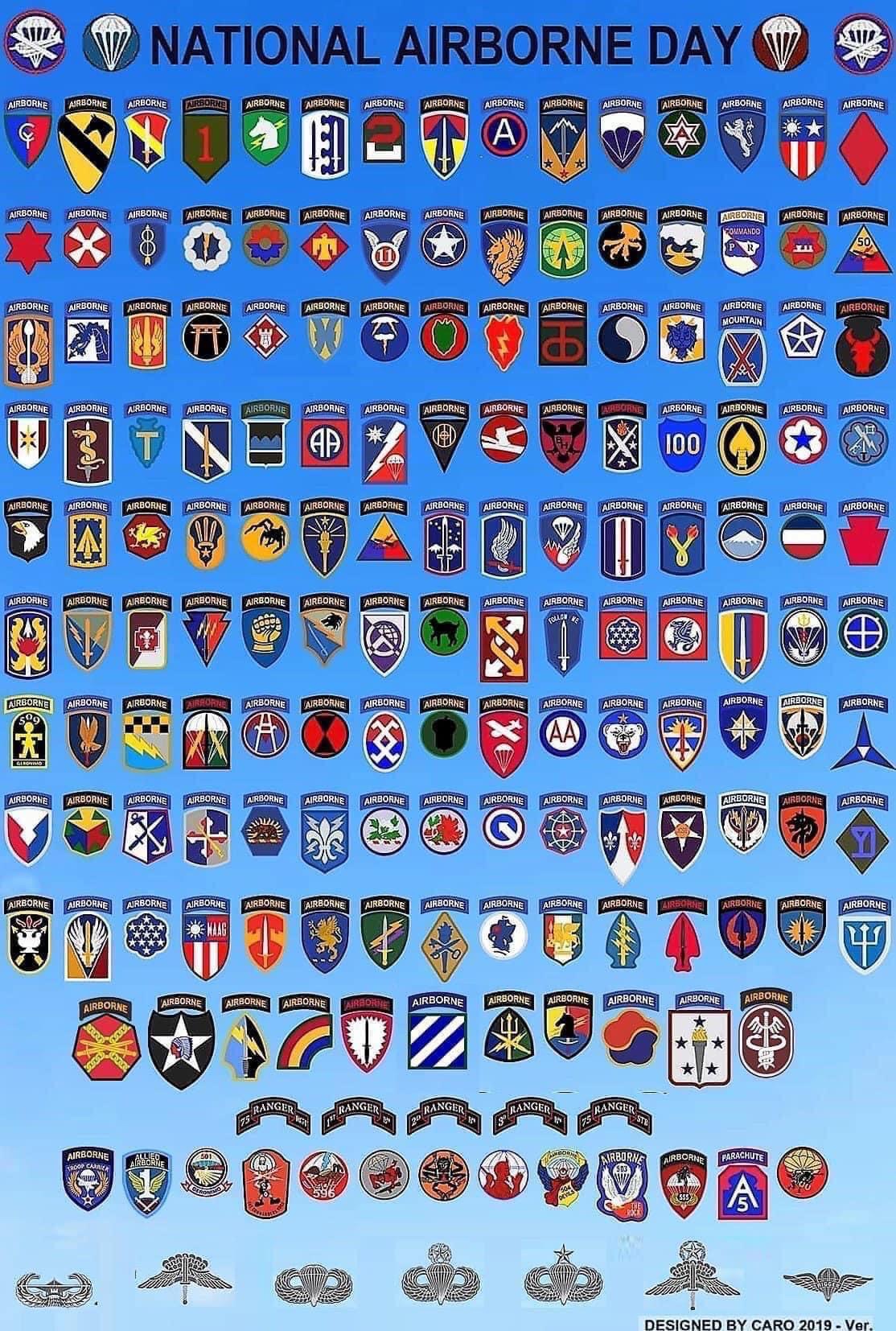

Adding to their handbook series, VSS just released a new handbook on the Sig P320/M17/M18 pistol.

The Sig P320/M17/M18 is pocket reference intended for use by shooters of every level. It gives a quick reference as well as a refresher prior to giving or receiving instruction and contains all the fundamental information needs to operate, maintain, and train with the Sig P320/M17/M18 pistol. It is currently available as a 4”x6” paperback version with plans to release an eBook version in the future.

Authored by Erik Lawrence and Ash Hess.

Erik Lawrence served in the U.S. Army Special Forces and other projects worldwide. His broad range of operational and training experience has perfected his methodology used to help students rapidly advance their skills with a great degree of precision. It revolves around not only the mastery of the basics but a thorough understanding of how and why they work.

Ash Hess was the U.S. Army Senior Writer for Small Arms in the Weapons and Gunnery Branch at the Maneuver Center of Excellence Fort Benning, GA.

https://shop.vig-sec.com/product/sigp320-m17-m18-handbook/

Geissele Automatics is pleased to announce that Michael Hefner is joining our Team as our new President.

Geissele now has 250,000 sqft. of manufacturing space filled with over 135 CNC machines and is preparing for future growth in many facets of the Defense Industry. Mike will take over many of the day to day operations and will work directly with founder Bill in shaping the future of the company.

“I am beyond excited to lead this exceptional organization. Bill and I have discussed many plans and future defense product launches for Geissele Automatics and maybe even a few surprise direction shifts.”

– Mike Hefner

Mike spent 24 years in the US Army, most of which as a Tier One Operator in an SMU. His Army career culminated as a Sergeant Major working in RDT&E and procuring weapon systems and armaments for USASOC. Mike and Bill first met during this time and their first project was bringing the now famous Geissele SSF/SSA triggers into the US Military. There ate many other successful projects that the duo collaborated on prior to Mike’s retirement from the Army in December of 2014.

After military retirement, Mike helped develop suppressors and explosive ignition systems for CGS group. More recently, Mike was President at ZEV Technologies.

REDSTONE ARSENAL, Ala. — Imagine the possibilities of a self-driving vehicle on the battlefield.

Engineers at the U.S. Army Combat Capabilities Development Command Aviation & Missile Center, or AvMC, don’t have to imagine it, they are building it. The Autonomous Multi-Domain Launcher takes a High Mobility Artillery Rocket System — or HIMARS — and modifies it with hardware and software to be controlled remotely and driven autonomously.

“[The Autonomous Multi-Domain Launcher] represents a significant and exciting modernization improvement for the Army,” said Christi Dolbeer, director of DEVCOM Aviation & Missile Center’s Technology Development Directorate. “Adding autonomy to drive mobile launchers and increasing the firing power of those launchers represents a powerful combination. I am very proud of the DEVCOM AvMC and DEVCOM Ground Vehicle Systems Center teams working together to give Soldiers even greater capabilities.”

While it resembles the self-driving cars in the news, the Autonomous Multi-Domain Launcher — or AML — will have capabilities that those vehicles will never possess — but also challenges. Regular autonomous autos operate on established roadways, they aren’t navigating a sometimes treacherous terrain. They also aren’t being fired upon by enemy combatants. Then there is the matter of size.

“We are talking about putting a 36,000-pound vehicle in an area where there will be humans running around,” said Lucas Hunter, AML project manager for AvMC. “Tesla and other companies are working on vehicles that can sense cars in front of them and behind them; they have these nice stripes on the road that tell it, ‘I am getting out of my lane.’ Well, we are driving through open country, we don’t have stripes — we have holes, we have cliffs.”

AML in its current incarnation will look notably different than the final system as the existing cab will eventually be eliminated from the vehicle. Later iterations will also boast a new launcher and increased firing power.

AML was conceptualized as a tool to increase mass fires and “thicken the force,” but what exactly does that translate to in theater?

“AML applies a wingman concept to the Soldiers we already have on the battlefield,” Hunter said. “That spreads out capabilities. So more targets have to be addressed by the enemy. At the same time, it increases the number of rounds that our Soldiers have available which keeps them in the fight longer. With HIMARS, once they fire their six rounds, they have to reload. If you add 12 more, now they are able to support frontline troops three times as long.”

How this new capability will be utilized is currently being explored by the Fires Center of Excellence and the Strategic and Operational Rockets and Missiles Office. Concept testing was conducted in 2021 at Fort Sill, Oklahoma, to demonstrate how the wingman concept might look, emulating a mission with the Precision Strike Missile — the missile being part of the Army’s Long-Range Precision Fire cross-functional initiative and also in the AvMC portfolio.

For Hunter, AML marks not just a landmark paradigm shift for Army battlefield technology, but for the world of robotics itself. With the strides already made in breaking the manual chain and developing the robotic applique kit, it is easy to forget that AML has only been in existence since February 2020.

“There are all kinds of situational awareness challenges that the robotics industry is just now starting to look at,” Hunter said. “AML, which will be called HIMARS Increment 2, has to be able to travel wherever it is told to travel. It has to be able to tell, ‘Hey, there is a cliff right here.’ It has to be able to recognize whatever terrain it is on.

“This is a career field in robotics — how to enhance that situation awareness and do so in passive manners. We need sensors that collect situational awareness data without emitting detectable energy like light or sound. Because you don’t want this to light up like a Christmas tree when the enemy is looking.”

By Katie Davis Skelley, DEVCOM Aviation & Missile Center Public Affairs

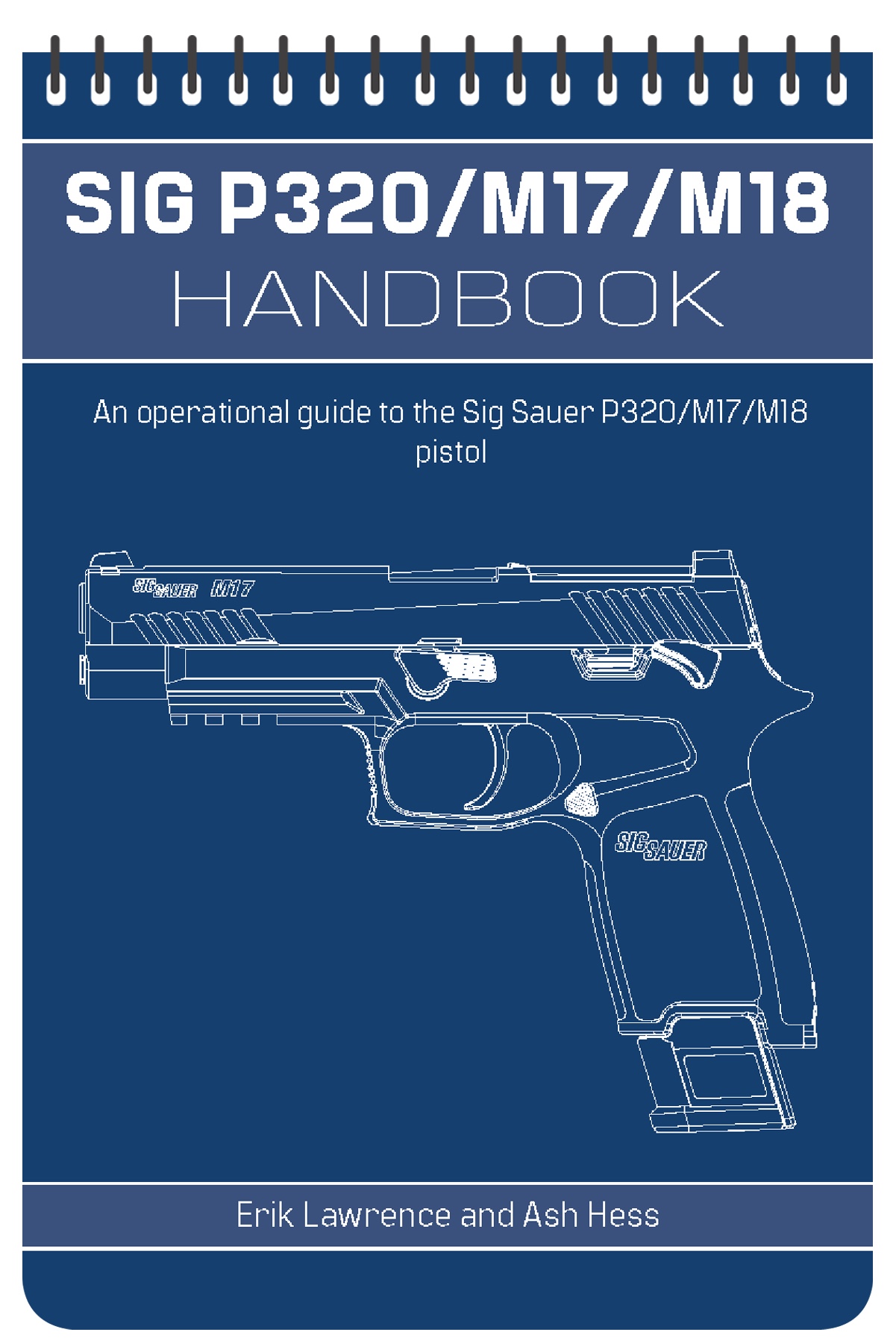

Multi-purpose, lightweight aviation terminal provides high forward and return data rates, worldwide interoperability with military SATCOM, enhancing resilience

15 August 2022, Inmarsat, the world leader in global, mobile satellite communications services and Orbit Communications Systems Ltd., a leading provider of airborne communications solutions, today announced that the Orbit GX30 airborne Ka-band multi-purpose terminal (MPT) has received full type approval for use over Inmarsat’s Global Xpress (GX) network for commercial and military Ka-band (Mil Ka).

The GX30 terminal fulfils the ‘everywhere, all-the-time’ coverage requirements of both military and commercial airborne users and allows government users to roam between commercial Ka-band and Mil Ka services. This low size, weight and power (SWaP) user terminal delivers up to 126 Mbps forward link and up to 29 Mbps return link, maintaining uninterrupted connectivity during all flight phases.

Comprised of three Line Replaceable Units, the GX30 terminal consists of a Radio Frequency antenna assembly, a Ka-band Power Supply Unit and a Modem Unit including Inmarsat’s G-MODMAN II solution.

GX30 can be installed on a range of business jets, military aircraft and uncrewed aerial vehicles (UAVs) and complies with industry standards including MIL-STD-188-164C, RTCA DO-160G, Federal Communications Commission (FCC) 47 CFR 25.218 and European Telecommunications Standards Institute (ETSI) EN 303 978. It is compatible with military satellite systems, making it an ideal choice for government airborne Intelligence, Reconnaissance and Surveillance (ISR) applications.

Tuomo Rutanen, VP Sales and Business Development – Americas, Orbit Communications Systems, said “We are proud of this cooperation with Inmarsat. This GX30 design, coupled with Inmarsat’s Global Xpress network, make it an ideal solution for U.S. government missions that transmit large volumes of data, including military aircraft and UAVs.”

For more than 40 years, Inmarsat has been a major driving force behind technological innovation in mobile satellite communications. GX serves as an example of the company’s innovation as the world’s first and only seamless mobile commercial wideband service available worldwide. Since 2015, GX has been the gold standard for reliable communications across land, sea and air domains for assured mobile connectivity when and where needed. Furthermore, Inmarsat high-capacity steerable antennas that operate in Mil Ka allow authorized military users to access reliable and highly available wideband capacity as part of their own independent network.

Matt Wissler, Chief Technology Officer, Inmarsat Government, said: “With its best-in-class performance plus its low size, weight and power requirements, GX30 is a game changer for demanding aero applications. It ensures access to an easy-to-use, reliable wideband mobility solution for increased agility, interoperability, and worldwide coverage. Inmarsat Government is pleased to continue our partnership with Orbit to deliver innovative, forward-looking satellite communications solutions that support today’s complex missions. Inmarsat is sustaining its market leadership through a substantial investment and a powerful network of technology and manufacturing partners. This ongoing innovation provides a fast, cost-effective solution to the U.S. government’s critical need for resilience, speed, and agility to ensure mission success today and in the future.”

Many jobs Platatac do fly under the radar including the SPUR Tropical Pack in very limited edition DPM (Kumul) Pattern.

The SPUR Tropical’s unique X-Frame system is designed to allow maximum airflow, evaporation and climate control when in hot environments under a heavy physical workload. The X-Frame also helps distribute the pack load onto the hips and small of the back reducing strain.

Available now while they last.

platatac.com/platatac-spur-tropical-pack

The Army Contracting Command – Aberdeen Proving Ground (ACC-APG), Natick Contracting Division, on behalf of US Army Combat Capabilities Development Command – Soldier Center (DEVCOM-SC), anticipates awarding a Cost-Plus-Fixed-Fee (CPFF) contract for the Ground Soldier Technology Workflow, Integration, and eXperience (GS-TWIX) effort.

The Ground Soldier Technology Workflow, Integration, and eXperience (GS-TWIX) effort develops ground Soldier-centric information technology across the operational spectrum of hardware, software, network, and data as well as integrates same to optimize the ground Soldier’s ability to shoot, move and communicate according to the Army Modernization Priorities. GS-TWIX will impact multiple DEVCOM Soldier Center efforts and collaborations including Sensored Soldier, Nett Warrior, Integrated Visual Augmentation System (IVAS), Soldier Integration Facility (SIF), Joint Program Executive Office (JPEO) Chemical Biological Radiological and Nuclear Defense (CBRND), OUSD Research and Engineering (R&E) 5G Tactical Applications for Small Units in Distributed Operations (5GTA-SUDO). These are detailed below:

Sensored Soldier

The goal of Sensored Soldier is to enhanced Multi Domain Operations (MDO) through mission information integration. This task has three sub-tasks that shall provide an interconnected tool suite of actionable decision tools by the end of FY25. First, the Leader Planning & Decision Tools sub-task shall guide Small Unit leaders in the maneuver planning for optimal Soldier physiological, equipment electrical power, network health, and protection using remote sensing drones. Second, the Soldier Equipment Sensing and Integration sub-task Shall provide Soldier Sub-system operational usage status to Small Unit leaders and provide equipment status sensing across the Squad workflow. Lastly, the Remote Sensing and Integration sub-task shall provide hardware, software, network, and data components that provide a Small Unit with a standoff capability to sense threats, maneuver, and communicate same to Small Unit leaders This sub-task shall 1) integrate remote sensing systems and sub-systems, 2) optimize user experience of remote squad sensing components, 3) optimize remote sensing MDO across the Small Unit workflow. Sensored Soldier tasks will transition to Nett Warrior, IVAS, or other Ground Soldier Systems Program of Record (PoR). Contractor shall provide DEVCOM – SC COR a technical report on Sensored Soldier activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Sensored Soldier activities in accordance with CDRL A005 on an annual basis.

Nett Warrior and Ground Soldier System

The contractor shall provide comprehensive and wide-ranging support to the PdM GSS for evolving, maturing, and maintaining NW V3.X system in the areas of software engineering, system engineering, cybersecurity, system architecture, and integration.

The Contractor, in conjunction with the PdM GSS NW SETA contractor, shall ensure the work has a migration path to the NW program record and/or NW Future Initiatives, if the capability needs time to mature. If the Contractor and PdM GSS NW SETA contractor have divergent views on how to ensure a successful transition to the NW program of record of these requirements or how work is divided between both parties, then the Contractor shall promptly notify PdM GSS (GSS Tech Director / NW Chief Engineer) so any required Government clarification / direction can be provided to both parties. The Contractor shall develop solutions that allows application developers to store and distribute information in their own data format. However, the contractor shall leverage server services already provided by the larger TAK ecosystem rather than developing their own server system. Contractor shall provide DEVCOM – SC COR a technical report on Nett Warrior and Ground Soldier System activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Nett Warrior and Ground Soldier System activities in accordance with CDRL A005 on an annual basis.

Ground Soldier Systems Integration

The contractor shall provide technical services for CCDC SC, IVAS, and other government agencies in areas of advanced concepts for information portrayal, sub-system integration, and data analytics: Similar to the IVAS-Soldier Integration Facility (SIF), CCDC SC Mission Information Team requires the development of information portrayal system that interacts with project objectives, project tasks, and both lab and field experimentation operations that includes Nett Warrior-based Soldier worn sensors, ATAK-platoon based sensors, and NW & ATAK web based sensors. Contractor shall provide DEVCOM – SC COR a technical report on Ground Soldier Systems Integration activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Ground Soldier Systems Integration activities in accordance with CDRL A005 on an annual basis.

CBRND Integration with Ground Soldier Systems:

The Joint Program Executive Office for Chemical, Biological, Radiological, and Nuclear Defense (JPEO-CBRND) seeks to design, prototype, test, and document promising wearable capabilities integrated into a single system. The wearables system includes the following components: assistive automation capabilities; wearable, subcutaneous, and implantable devices; cyber secure and scalable wired and wireless architectures; and visualization and decision support tools. The contractor shall provide sub-systems that advance the human integration and current technology for lightweight, integrated wearable systems; Soldier integrated displays and body-worn systems that enhance the Soldier survivability, and situational awareness on the battlefield. Special interest areas include unique human systems integration of data and power systems, miniaturization, increased durability and reliability, and components having low power as well as new power solutions that meet Soldier-portable system requirements for survivability and situational understanding. Specific examples of body- worn system capabilities include: data devices, integrated electronic modules, inter- connections in fabrics, wearable battery technologies, combat identification, tactical engagement simulation capability, system voice control, State-of-the-Art unique interfaces, haptics, neuro-physiological, and physiological/medical sensors and data management, Soldier integration of individual/team weapon system sensors and controls. Contractor shall provide DEVCOM – SC COR a technical report on CBRND Integration with Ground Soldier System activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on CBRND Integration with Ground Soldier Systems in accordance with CDRL A005 on an annual basis.

5G Tactical Applications for Small Units in Distributed Operations (5GTA- SUDO)

The goal of 5GTA-SUDO is to demonstrate the operational impact of a 5G bandwidth improvement to the Integrated Tactical Network (ITN). This task shall develop and demonstrate in an operationally relevant environment, at the Battalion & Company echelon level, multiple ground Soldier tactical applications. Tactical applications shall include 96 hour out load, sensitive site exploitation, sensor to shooter Full Motion Video (FMV) applications, edge device management, ITN multi-network/Primary, Alternative, Contingency, and Emergency (PACE)) router, image product distribution, robotic systems integration and other 5G-based applications. All applications shall be integrated with the software code base and hardware system for either Nett Warrior or IVAS. Contractor shall provide DEVCOM – SC COR a technical report on CBRND Integration with 5GTA-SUDO activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on 5GTA-SUDO in accordance with CDRL A005 on an annual basis.

GS-TWIX specifically seeks to design, develop, and analyze solutions associated with small unit ground Soldier systems and devices as they impact Soldier sub-systems integration, Soldier workflow, and Soldier experience. Historically, Small Unit systems were electronic in nature. Currently, Small Unit systems span the mechanical, electrical, software, network, and data engineering spectrum. Furthermore, the operational space for these solutions is also diverse covering warfighter functions spanning lethality, maneuver, communications, logistics, and protection.

The GS-TWIX effort in FY22 to FY26 will focus on equipment, systems, software, network, and data flow throughout the Soldier workflow as it relates to ground Soldier systems to address optimization in warfighter functions such as lethality, maneuver, communications, logistics, and protection.

The contract will consist of a one year base period and three (3) one year options. This acquisition is a 100% Small Business Set-Aside.

Proposals are due August 21, 2022 by 5:00PM EST (sic).

See the full details here.