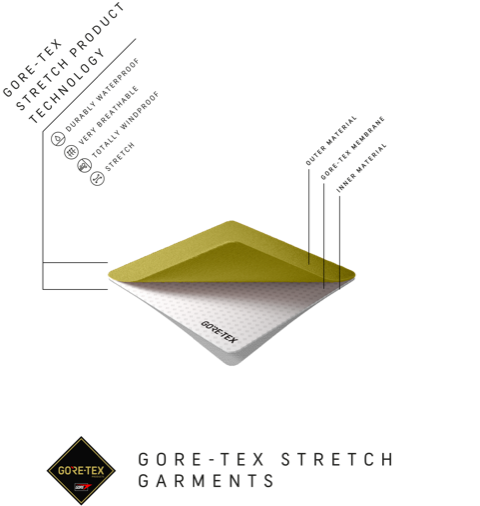

GORE-TEX Stretch combines the highest level of protection with optimized comfort to deliver protection in the most demanding environments. Building on the recognized performances of durable waterproof, windproof, and breathability, GORE-TEX stretch fabric technology offers the additional benefits; reduced thermal burden, high agility and mobility, and improved equipment integration. This is achieved through an adaptive fit that reduces air gaps and leads to a more optimized design with less bulk. The fabric also delivers high flexibility in cold climates, and noise reduction. The stretch ePTFE membrane technology enables the design and construction of garments to have a more tailored fit, which improves the garments evaporative resistance and increases breathability by 25%.

Garments designed with GORE-TEX PYRAD® technology provide heat, flame, and flash-fire protection for defense personnel. To highlight this technology at AUSA, the updated Flame-Resistant Environmental Ensemble (FREE) EWOL jacket and trouser will be on display. This updated version will be leveraging GORE-TEX PYRAD® technology. This versatile technology offers the durable waterproof, windproof, and breathable protection you would expect of GORE-TEX products and provides some of the lightest weight, low bulk, flame-retardant garments on the market.

Building on Gore’s history of leveraging technology and science to improve comfort and functionality, GORE-TEX PYRAD® Fabric advances performance while maintaining protection. Products made with GORE-TEX PYRAD® Technology are breathable, lightweight, and flexible, and offer improved comfort during the most demanding tasks. The fabrics also pick up less water and dry faster than alternative flame-retardant fabrics.

Leveraging silica aerogel – the world’s best solid insulator – GORE-TEX THERMIUM™ insulation can provide unparalleled warmth without adding bulk. GORE-TEX THERMIUM™ Insulation can be strategically integrated into areas where it’s needed the most. Gore will feature the technology at AUSA in both Gloves and Footwear. A fully insulated boot from Belleville along with the uniquely designed APEX boot from ALTAMA will be on display. The ALTAMA APEX boot will showcase our most breathable GORE-TEX laminate with strategically placed THERMIUM™ insulation. Combined with new soling technology from Michelin, the ALTAMA APEX boot will provide a more versatile combat boot offering performance within a wider temperature range.

W. L. Gore & Associates is a global materials science company dedicated to transforming industries and improving lives. Since 1958, Gore has solved complex technical challenges in demanding environments, from outer space to the world’s highest peaks to the inner workings of the human body. With more than 10,500 Associates and strong, team-oriented culture, Gore generates annual revenues of $3.7 billion.