NATICK, Mass. — The U.S. Army Combat Capabilities Development Command Soldier Center is working with Harvard University to research a wide range of technologies to enhance Soldier protection and performance. Soldier knowledge and input are playing a key role in the partnership.

“The collaboration between the CCDC Soldier Center and Harvard University will help identify and address capability gaps to better meet the needs of Soldiers and will help to get new critical capabilities into the hands of our Soldiers more quickly,” said Douglas Tamilio, director of the CCDC Soldier Center. “Research will also benefit immensely from the ingenuity of both organizations and from the added insight made possible by the involvement of former and current Soldiers throughout the research, development, engineering and testing process.”

The CCDC Soldier Center is dedicated to using science and technology to ensure America’s warfighters are optimized, protected, and lethal. CCDC SC supports all of the Army’s Modernization efforts, with the Soldier Lethality and Synthetic Training Environment Cross Functional Teams being the CCDC SC’s chief areas of focus. The center’s science and engineering expertise are combined with collaborations with industry, DOD, and academia to advance Soldier and squad performance.

The center supports the Army as it transforms from being adaptive to driving innovation to support a Multi-Domain Operations Capable Force of 2028 and a MDO Ready Force of 2035. CCDC SC is constantly working to strengthen Soldiers’ performance to increase readiness and support for warfighters who are organized, trained, and equipped for prompt and sustainable ground combat.

Some of the research being performed by Harvard and CCDC SC comes under a Cooperative Research and Development Agreement, or CRADA, between CCDC SC and Harvard’s John A. Paulson School of Engineering and Applied Sciences, or Harvard SEAS.

“The Master CRADA will provide a streamlined way for the organizations to collaborate in diverse areas of mutual interest and leverage each other’s expertise,” said Sheri Mennillo, CCDC SC’s technology transfer manager who helped develop the Master CRADA between Harvard and CCDC SC.

Dr. Kevin “Kit” Parker is the technical point of contact for Harvard for the CRADA. Parker is the Tarr

Family Professor of the Bioengineering and Applied Physics Disease Biophysics Group, Wyss Institute for Biologically-Inspired Engineering, at the John A. Paulson School of Engineering and Applied Sciences at Harvard University. Parker, a lieutenant colonel in the U.S. Army, is also a professor in the department of Chemical and Life Sciences at the United States Military Academy at West Point.

Parker and other scientists in his lab are working closely with the Soldier Center.

“Collaboration with academia is a critical means by which we at Soldier Center can ensure that we can provide truly innovative ways to increase Soldier lethality,” said Dr. Richard Green, director of the Soldier Protection and Survivability Directorate at the CCDC Soldier Center. “The Soldier Center is located near some of the premier academic research institutions in the world, and we regularly engage with local universities and universities that are farther away to help enable solutions that may not have been thought possible in the past. Through collaborations, such as our collaboration with Kit Parker’s lab at Harvard, we learn more about the art of the possible, and academia gets a better understanding of challenges the Army faces as we work to modernize for the future fight.”

“Academic collaborations, especially those with distinguished local universities such as Harvard, provide CCDC SC the opportunity to leverage cutting-edge expertise and facilities to augment our own R&D capabilities,” said Dr. Kathleen Swana, a researcher at CCDC SC. “CCDC SC, in return, provides valuable scientific and Soldier-centric expertise and testing capabilities to help drive the research forward. Dr. Kit Parker’s experience and technical prowess also provide a unique perspective on potential science and technology solutions for the Soldier, and I look forward to seeing the outcome of future collaborations with his lab.”

The spark for the initial idea for the partnership came about when Parker and Brian Wood, the G-8 budget officer at CCDC SC and formerly a lieutenant colonel in the U.S. Army Reserves, were attending a Pacific Operational Science and Technology meeting. Parker and Wood realized the many potential benefits of CCDC SC working with Harvard to advance technologies for the Soldier. Both men served in the same unit in the U.S. Army Reserve Sustainment Command Detachment 8.

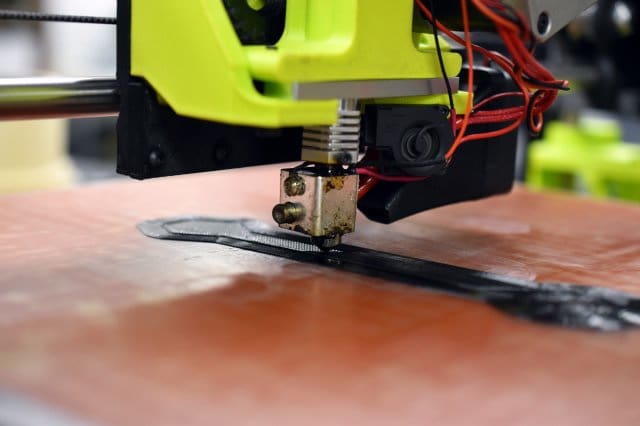

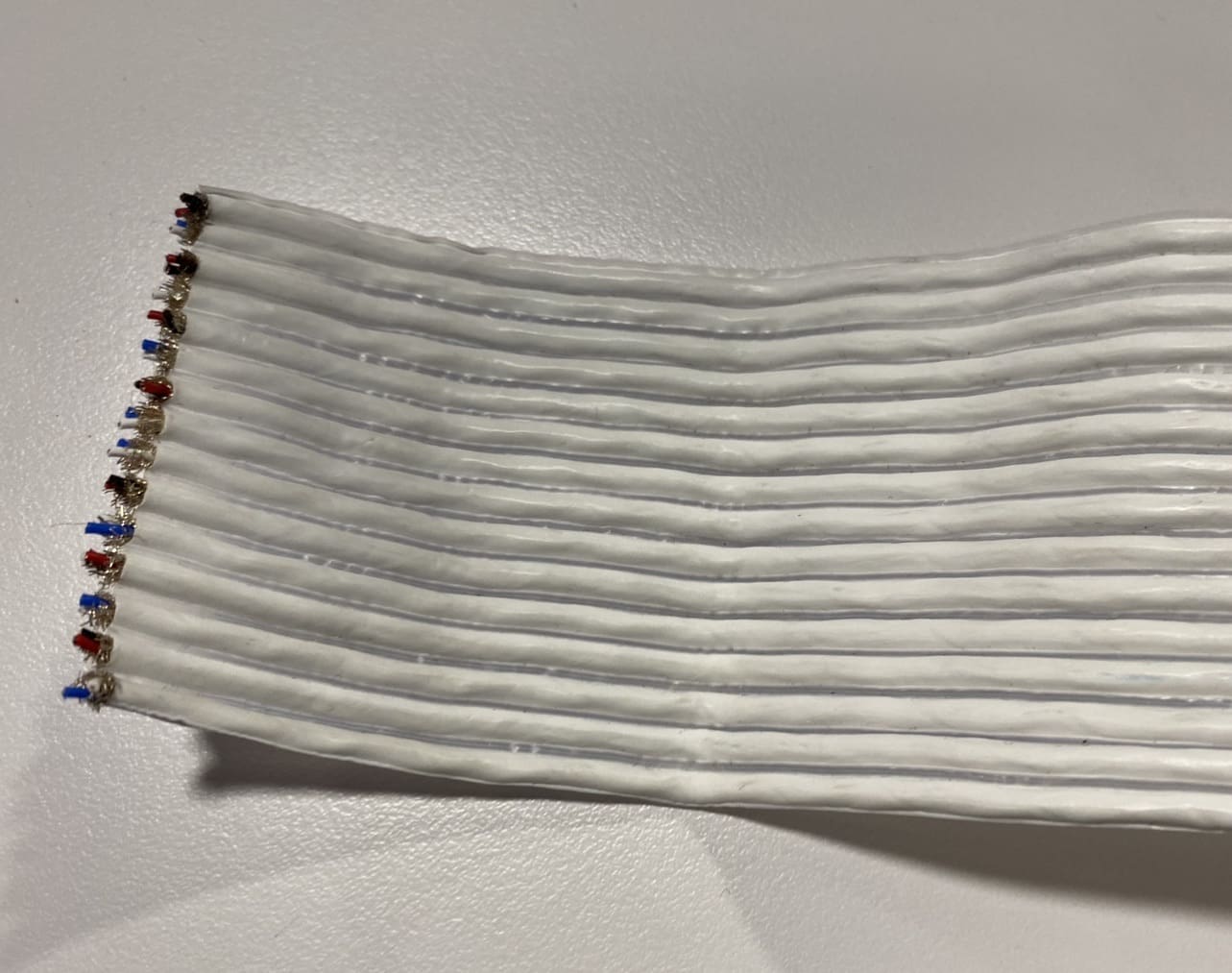

One of the projects that CCDC SC and Harvard University are working on together is the development and testing of ballistic protection nanofibers, which have the potential to be used to create lighter body armor.

Grant Gonzalez, one of Parker’s PhD students, invented the nanofibers.

“We are reimagining Kevlar fibers, attempting to make them stronger and tougher, by decreasing their diameter to change how the polymer inherently organizes and crystalizes,” said Gonzalez. “These fibers will decrease the weight the warfighter carriers without sacrificing protection.”

The Harvard inventor needed CCDC SC’s ballistics and testing expertise. Gonzalez, who has been the primary liaison between Parker’s laboratory and CCDC SC, has now graduated and is the first PhD student to be jointly mentored by people at CCDC SC and Harvard.

“The capabilities of the CCDC SC allow us to quantify the successes of our fibers from the perspective and needs of the warfighter,” said Gonzalez.

In addition to ballistic protection, Parker noted that the Kevlar nanofibers invented by Gonzalez have other potential uses.

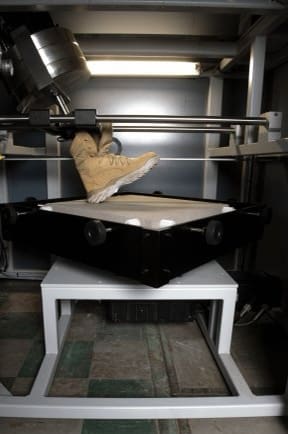

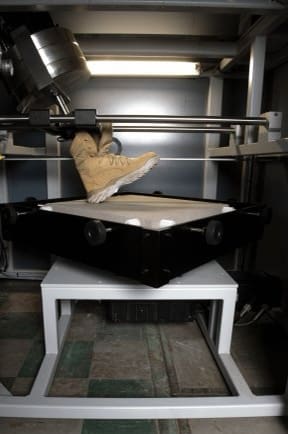

“We’re working with Natick’s boot lab to test Kevlar nanofibers on the bottom of combat boots and doing abrasion testing,” said Parker. “When working with the Kevlar and ballistics, we realized that there were some unique abrasive properties, helping Soldiers better navigate lava rock and terra firma. The Kevlar nanofibers also have flame-retardant properties. So, if you are an armored crew member or if you are on an aircraft, in both situations, you may need to worry about an onboard fire. The idea is that we may be able to put Kevlar nanofibers into your flight suit or crewmember suit to give you more flame retardancy.”

Gonzalez explained that the fibers may also have applications for emergency responders, police, and firemen.

“These fibers have potential applications in ballistic protection for police and puncture-resistant materials for emergency responders and firefighters,” said Gonzalez.

Former and current Soldiers are involved throughout research, development and testing process, providing all-important insight into identifying capability gaps to meet the needs of the warfighter.

“Army Reserve Soldiers bring a critical combination of expertise to the table — civilian education and professional experience coupled with military experience and associated professional relationships from both sides,” said Wood. “Having current and former Soldiers involved in S&T brings expertise, experience and the passion to follow the effort to completion. Further, these Soldiers may personally benefit from the S&T developments and new capabilities in an operational environment. Through Soldiers’ knowledge and operational experience, they bring critical insight as to what is needed and if/how the new equipment will be used.”

Parker served several combat tours in Afghanistan and has first-hand knowledge of issues and capability gaps faced by Soldiers on the battlefield. Parker’s lab at Harvard includes many military veterans, including veterans who did tours of duty in Iraq and Afghanistan, as well as tours in Africa and the Philippines.

“So these are folks with first-hand battlefield experience,” said Parker. “This is unprecedented. There are multiple layers of expert input going into the science.”

West Point cadets also participate in Parker’s lab at Harvard. CCDC SC works collaboratively with West Point cadets as well.

“I want cadets to understand the role of science and technology in providing for the force,” said Parker. “It’s important to get users involved in design processes very early on. In addition to Soldier research, the idea is that we are training tech-savvy leaders for the next generation of Army combat leaders, and we are training the next generation of civilian scientists and engineers to support national security.”

Parker pointed out that there is great potential for Soldiers to work in labs after uniformed service. He noted that this experience builds on, and exploits, their value to the nation and supports the model of Soldier for Life.

“I have a bunch of military veterans, including Army, working in my lab,” said Parker. “Taking these junior enlisted and junior NCOs and bringing their subject matter expertise, technical knowledge, and applications orientation to the basic science lab is extremely unusual and points to what I call ‘Soldier innovation.’ Junior enlisted and NCO corps expertise are one of the greatest untapped resources that our defense research complex needs to access.”

Parker said he greatly admires the brain power available at CCDC SC. He is eager to expand his research ties throughout CCDC SC and is eager to establish a working relationship with the Combat Feeding Directorate in particular.

“Soldiers have unique dietary needs,” said Parker. “I think people don’t realize that when you sit down to eat an MRE (Meal, Ready to Eat), that’s a scientific and technology parade.”

Both Wood and Parker are dedicated to serving the Soldier and believe the CRADA will lead to even more collaborative efforts in the future.

“Since the CRADA reaches into the entire School of Engineering and Applied Sciences, we anticipate that this agreement could lead to break through developments in multiple technical areas,” said Wood.

“I want to be able to say that the Soldier in the field is better off because of something we did in the lab,” said Parker. “We want to make a major contribution to the Army’s future.”

By Jane Benson, CCDC SC