Dropping 27 April, Lindnerhof Taktik’s lightest Plate carrier yet. The MX224 Uktralight Plate Carrier features their proprietary MX material, a laser cut multiaxial laminate which is paired with their patented hook buckle.

Dropping 27 April, Lindnerhof Taktik’s lightest Plate carrier yet. The MX224 Uktralight Plate Carrier features their proprietary MX material, a laser cut multiaxial laminate which is paired with their patented hook buckle.

NATICK, Mass. — Researchers at the U.S. Army Combat Capabilities Development Command Soldier Center, or DEVCOM SC, have developed a body armor questionnaire to help improve body armor for female users specifically and for all body armor users in general.

The researchers at DEVCOM SC — who are longtime experts in Soldier protection, human factors and gathering/analyzing Soldier input — are investigating body armor fit and related issues, and how those issues impact the ability of users to perform their mission.

Participation from current and past users of body armor will provide researchers with insight into user needs and ways to make improvements. Data will be collected from a questionnaire completed by eligible individuals.

The questionnaire is part of DEVCOM SC’s larger effort to support the Female Body Armor Modernization Act. In support of the act, DEVCOM SC is investigating and developing body armor system improvements specifically focused on women as well as improvements that will benefit both male and female Soldiers. DEVCOM SC’s Applied Ergonomics Team and the Consumer Research Team, both part of DEVCOM SC’s Soldier Effectiveness Directorate, have worked together to develop the questionnaire.

Blake Mitchell, team leader of the Applied Ergonomics Team and lead for the Anthropometric Study for the Female Body Armor Modernization program, explained that the questionnaire will help “to identify the predominant fit and performance issues, as well as the body armor system sizing and issuance process experienced by women in the Army.”

Mitchell explained that the questionnaire goes into considerable depth in its attempt to identify what the primary issues are in a way that can allow for design improvements. The questionnaire gives participants the means to identify ways they are not fully protected, any discomfort they experience — both short or long term — and how issues with fit may impede their ability to do their job.

“We want potential participants to understand the importance of completing this survey, because it takes time to answer all questions honestly and thoroughly, particularly for those who have more experience with body armor,” said Wendy Johnson, a research psychologist on the Consumer Research Team. “In order to make the survey more convenient and to accommodate their schedules, participants have up to seven days to complete the survey once they begin.”

The questionnaire is aimed at women in the Army, but all genders are welcome to respond. The research team hopes to use data from male respondents to better understand their general fit and performance issues. Researchers are also interested in gathering opinions of body armor users from the National Guard and the Reserves, as well as individuals who have recently separated from the military.

“We hope to elicit responses from a wide variety of mission areas across the military – from people that only have to wear body armor occasionally to those that wear it day and night for extended periods of time,” said Mitchell. “Having data from a broad array of users will allow us more power in how we understand and interpret the data, and aid in the better design of future systems to accommodate a broader range of the user population.”

The questionnaire asks respondents relevant questions about their body shape and size, as well as their experiences with, and performance impacts due to, body armor use. In addition to identifying the specific body armor elements that need to be improved, researchers also hope to find out what is working well.

“Researchers will summarize the information derived from this questionnaire and will make it available to designers, manufacturers and acquisition personnel,” said Mitchell. “Key issues will be grouped based on demographic and anthropometric descriptors to lead to a better understanding of how to improve fit and performance.”

As part of their larger effort to improve female body armor, DEVCOM SC researchers are also using data from the 2012 Anthropometric Survey, or ANSUR II, to better understand the size and shape of women who make up the U.S. Army. ANSUR II includes direct measurements and three-dimensional whole-body scans. ANSUR II was executed by DEVCOM SC and is one of the world’s largest and most comprehensive anthropometric surveys. It provides invaluable data that aids the design and optimization of a wide range of products.

The body armor questionnaire is part of DEVCOM SC’s ongoing emphasis on Soldier input as a key component in all research and product development.

“The Soldier Center wants to ensure that all of the products we support meet the requirements of all Soldiers so they can complete their mission and do their job without creating unneeded or additional burdens for them,” said Mitchell. “This questionnaire will provide specific information on Soldier’s preferences and experiences for body armor in their own voice.”

Data gathered from DEVCOM SC’s questionnaire will be used to improve future body armor development efforts for the Army. Navy body armor designers and project officers have also expressed interest in the results and have requested information and summary data on female Sailors who have experience with certain Navy body armor systems, as responses from other services are also being collected. The Soldier Center plans to have a summary of results by the end of the fiscal year.

If you are interested in participating in the questionnaire, it is available at online.

By Jane Benson, DEVCOM SC Public Affairs

Manassas, Virginia – Aimpoint, the originator and worldwide leader in reflex sighting technology, has been awarded a new contract for supply of the Aimpoint® FCS13RE Fire Control Systems to the U.S. Military. The system is currently being deployed as the primary Fire Control on the M3E1 MAAWS lightweight 84mm Carl-Gustaf produced by SAAB Dynamics for use by the U.S. Army, U.S. Marine Corps, and U.S. Special Operations Command.

The FCS13RE is a direct view, Dynamic Universal Reflex Sight, which utilizes an integrated laser range finder and ballistic computer to give the gunner an aiming point corrected for range, type of munition, terrain angle, and environmental conditions. In addition to the 84mm Carl-Gustaf, the system can also be utilized on other weapons including the AT4, 40mm high velocity grenade launchers (Mk19, Mk47, and GMG), .50 caliber heavy machine guns (M2), and the M134D Minigun. The FCS13RE provides an extremely high probability of first round hits on both stationary and moving targets during day and night. The system can be enhanced with a magnifier, a thermal imager, and is compatible with all generations of military night vision.

“We are proud that the Aimpoint Fire Control System was the selected optic for the MAAWS weapon platform.” said Thane Smith, Professional Sales Director at Aimpoint Inc. “The FCS13RE has a proven hit probably of over 90% for the max effective range of the Carl Gustaf weapon system and is also capable of mounting to various crew-served weapons. Aimpoint will continue to produce the highest quality weapon optics that increase lethality and survivability of our service members.”

For more information on the Aimpoint FCS13RE or any other Aimpoint product, visit the company’s webpage: www.aimpoint.com/products/product-series/fcs-series

By far the most impressive gear I saw at last year’s Outdoor Retailer Summer Market was their new Go line of outdoor furniture and accessories.

The whole line is cool, but my favorite is the Hydration Jug. There’s a bit of a joke in the capacity. Their line of thinking was that although other water jugs holds 10 liters, their’s goes to 11.

The HYD-J11 features a 63 mm Nalgene-style opening for easy attachment of water filters and accessories. There’s an additional opening which is big enough to allow access to the interior for thorough cleaning. It’s also constructed from BPA-free, food-grade LDPE.

Finally, the design integrates built-in tiedown guides and removable webbed carry handles. Offered in Ash, Black and Glacier. Unfortunately, the new accessory faucet isn’t out yet but it does come with a spigot.

www.dometic.com/en-us/outdoor/lp/dometic-go

Jankel, a world-leader in the design and manufacture of high-specification defence, security and NGO protection systems, has announced the receipt of a follow-on order for x10 of their twin-cab pickup variant Toyota LC200. The order comes from an undisclosed customer who previously purchased armoured variants of the same vehicle; a contract that was announced in February 2021. In addition to these 10 vehicles, Jankel has recently received orders totalling a further 20 armoured LC200 vehicles from undisclosed customers, globally, sweeping up the last of the LC200 available stock.

With the Toyota LC200 base platform having now gone out of production, the customer secured the base vehicles for this project using Jankel’s “buy now – armour later” scheme to ensure they had sufficient stock of the outgoing LC200’s, prior to conversion. Jankel are highlighting this conversion as an example of how they can adapt any vehicle to meet customer needs and fill specific capability gaps in the specialist protected vehicle market. With no new LC200’s now available, The Jankel pickup design has the potential to become an after-market modification carried out on in-service LC200’s.

Jankel has integrated an existing and proven pickup design with the also proven and certified, Jankel LC200 base platform. Bringing together the strengths of both designs into one offering has resulted in the variant extending the operability through a gain of an additional 650mm in wheelbase. This combined with a heavy-duty rear axle upgrade delivers an increase in Gross Vehicle Mass (GVM-4495kg) and payload (up to 1500kg depending on specification), whilst retaining the existing crew-cab dimensions and space. The technique of lengthening the chassis and incorporating the modular and adaptable flatbed pickup pod is easily adapted to other commonly armoured light vehicles.

In addition to the increased payload and the usable flat 1900mm x 1700mm load bed space, the vehicle can be configured to deliver a number of automotive and user-orientated tactical capability enhancements such as: run-flats; improved brakes; tuned suspension; EMC suppression; fire suppression system; 24v communications installation; door deadbolts; escape hatch; gun ports; weapons mounts; tactical lighting, lightweight Jankel mesh seats and a PA/siren. The lightweight flat-bed can be delivered with a canopy or a hard-top and includes folding/removable sides and integrated modular storage bins.

Looking ahead, Jankel are currently developing their armoured LC300 design that is scheduled for a product launch later in 2022. The result of an extensive design, development and testing programme, Jankel’s new LC300 will deliver ‘best in class’ protection, safety, capability and functionality. Leveraging Jankel’s considerable experience in the field of Civilian Armoured Vehicles (CAVs) gained over many years of high-quality service to the defence, security and NGO sectors, the new LC300 will be an exciting addition to Jankel’s range.

Andrew Jankel, Chairman at Jankel Group said: “We first developed the new pickup variant of our Hot Formed Armoured LC200 as a result of receiving an order from an existing customer in 2021 and we’re delighted to have received this follow-on order for an additional x10 un-armoured variants, underling their confidence in Jankel to deliver”. He added: “Looking ahead, we’ll be launching our armoured Toyota LC300 later this year which is undergoing an extensive design and development programme. We have listened carefully to our customers evolving needs and I believe it will be a best in class, quality product”.

At Angel Armor we are looking for a creative genius with a strong streak of the practical, a person who pays attention to detail, embraces technology and has the uncanny ability to revolutionize and render amazing, even the humblest of products.

This position works within the product development group with the focus of integrating the core ballistic technologies of Angel Armor within the OEM vehicle market. This role will work closely with the R&D group to understand new technologies, conceptualize potential product directions, refine viable paths; development and document design specifications and work closely with the manufacturing and quality teams to ensure the end product moves efficiently into production. A strong passion for product, attention to detail and good cross-functional communication skills are essential to success within this highly motivated, hardworking start up environment. We are also looking for a candidate who believes in and lives our Core Values: Integrity, Humility and Perseverance.

Duties & Responsibilities Include:

· Participate in marketing research and conduct product design research

· Communicate design ideas using sketches and computer generated visualization tools including Adobe Illustrator and Photoshop

· Ensure project goals are achieved with respect to scheduling, cost, and deliverables

· Develop 3D models of mechanical components and assemblies

· Draft Sketches and illustrations of potential products or work on enhancing an existing product to make it more appealing to customers.

· Read and create blueprints, detailed drawings, or computer-aided designs to demonstrate product potential

· Develop and fabricate prototype assemblies

• Systemic approach to work including the identification and creation of processes to ensure future repeatability, efficiency and quantity

• Interface with existing and future suppliers

Qualifications:

• Proficiency with Solid Works CAD and drafting required

• Fabrication and prototype experience required

• Experience with composite materials and manufacturing processes is desired

• Experience within the automotive industry is preferable

• Experience within the cut and sew industry is preferable

• Enjoy and value hands on experience

Requirements:

• Minimum 3 years of product development or design experience required

• BA in Mechanical Engineering, BFA in Industrial Design, or equivalent experience required

• Strong written and verbal communication skills

• Self-Motivated and appropriately assertive in pursuing and achieving objectives

• Must possess qualities and values of Angel Armor: Integrity, Humility, Perspective, Vision, Fire, and Fun

• Must be legally authorized to work in the United States

Physical Requirements:

• Daily activities involve working within an office environment and may require walking between office areas and/or stairs

• Ability to be on the production floor for extended times may be required

• Ability to work on the production floor to create prototype parts will be required

• Must be able to lift, carry, drag, pull or push up to 50 pounds

Job Type: Full-time

Pay: $60,000.00 – $70,000.00 per year

Benefits:

• 401(k)

• 401(k) matching

• Dental insurance

• Health insurance

• Life insurance

• Paid time off

• Vision insurance

Schedule:

• 8 hour shift

• Monday to Friday

Work Location: One location

Applicants send resumes to teresa.nugent@blueocean-inc.com.

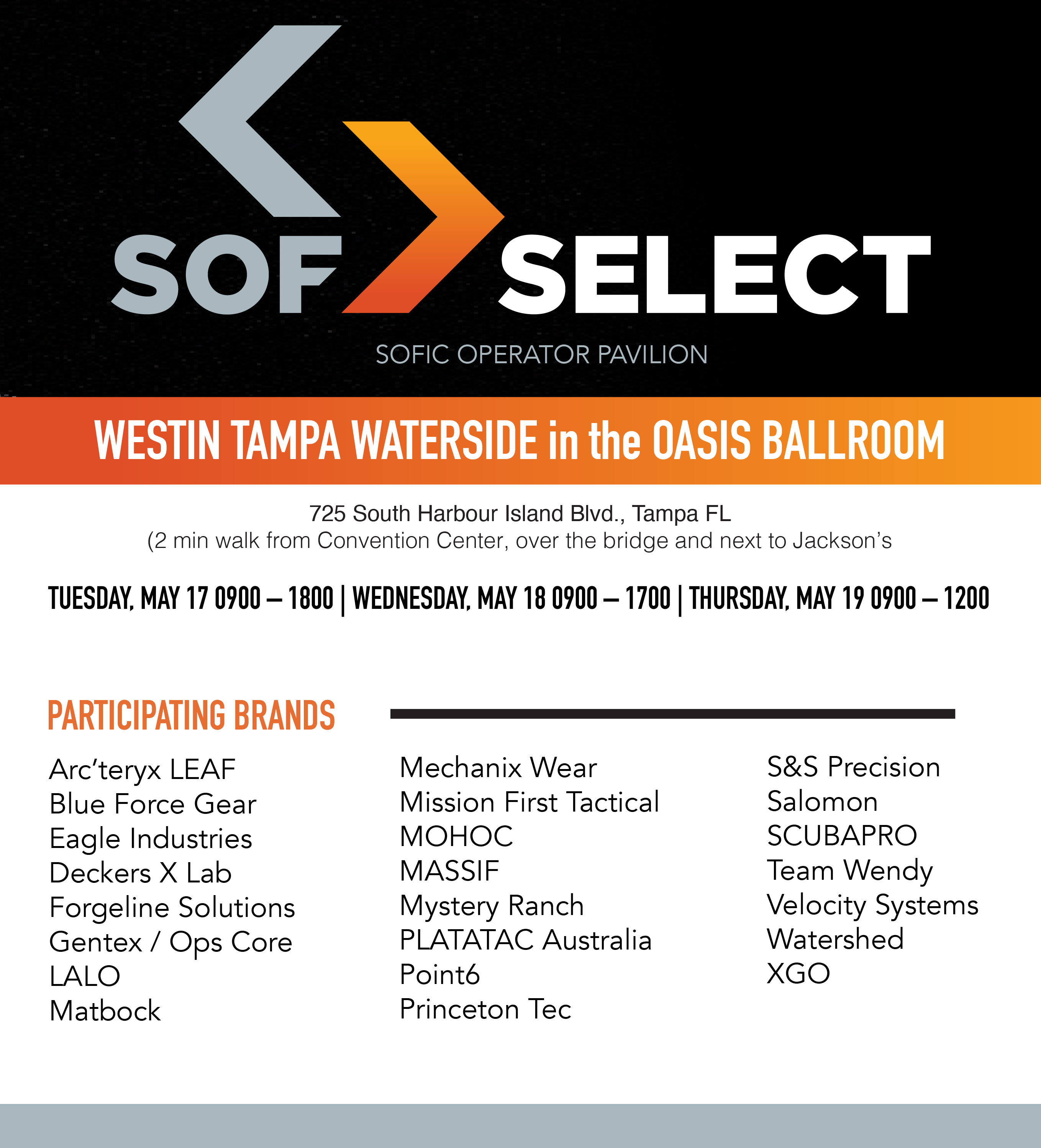

Many of you have either attended SOF SELECT in past years or seen our coverage of the event which coincides with SOFIC. After a two year hiatus due to COVID, we are happy to tell you that SOF Select is scheduled for 17-19 May at the Westin Tampa Waterside, conveniently right across the bridge from the Tampa Convention Center.

SOF SELECT showcases those smaller companies that make a big, direct impact om the capabilities of SOF.

What you need to know:

-Pre-registration is not required

-No on-site check in

-SOFIC conference pass is not required to access SOF SELECT

-Connect with your brand POCs for more details or to schedule a time to connect at the show

See you there!

Event details or questions, please contact Cove Event Management llc, rebecca@coveevents.com.

SWANSBORO, N.C. – April 25, 2022 – Carry your medical gear comfortably with the 247 Trauma WrapTM.

In the tactical community, one of the most overlooked items can be medical equipment. Depending on your mission, medical equipment can take up a significant amount of “real-estate” on the body, however, High Speed Gear® offers a solution for individuals to carry life-saving medical equipment while increasing the amount of space on the body to remain lethal.

High Speed Gear® offers a 247 Trauma WrapTM that is worn around the ankle for fast and comfortable everyday wear. The 247 Trauma WrapTM allows users to conceal carry their medical gear around the ankle or over a boot. The trauma wrap holds the essentials for stabilizing a gunshot wound and has the option for expandable storage for extra supplies.

“Our mission is to provide tactical gear to our customers that they can depend on; no matter if they are law enforcement, military, or a responsibly armed citizen.” Said Bill Babboni, HSGI® Chief Operating Officer. “The 247 Trauma WrapTM allows you to save room on your kit, while still being able to access your medical gear quickly in case of an emergency.”

The High Speed Gear® 247 Trauma WrapTM is a must-have for all outdoor enthusiasts, first responders and military forces.

Specs:

-Designed for one tourniquet, combat gauze, compact compression bandage and nitrile gloves

-Expandable storage will also fit chest seals, gauze and a clothing cutter, if desired

-Glove pocket on elastic strap folds flat when not used

-Neoprene padding behind tourniquet pocket protects ankle from hard contact with tourniquet and adds grip

-Features breathable spacer mesh for comfort

-Elastic strap offers adaptable fit over the ankle or a boot