With four Republican Guard heavy divisions and the equivalent of a fifth, made up of commandos, Iraq invaded Kuwait on 02 August 1990. Then U.S. President George H. W. Bush quickly said that the United States didn’t condone Iraq’s actions.

During Operation Desert Shield, President Bush formed a coalition (“a collation of the willing” Chapelle) of 35 countries to protect Saudi Arabia and then free Kuwait. On 06 August, the U.S. sent troops to Saudi Arabia, the 82nd Airborne Division and Special Forces were some of the first on the ground (I am sorry if I missed other groups). This began a buildup of combat power in the region, which at its peak had about 600,000 U.S. troops there at one time.

During Desert Shield, some smaller operations took place, including Visit Board Search and Seizure (VBSS), Special Reconnaissance looking for SCUDS and Combat Search and Rescue (CSAR), and running around in Desert Patrol Vehicles (DPVs they would be the first forces into the city of Kuwait) but indeed General Schwarzkopf was not a fan of any Special Forces. He didn’t want to use them for anything. He even had operators from Delta guarding him. On 17 January 1991, Desert Shield turned into Desert Storm with the start of the air campaign. More than 18,000 air missions were flown and more than 116,000 combat air sorties by the U.S. and between 32-40 other countries, including several Arab countries. They dropped 88,500 tons of bombs on the enemy.

On 28 February 91, the ground war started again; a lot of groups played different roles in the invasion. Special Forces Groups conducted special reconnaissance, CSAR, and Direct-Action missions.

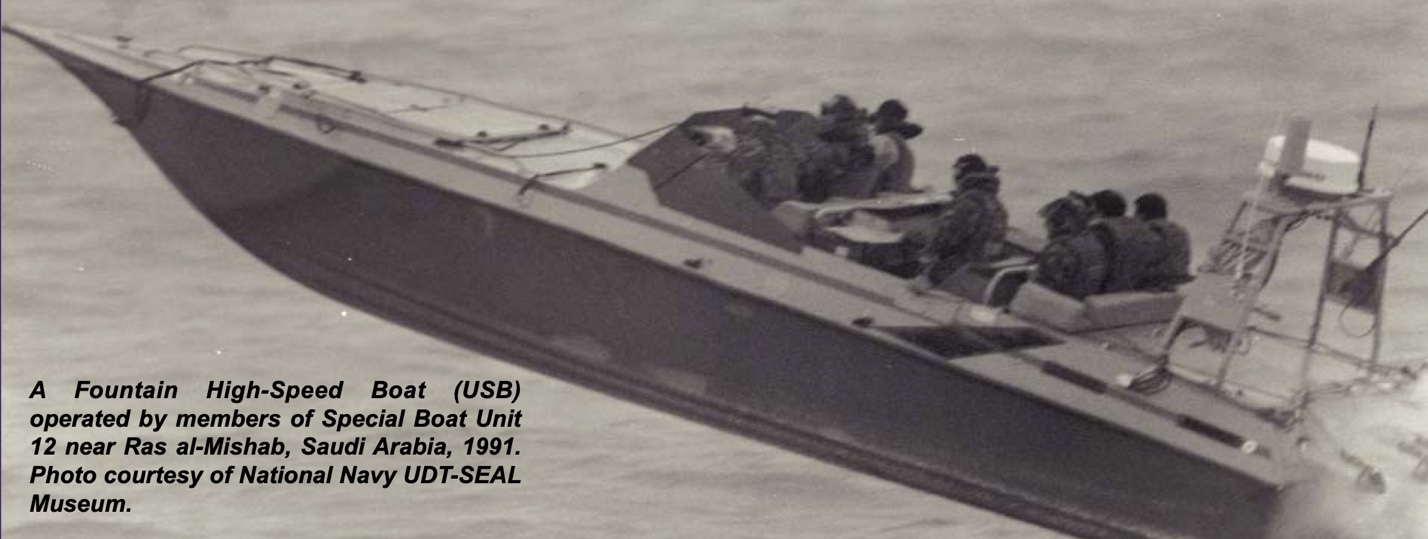

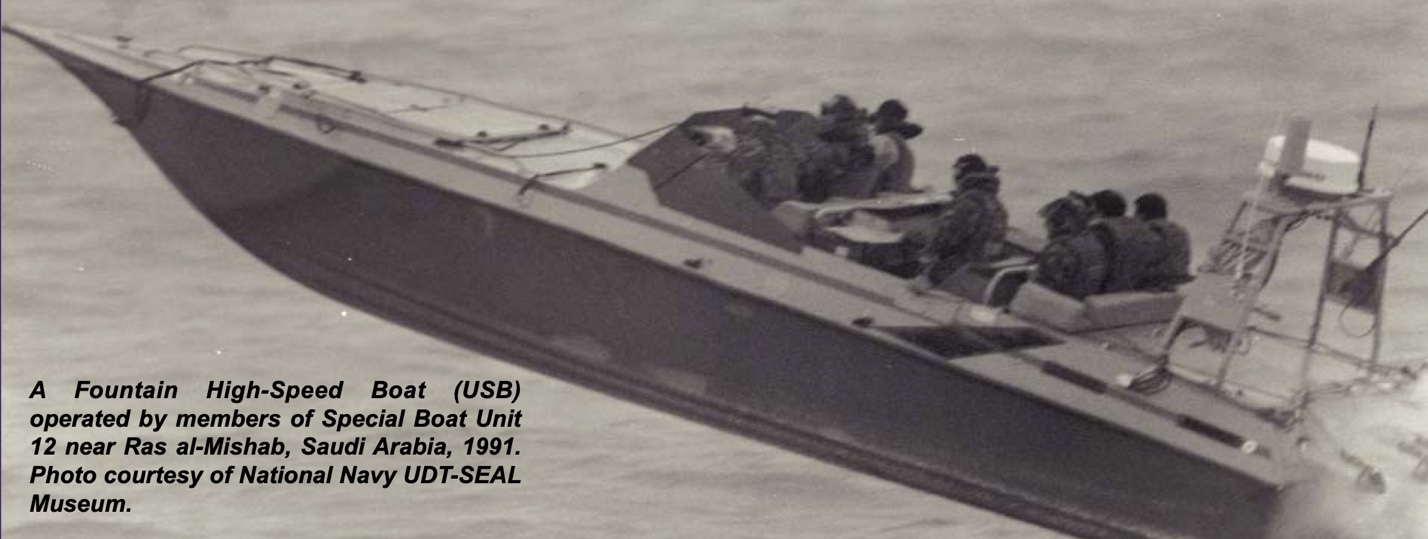

Naval Special Warfare (NSW) Group One had run NSW Task Group Center based out of Ras Al-Mishab. There were SEAL platoons from almost all west coast teams, including a Platoon for SEAL Team Five and a boat Det from Special Boat Unit 12.

One of the Platoons from SEAL Team Five and the High-Speed Boat (HSB/ HSAC )Det from SBU-12 was tasked with conducting an over the horizon beach attack to fool the Iraqis into thinking a full-scale amphibious landing was going to happen. To help with this, over the horizon, off the coast of Kuwait, was an armada of ships, each carrying approximately 17,000 Marines, all ready to land on the beaches. But, the only amphibious assault of Kuwait would be carried out by a half-dozen Navy SEALs. Lt. Tom Dietz (the only reason I am using his name as this is well documented) and five other SEALs would drive up the coast from Ras al-Mishab in a pair of Fountain-33 HSBC as the sunset on Saturday, 23 February, the day before the allies were scheduled to commence the ground campaign. The Fountains, propelled by 1,000-horsepower MerCruiser engines, sped up the Kuwaiti coastline at 40 miles per hour. This might sound fun, and at first, it is, but it is not the best on the knees. That night, the water temperature was a bone-chilling 50 degrees Fahrenheit in the gulf. It was even more concerning because it was plagued with mines. The SBU 12 boat guys sailed blindly, with their lights turned off, knowing that if their thin-shelled boats encountered a mine, it would not end well for them. When they entered the minefield, they traveled slowly at first; then, after some talking realized fast or slowed if they hit a mine, it would be not good, so travel fast was decided to be the best plan.

Dietz’s speedboat came to a halt 15 miles off the coast of Kuwait at approximately 10 p.m. His team was able to free the Zodiac rubber raiding boat attached to the bow. After swimming up to Kuwaiti beaches in stealth for a month, searching for prospective amphibious landing sites, the SEALs discovered that all of them were well fortified and mined, indicating that they would be difficult to reach. Dietz’s two motorized Zodiacs made their way gently to the coast, halting every few miles so the commandos could look and hear what was going on.

The F470 Zodiac stopped about five hundred yards from the beach, and the swimmer were launched. Each carried haversack with C4, which they would use to string buoys out along the swim to the beach. These buoys with a diameter of four feet would give the impression that the buoys were marking impending amphibious ships. The beach charges were set for 1 a.m. local time about 3 hours before the Collation forces began breaching the minefields along the Kuwait border on Sunday, 24 February. This would give the Iraqis time to move troops east to the coast, where the fake invasion was thought to be happening. The importance of time could not be overstated. For the Iraqis to respond effectively, they must be allowed to do so by moving forces east in response to the diversion rather than reinforcing soldiers in the west, where the actual attack would occur.

The SEALS kept an eye on the coast while swimming toward the beach together. Each swimmer had an MP5 with them, and SBU-12 HSP was slowly making their way towards the beach to help in an emergency and for a follow-on mission after the platoon was back to the F470s. The team would stop and look at the beach with a pocket night-vision scope every hundred yards. In the early 90s, items like that were not as waterproof as they are now, so it was stored in a good old plastic bag. They even made all black surfboards sent from Coronado to carry radios. Because of the smoke from the oil wells burning, the night seemed even more ominous. The sand on the beach was white and looked like it had just snowed out even though it was sand.

The crew split out on the shoreline and unloaded its haversacks in around a foot of water. The rest of the team followed suit. Dietz instructed the timers to be set by using hand signals. The SEALs exfilled keeping an eye on the beach. After closing in on the Zodiacs, the HSBC opened up on the shore with their .50-caliber machine guns for half an hour in an attempt to make the Iraqis think a more significant force was attacking the coastal fortifications. Two-pound charges were dropped off the sides of the boats and exploded every five minutes. Around the same time, the USS Missouri battleship opened up with her 16in guns, firing 2700lbs shells over the heads of the guys in the boats. They were firing at the Iraqi command bunkers near the Kuwaiti coastline, helping with the illusion that an American-led amphibious assault on occupied Kuwait would be on the horizon. At precisely 1 a.m., explosives on the beach went off. Dietz radioed back the code word “Pamela,” meaning “mission completed.”

After a brief pause, Missouri fired once more into Iraqi-occupied Kuwait. This time, the Marine Corps dispatched ten helicopters to mimic a landing force on the ground in Iraq. The Iraqis launched anti-ship missiles at Missouri, but a British ship intercepted and destroyed the lone missile that posed a severe threat to the warship. Coalition jets were able to locate and destroy the missile launch point quickly.

As a result of the bombardment’s effectiveness, Iraqi troops sought to surrender to the drone (from the USS Missouri) that flew back over the target area, waving little white flags. For the first time in history, troops would try and surrender to a drone.

Hundreds of lives were saved during Desert Storm due to this fictitious amphibious assault by Naval Special Warfare. After six weeks of air attacks, the ground campaign only took 100 hours before Kuwait was freed. On 28 February, a ceasefire was established, effectively putting an end to the hostilities until Iraqi dictator Saddam Hussein agreed to the peace agreement provisions. The coalition forces suffered a total of 300 casualties in the combat, which is significantly less than the number of deaths they would have suffered if the Iraqi troops had been permitted to concentrate on the actual threat.