Thales RapidRanger – a modular integrated mobile weapon system – firing StarStreak

On Ukraine’s front lines, a small robot trawls through the dark, laden with supplies. Against long odds, this Uncrewed Ground Vehicle delivers a lifeline to the warfighter who depends on it. Whether platforms can go the distance and deliver the required effect is increasingly defined by the mission systems they’re equipped with – the sensor suites, autonomy modules and C4ISR capabilities that turn a technological edge into an advantage.

As Human Autonomy Teams go, this serves as just one discrete example among many. Platforms, of course, predominate. However, their ability to achieve the desired results increasingly depends on the mission systems they are equipped with, which transform technological superiority into a competitive advantage.

Mission systems: the ‘secret sauce’ behind a platform’s value and lethality

As the Minister of State for the Armed Forces warned of the “shadow of war knocking on Europe’s door”, UK MoD is shifting gears to meet an urgent, unerring need: to keep its armed forces agile enough to stay ahead of the threat and lethal enough to deter it altogether. The role of platforms in meeting this need is not in doubt. But if they are doing the heavy lifting, then it is the mission systems on top that fine-tune the solution.

One only has to consider the £1bn earmarked for the Digital Targeting Web, described by General Sir Jim Hockenhull as bringing “a step change in lethality”, to get an idea of what that solution could look like: an interconnected network of AI-enabled sensors, deciders and effectors to help British Army operators, in the context of Project ASGARD, see first and strike fast.

The timing of the Army’s new framing as a ‘20-40-40’ force is not a coincidence. On paper, 20% of its combat capability will come from technologically advanced, high-spec “survivable platforms”. In practice, these platforms – and their operators – will be able to punch above their weight.

Behind all the speeches, strategies and initiatives is an unequivocally clear desired strategic end state. The British Army must become – and must remain – a protected, connected, digitally-enabled and absolutely lethal force.

Augmenting the platform to enhance the operator

If the ‘ends’ have been well-defined, then the ‘ways and means’ are increasingly delivered by mission systems that can make operators safer, more decisive, more dangerous and more situationally aware beyond the metal hull.

“Take the TrueHunter gimbal sight. Its ability to identify and track targets on the move – and at increased range – helps commanders and gunners deftly coordinate and execute recce-strike operations, enabled by a seamless handover of targets.

“Combine this with the RS4 stabilised weapons system, TrueGuardian Threat Detection and Thales’ DigitalCrew, and hunter-killer teams become – like the platforms they operate – far greater than the sum of the parts: a network of organic and synthetic eyes, ears and instinct to deliver tactical advantage,” says Jonathan, Head of Land Sales at Thales.

DigitalCrew™, a domain, platform and sensor-agnostic suite of algorithms, assists soldiers in armoured vehicles. It enhances and augments what they ‘see’ through sensors and alerts them to what is different, dangerous, or of interest.

Such a reality is neither remote nor unattainable. GVA-compliant platforms like the Hippo Multipower Raptor UGV – designed to UK MoD open-architecture standards that allow rapid integration and upgrade of mission systems – are rolling out of the lab, off the production line and on to where they are needed most.

Rigorous experimentation for real-world implementation

Similarly, initiatives like the Land Digital Robotics and Autonomous Systems Integration Capability (L-DRIC), a DSTL-funded programme, are acting both as vanguard and testbed for this sort of capability. The aim is to give operators the means of sensing the battlefield without stepping foot or training eyes on it. From a technical perspective, this involves beyond visual line of sight operation of multiple uncrewed ground and air systems from a crewed platform that’s positioned away from the immediate action.

“Working alongside DSTL, Catalyst and Digital Concepts Engineering, Thales developed trials for L-DRIC during which a single operator controlled three uncrewed vehicles – including Raptor – demonstrating how robotic and autonomous systems (RAS) can be integrated with crewed command vehicles through a unified digital system,” says Jonathan.

Although three uncrewed vehicles were used in the recent trials, this is by no means the limit of the capability. It would be possible to also include fixed winged capability as L-DRIC emulates a combat platform system with full UK DEF STAN 23-009 GVA installation. With sufficient processing power, the digital twin eco-system could incorporate a whole battlegroup simulation that could be rapidly configured down to individual sensor and effector levels. The extension of GVA electronic architecture into RAS force integration has been critical to enabling the rapid sharing of information across the whole eco-system.

This is a UK first. It will not be the last. The physical platforms and systems involved in L-DRIC were digitally twinned, allowing for rapid testing and scaling of new and existing capabilities in a virtual environment without the effort, cost and risk of buying hardware and conducting physical trials.

The lessons learned and successes earned from L-DRIC can be laced through wider defence business: how to pull a TRL-6 capability through to fieldable product at speed; how to help MOD make the most of its existing investments; and how to keep operators lethal without making them targets.

The procurement imperative: investing in software-enhanced mission systems

With every passing week comes new peril, a stark warning, a technology turned on – then turned on the West. Threats proliferate and cross-pollinate across domains. Any advantage gained by either side is slim and fleeting. This is neither new nor news; the nature of war remains unchanged just as its character can become unrecognisable in months.

When it comes to armoured mobility, heavy metal might be enough to make do but it is not enough to make better. The platforms exist – and where they don’t, the programmes to replace them do. As the shadow of war starts knocking louder and louder, what is needed are three distinct but complementary things:

- a focus on rapidly upgradable, spirally-developed mission systems;

- a network of highly qualified, high-quality SMEs to design, develop and deliver the systems, and

- integrators who can ensure these systems all contribute to a faster, tighter and more lethal sensor-to-shooter chain.

For these to work – and work well – we need common standards, open architectures and a platform-agnostic approach to sensors, data fusion and effectors. Technologically, we are already there. Technically, we are not far behind. But if the UK is to meet its aggressive lethality goals, then procurement and upgrade strategy must recognise that money is best spent on the software-enhanced mission systems that turn platforms into force multipliers.

Thales RapidDestroyer – Radio Frequency Directed Energy Weapons (RFDEW)

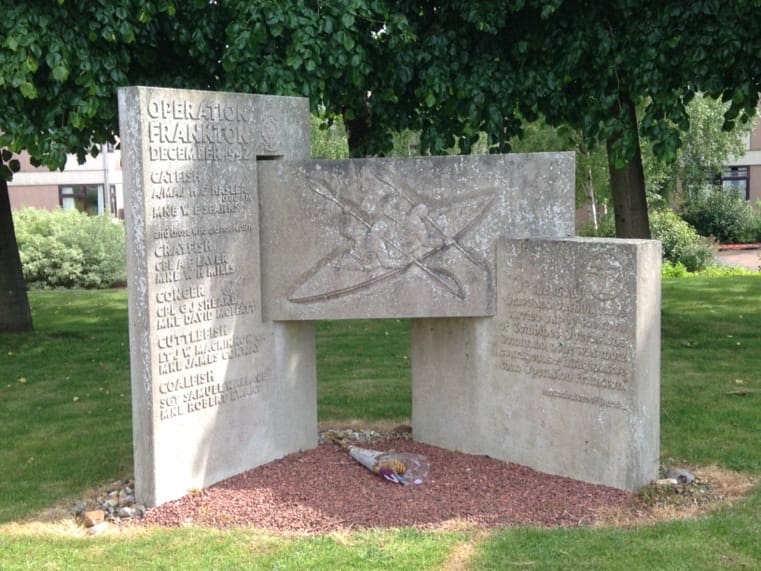

Hasler proposed a solution to a persistent operational problem: German shipping operating from the occupied port of Bordeaux, which had proven difficult for British Bomber Command to interdict. His plan envisioned a ten-man raiding force launched by submarine outside the mouth of the Gironde Estuary. From there, the team would paddle more than eighty miles during periods of limited visibility, emplace limpet mines on enemy shipping, and then evade by any means available, with the ultimate goal of returning to the United Kingdom.

Hasler proposed a solution to a persistent operational problem: German shipping operating from the occupied port of Bordeaux, which had proven difficult for British Bomber Command to interdict. His plan envisioned a ten-man raiding force launched by submarine outside the mouth of the Gironde Estuary. From there, the team would paddle more than eighty miles during periods of limited visibility, emplace limpet mines on enemy shipping, and then evade by any means available, with the ultimate goal of returning to the United Kingdom. Operation Frankton validated the concept of kayak-borne raiding and directly influenced the development of British maritime special operations doctrine. During this same period, multiple parallel kayak development efforts were underway in the United Kingdom, refining folding designs and techniques that would later inform the Special Boat Service (SBS) and allied units.

Operation Frankton validated the concept of kayak-borne raiding and directly influenced the development of British maritime special operations doctrine. During this same period, multiple parallel kayak development efforts were underway in the United Kingdom, refining folding designs and techniques that would later inform the Special Boat Service (SBS) and allied units. Following the Second World War, kayaks remained in service with special operations forces in the United Kingdom, Europe, Africa, Asia and the United States. One of the most compelling post-war examples comes from the Rhodesian Bush War.

Following the Second World War, kayaks remained in service with special operations forces in the United Kingdom, Europe, Africa, Asia and the United States. One of the most compelling post-war examples comes from the Rhodesian Bush War. Kayaks enabled silent night movement, an extremely low visual and acoustic signature, and continuous repositioning without reliance on fixed bases, vehicles, or aircraft. This operation remains one of the most extreme examples of fieldcraft, endurance, and waterborne stealth in modern special operations history. Conceptually, it aligns more closely with Second World War SBS and Combined Operations Pilotage Party (COPP) missions than with later helicopter-centric SOF models.

Kayaks enabled silent night movement, an extremely low visual and acoustic signature, and continuous repositioning without reliance on fixed bases, vehicles, or aircraft. This operation remains one of the most extreme examples of fieldcraft, endurance, and waterborne stealth in modern special operations history. Conceptually, it aligns more closely with Second World War SBS and Combined Operations Pilotage Party (COPP) missions than with later helicopter-centric SOF models. Launching at night from offshore, the team paddled in extreme South Atlantic weather to avoid detection. Once ashore, the kayaks were cached and the patrol transitioned to foot movement to conduct reconnaissance of aircraft disposition, defensive routines, and terrain.

Launching at night from offshore, the team paddled in extreme South Atlantic weather to avoid detection. Once ashore, the kayaks were cached and the patrol transitioned to foot movement to conduct reconnaissance of aircraft disposition, defensive routines, and terrain. When I arrived at 5th Special Forces Group (Airborne), I sought assignment to an Underwater Operations Detachment commonly referred to as a dive team. Within three months, I had completed pre-scuba training and the Combat Diver Qualification Course (CDQC). My first deployment took me to Aqaba, Jordan, where kayak infiltration using Klepper folding kayaks was one of the methods we rehearsed.

When I arrived at 5th Special Forces Group (Airborne), I sought assignment to an Underwater Operations Detachment commonly referred to as a dive team. Within three months, I had completed pre-scuba training and the Combat Diver Qualification Course (CDQC). My first deployment took me to Aqaba, Jordan, where kayak infiltration using Klepper folding kayaks was one of the methods we rehearsed. Over the course of my career, we used kayaks for infiltration training, mothercraft launches, helocasting, and shore insertions. They were also used for long-distance paddling as physical training, team building, and on occasion as improvised fishing platforms. We rehearsed operational employment during a counter-narcotics mission that was ultimately cancelled due to circumstances outside our control.

Over the course of my career, we used kayaks for infiltration training, mothercraft launches, helocasting, and shore insertions. They were also used for long-distance paddling as physical training, team building, and on occasion as improvised fishing platforms. We rehearsed operational employment during a counter-narcotics mission that was ultimately cancelled due to circumstances outside our control. Over several months, I restored the frame to operational condition and sourced a new skin from Long Haul, which at the time held the U.S. repair contract for the original German Kleppers. Configured in a one-man expedition setup, the kayak is now used for physical training and personal stress relief a functional reminder of a demanding and enduring tradition.

Over several months, I restored the frame to operational condition and sourced a new skin from Long Haul, which at the time held the U.S. repair contract for the original German Kleppers. Configured in a one-man expedition setup, the kayak is now used for physical training and personal stress relief a functional reminder of a demanding and enduring tradition.