The Army Contracting Command – Aberdeen Proving Ground (ACC-APG), Natick Contracting Division, on behalf of US Army Combat Capabilities Development Command – Soldier Center (DEVCOM-SC), anticipates awarding a Cost-Plus-Fixed-Fee (CPFF) contract for the Ground Soldier Technology Workflow, Integration, and eXperience (GS-TWIX) effort.

The Ground Soldier Technology Workflow, Integration, and eXperience (GS-TWIX) effort develops ground Soldier-centric information technology across the operational spectrum of hardware, software, network, and data as well as integrates same to optimize the ground Soldier’s ability to shoot, move and communicate according to the Army Modernization Priorities. GS-TWIX will impact multiple DEVCOM Soldier Center efforts and collaborations including Sensored Soldier, Nett Warrior, Integrated Visual Augmentation System (IVAS), Soldier Integration Facility (SIF), Joint Program Executive Office (JPEO) Chemical Biological Radiological and Nuclear Defense (CBRND), OUSD Research and Engineering (R&E) 5G Tactical Applications for Small Units in Distributed Operations (5GTA-SUDO). These are detailed below:

Sensored Soldier

The goal of Sensored Soldier is to enhanced Multi Domain Operations (MDO) through mission information integration. This task has three sub-tasks that shall provide an interconnected tool suite of actionable decision tools by the end of FY25. First, the Leader Planning & Decision Tools sub-task shall guide Small Unit leaders in the maneuver planning for optimal Soldier physiological, equipment electrical power, network health, and protection using remote sensing drones. Second, the Soldier Equipment Sensing and Integration sub-task Shall provide Soldier Sub-system operational usage status to Small Unit leaders and provide equipment status sensing across the Squad workflow. Lastly, the Remote Sensing and Integration sub-task shall provide hardware, software, network, and data components that provide a Small Unit with a standoff capability to sense threats, maneuver, and communicate same to Small Unit leaders This sub-task shall 1) integrate remote sensing systems and sub-systems, 2) optimize user experience of remote squad sensing components, 3) optimize remote sensing MDO across the Small Unit workflow. Sensored Soldier tasks will transition to Nett Warrior, IVAS, or other Ground Soldier Systems Program of Record (PoR). Contractor shall provide DEVCOM – SC COR a technical report on Sensored Soldier activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Sensored Soldier activities in accordance with CDRL A005 on an annual basis.

Nett Warrior and Ground Soldier System

The contractor shall provide comprehensive and wide-ranging support to the PdM GSS for evolving, maturing, and maintaining NW V3.X system in the areas of software engineering, system engineering, cybersecurity, system architecture, and integration.

The Contractor, in conjunction with the PdM GSS NW SETA contractor, shall ensure the work has a migration path to the NW program record and/or NW Future Initiatives, if the capability needs time to mature. If the Contractor and PdM GSS NW SETA contractor have divergent views on how to ensure a successful transition to the NW program of record of these requirements or how work is divided between both parties, then the Contractor shall promptly notify PdM GSS (GSS Tech Director / NW Chief Engineer) so any required Government clarification / direction can be provided to both parties. The Contractor shall develop solutions that allows application developers to store and distribute information in their own data format. However, the contractor shall leverage server services already provided by the larger TAK ecosystem rather than developing their own server system. Contractor shall provide DEVCOM – SC COR a technical report on Nett Warrior and Ground Soldier System activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Nett Warrior and Ground Soldier System activities in accordance with CDRL A005 on an annual basis.

Ground Soldier Systems Integration

The contractor shall provide technical services for CCDC SC, IVAS, and other government agencies in areas of advanced concepts for information portrayal, sub-system integration, and data analytics: Similar to the IVAS-Soldier Integration Facility (SIF), CCDC SC Mission Information Team requires the development of information portrayal system that interacts with project objectives, project tasks, and both lab and field experimentation operations that includes Nett Warrior-based Soldier worn sensors, ATAK-platoon based sensors, and NW & ATAK web based sensors. Contractor shall provide DEVCOM – SC COR a technical report on Ground Soldier Systems Integration activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on Ground Soldier Systems Integration activities in accordance with CDRL A005 on an annual basis.

CBRND Integration with Ground Soldier Systems:

The Joint Program Executive Office for Chemical, Biological, Radiological, and Nuclear Defense (JPEO-CBRND) seeks to design, prototype, test, and document promising wearable capabilities integrated into a single system. The wearables system includes the following components: assistive automation capabilities; wearable, subcutaneous, and implantable devices; cyber secure and scalable wired and wireless architectures; and visualization and decision support tools. The contractor shall provide sub-systems that advance the human integration and current technology for lightweight, integrated wearable systems; Soldier integrated displays and body-worn systems that enhance the Soldier survivability, and situational awareness on the battlefield. Special interest areas include unique human systems integration of data and power systems, miniaturization, increased durability and reliability, and components having low power as well as new power solutions that meet Soldier-portable system requirements for survivability and situational understanding. Specific examples of body- worn system capabilities include: data devices, integrated electronic modules, inter- connections in fabrics, wearable battery technologies, combat identification, tactical engagement simulation capability, system voice control, State-of-the-Art unique interfaces, haptics, neuro-physiological, and physiological/medical sensors and data management, Soldier integration of individual/team weapon system sensors and controls. Contractor shall provide DEVCOM – SC COR a technical report on CBRND Integration with Ground Soldier System activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on CBRND Integration with Ground Soldier Systems in accordance with CDRL A005 on an annual basis.

5G Tactical Applications for Small Units in Distributed Operations (5GTA- SUDO)

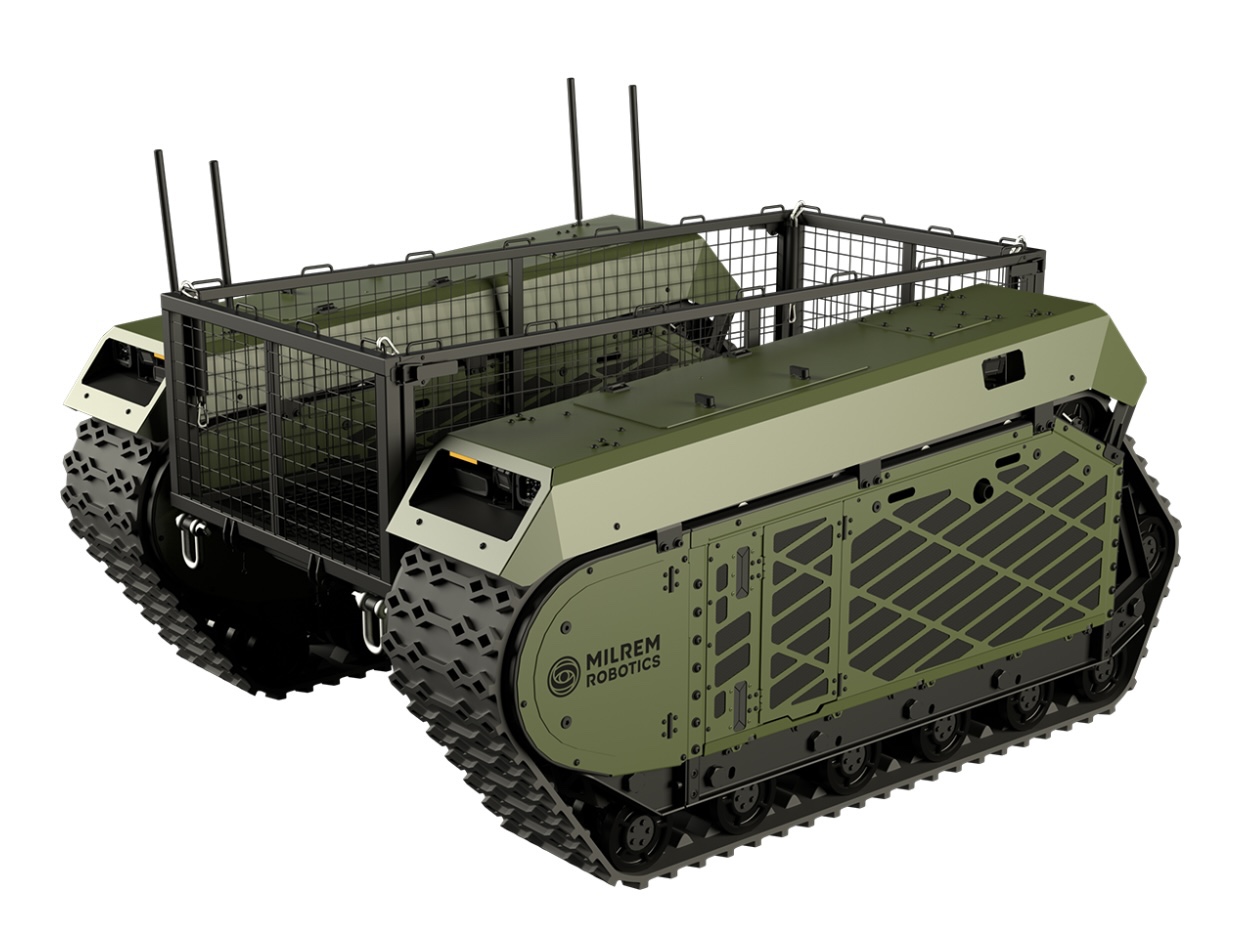

The goal of 5GTA-SUDO is to demonstrate the operational impact of a 5G bandwidth improvement to the Integrated Tactical Network (ITN). This task shall develop and demonstrate in an operationally relevant environment, at the Battalion & Company echelon level, multiple ground Soldier tactical applications. Tactical applications shall include 96 hour out load, sensitive site exploitation, sensor to shooter Full Motion Video (FMV) applications, edge device management, ITN multi-network/Primary, Alternative, Contingency, and Emergency (PACE)) router, image product distribution, robotic systems integration and other 5G-based applications. All applications shall be integrated with the software code base and hardware system for either Nett Warrior or IVAS. Contractor shall provide DEVCOM – SC COR a technical report on CBRND Integration with 5GTA-SUDO activities in accordance with CDRL A002 after a technology assessment/demonstration. Contractor shall also provide DEVCOM – SC COR an annual final report on 5GTA-SUDO in accordance with CDRL A005 on an annual basis.

GS-TWIX specifically seeks to design, develop, and analyze solutions associated with small unit ground Soldier systems and devices as they impact Soldier sub-systems integration, Soldier workflow, and Soldier experience. Historically, Small Unit systems were electronic in nature. Currently, Small Unit systems span the mechanical, electrical, software, network, and data engineering spectrum. Furthermore, the operational space for these solutions is also diverse covering warfighter functions spanning lethality, maneuver, communications, logistics, and protection.

The GS-TWIX effort in FY22 to FY26 will focus on equipment, systems, software, network, and data flow throughout the Soldier workflow as it relates to ground Soldier systems to address optimization in warfighter functions such as lethality, maneuver, communications, logistics, and protection.

The contract will consist of a one year base period and three (3) one year options. This acquisition is a 100% Small Business Set-Aside.

Proposals are due August 21, 2022 by 5:00PM EST (sic).

See the full details here.

?

?