To meet the demand for special operations warfighters and improve retention rates for these critical career fields, United States Air Force officials activated the Special Warfare Training Wing Oct. 10, here.

The mission of the new wing is to select, train, equip, and mentor Airmen to conduct global combat operations in contested, denied, operationally limited, and permissive environments under any environmental conditions.

“This new wing will help us provide additional oversight and advocacy for the complex, high-risk and demanding training that’s necessary to produce Airmen to meet the requirements of the joint force,” said Col. James Hughes, SWTW commander.

The new wing headquarters and subordinate organizational structure will consist of approximately 135 personnel. The existing Battlefield Airman Training Group, which was activated in June 2016, has been renamed to the Special Warfare Training Group and will report to the SWTW.

Building upon what the Battlefield Airmen Training Group has started, the previously established five pillars of marketing and recruiting, manpower and leadership, curriculum, equipment and infrastructure will serve as a starting point for the wing.

“Keeping these pillars in mind will allow us to continue focusing on building the best Airman we can from the time they step into a recruiter’s office up until the end of their careers,” said Hughes.

“Wings move the ball forward at an operational and strategic level,” said Hughes. “They can provide structure, oversight, strategic vision and unity of command. But to become a leader in the special warfare community, we have to continue pushing the envelope of science and technology. It all comes down to doing everything we can to create Airmen capable of problem solving across a wide-range of national security challenges to meet the joint force’s needs.”

Additionally, the wing will focus on improving human performance by staying at the forefront of science and technology with the addition of the Human Performance Support Group, a one of kind unit that will integrate specialists from a variety of sports and medical fields into special warfare training to optimize physical and mental performance, reduce injury and speed rehabilitation to create more capable and resilient ground operators.

“By pushing the limits of science and technology, we’re going to find the most efficient and effective methods for improving human performance,” said Hughes. “We’re going to take what we already have learned and enhance how we produce the most physically and psychologically fit Airmen possible for the joint force.”

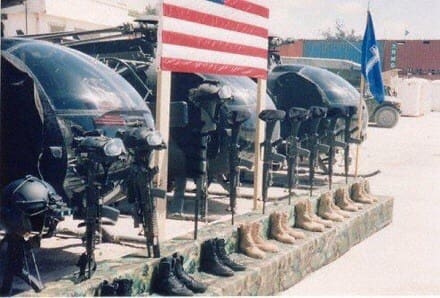

Special Warfare Airmen, previously known as Battlefield Airmen, are the critical ground link between air assets and ground forces. They are trained to operate as a ground component to solve ground problems with air power, often embedding with conventional and special operations forces. Their requirements have grown substantially since 2001 due to the effectiveness of and increasing demand for the precision application of air power in the joint combat environment.

Seven Air Force specialty codes currently fall into the Special Warfare category: Pararescue, Combat Rescue Officer, Combat Control, Special Tactics Officer, Special Operations Weather Team, Tactical Air Control Party personnel, and non-rated Air Liaison Officer. These Airmen share ground combat skill sets and a sharp focus on joint, cross-domain operations.

The first step toward more efficient and effective training is to combine the courses of initial entry for all special warfare candidates into one cohesive course.

“The various Special Warfare Air Force specialty codes are a lot more similar than they are different,” said Chief Master Sgt. James Clark, SWTW command chief. “These courses of initial entry are the bedrock of lethality and readiness. By combining them, we’re making the pipeline much more efficient, while also building a team mentality that focuses on our similarities, rather than our differences.”

This change is also the first step toward answering the most important question facing the SWTW: How do we create and develop the most adaptive and agile leaders possible?” said Clark. “It starts by continuing to be critical of ourselves, while searching for any way to become more efficient in everything that we do.”

www.specialwarfaretw.af.mil

-Air Education and Training Command