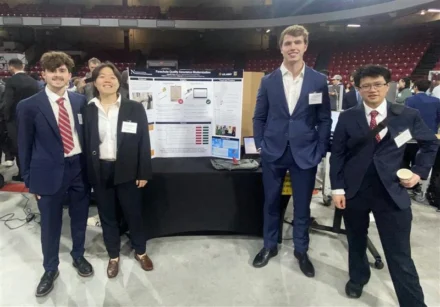

NATICK, Mass. – In a strategic collaboration with the Army’s Personnel Airdrop Systems (PADS) team, a group of Northeastern University industrial engineering students culminated their senior capstone competition, delivering more than first prize.

The Parachute Quality Assurance Modernization Team, mentored by U.S. Army Combat Capabilities Development Command (DEVCOM) aerospace engineer Tashfiq “Tash,” Salam, stood out among 40 engineering teams, each challenged to develop real-world solutions for government and industry use.

Guided by a shared mission, the team of four delivered an award-winning design: a suite of integrated digital tools, modernizing quality assurance for one of Airborne’s most critical and lifesaving capabilities – the personnel parachute systems.

Under the Assistant Secretary of the Army for Acquisition, Logistics, and Technology ASA(ALT) acquisition standards, every newly manufactured parachute must undergo a thorough inspection before being fielding to units. For the PADS team, this typically requires inspecting 8 to 13 parachutes at a time. According to the students’ research, that process can involve manually reviewing more than 5,000 data points, inspecting and measuring every stitch of fabric, harness and compartment encompassing a parachute system.

“It’s physically demanding,” Tash said. “You’re handling this large parachute; you have to inspect every inch of it. There’s a lot of surface area and a lot of steps.”

Over the course of the capstone project, the team studied those protocols applying direct feedback from quality assurance specialists, engineers and industry professionals. Their final prototype introduced an integrated software system complete with a set of digital measuring tools, capable of logging exact measurements up to 1/16th of an inch with a single click.

Tash shared how the students’ concept significantly improved the QA process, demonstrating the ability to reduce manual inspection time by nearly two hours without compromising quality.

“This is a zero-tolerance environment,” Salam said. “And the operating environment continues to get more complex every day. We needed to ensure the parachute capability we deliver is 100 percent what Soldiers need and in the way they want it. Because at the end of the day, once they land, they still have a follow-on mission. The parachute is just a ride to the mission.”

To support their research, students conducted site visits at the U.S. Army Natick Soldier Systems Center in Massachusetts, where Tash serves as a government civilian with Product Manager – Soldier Clothing and Individual Equipment (PdM SCIE), under the Program Executive Office – Soldier. They also met with DEVCOM engineers and Rhode Island National Guard members to gather feedback from quality assurance specialists and Soldiers who regularly perform parachute inspections

With more than 200,000 military free-fall and static line jumps conducted annually, ensuring consistent quality in each parachute is critical to Soldier safety.

“They understood the weight of that responsibility,” said Tash. This wasn’t about checking a box on an academic checklist; they were creating a real capability.”

The centralized system also enhances traceability, allowing inspectors to better assess the acquired measurements and key data points through the digital took it. The data is reported with real time feedback giving the PADS QA team the ability to run analytics on past inspections, identify error trends and performance metrics. As described by Tash, the system supports the PADS team mission of continuously delivering world class products to the airborne warfighter.

Ensuring students were immersed in PADS and SCIE operations was faculty advisor and key partner Dr. B. Kris’ Jaeger-Helton, Director of Capstone Design for Industrial Engineering at Northeastern. Jaeger-Helton celebrated the project as an important model for real-world learning.

“The experience was both challenging and open-ended, with clearly defined security constraints that had to be followed as well, making it the ideal Capstone project,” she said.

This year’s team built upon the foundation of the 2023–2024 capstone, which transitioned the Army’s inspection records from paper-based logs to an Excel-based digital tool. With Tash’s mentorship, this year’s Capstone expanded that concept collecting data from the T-11, MC-6, and RA-1 parachute systems.

Jaeger-Helton, who supported both capstone efforts, emphasized the value of the Army–academic collaboration.

“The capstone students genuinely benefitted from the support of Tash’s dedicated and highly knowledgeable team,” she said. “As clients, the Army PADS team communicated the importance, seriousness, and value of this initiative, while also expressing their trust and confidence in the Northeastern team. I’m looking forward to continuing our partnership for more great initiatives.”

Now in his second year mentoring a NU engineering capstone, Tash highlighted the importance of engaging with emerging talent in support of innovation and advancing Army capabilities.

“That kind of ingenuity and creativity has to come from somewhere, and it often comes from a sense of purpose in what you’re working on,” Salam said. “There was a lot of pride in the student team because they knew they were doing something that matters.”

Story by Khylee Woodford

PEO Soldier