The 2017 Ravens Challenge EOD exercises were funded by the Army and led by the Bureau of Alcohol, Tobacco, Firearms and Explosives, with support from the FBI, the Defense Department, the Transportation Security Administration and state and local public safety agencies throughout the country.

This year’s exercises took place at Camp Pendleton in August, Pinal Airpark in Marana, Arizona, in March; Muscatatuck Urban Training Center, North Vernon, Indiana, in April; Camp Dawson, Kingwood, West Virginia, in May; and Camp Shelby, Mississippi, in June.

A DoD News article by Shannon Collins describes the event:

Throughout the week, the combined teams went through training scenarios, or lanes. One such scenario was a hostage situation, where a hostage in a stairwell had a bomb strapped to his body while other hostages were upstairs and there was a body booby-trapped on the ground floor. Teams also dealt with locating hidden devices, an aircraft with a device in the cabin or baggage area, improvised mortars located on rooftops and in vehicles, a cabin with booby traps and a suspicious package in a hospital.

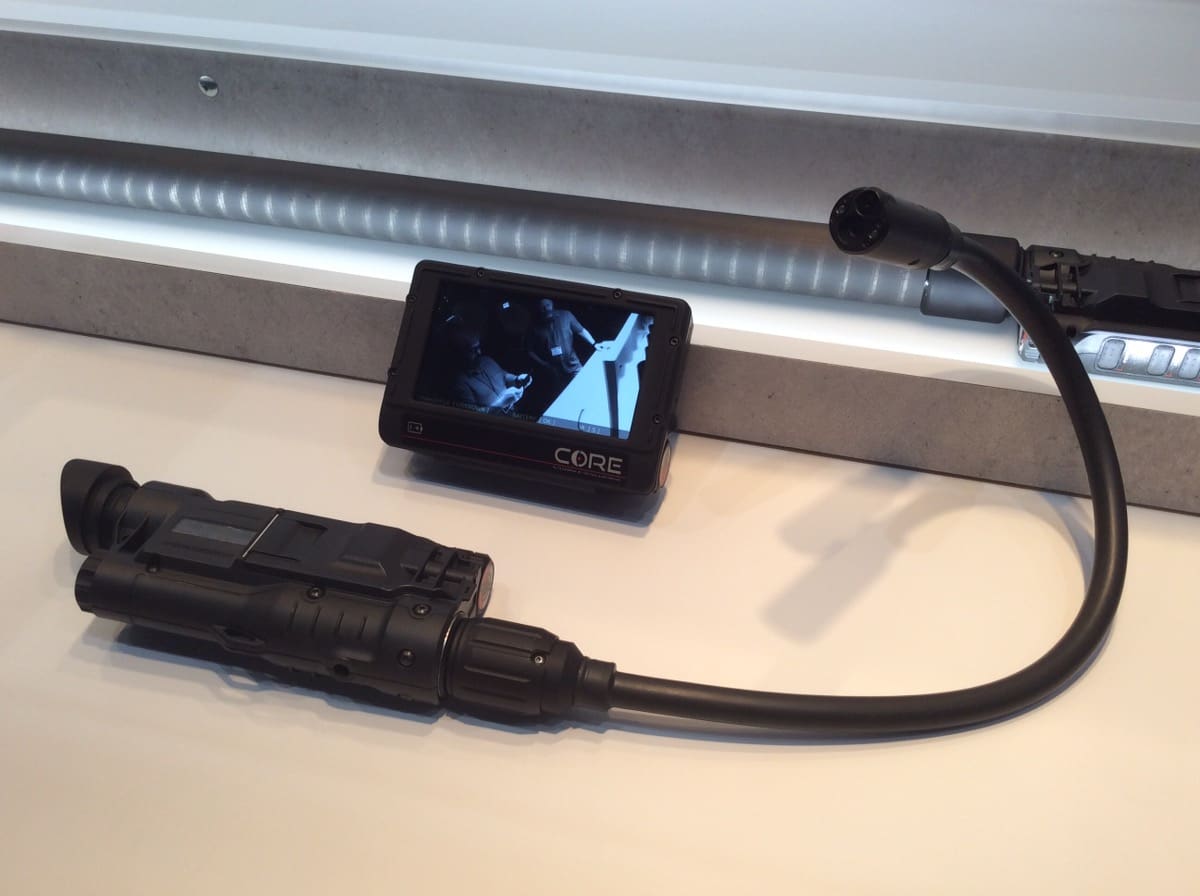

Training was under realistic conditions, and included a no-light and low-light environment, where technicians had to use night-vision goggles while entering a village and disarming devices through the goggles or with the naked eye.

“The no-light, low-light was my favorite. because it’s the most challenging thing an EOD tech can do — walk through something you can barely see,” said Army Spc. Seth Hamilton, an EOD technician from Fort Bliss, Texas. “You’re hot, you’re tired, they’ve booby-trapped an entire warehouse; so you’re going through in the middle of the dark, just trying to get through without dying. It had the best training value.”

Lanes were also focused on responding to the developing tactics of terrorists, such as the use of booby-trapped unmanned aerial systems.

“The UAS seems to be the emerging threat, … because of the widespread availability of unmanned systems. It’s exciting for us to say, ‘Hey, this is a new emerging threat.’ We’re going to be the people figuring out how to address it and come up with the [tactics, techniques and procedures] to become more proactive,” said Marine Corps Gunnery Sgt. Brian Murphy, an EOD technician here.

Intelligence analyst B. Joshua Bauer discusses terrorists’ use of commercially available unmanned aircraft with U.S. and Belgian explosive ordnance disposal teams during the Raven’s Challenge exercise at Camp Pendleton, Calif., Aug. 1, 2017. DoD photo by EJ Hersom

Intelligence analyst B. Joshua Bauer discusses terrorists’ use of commercially available unmanned aircraft with U.S. and Belgian explosive ordnance disposal teams during the Raven’s Challenge exercise at Camp Pendleton, Calif., Aug. 1, 2017. DoD photo by EJ Hersom

“The new [unmanned aerial vehicle] threat, we’re the first people in our company to get that knowledge and run that lane, and we can’t do that at our home station,” said Army Staff Sgt. Sean Mattes, an EOD bomb technician from Fort Bliss. “So now we can go back and help educate those guys and tell them what we’ve learned but until they come to something like this, they’ll never get that training. You really broaden your skills with the site layout and coordination. You’ve got to get every tool out and use it, and that’s what I like doing.”

“The teams who went up against the UAVs for the first time had no procedures to use,” said Col. David Schmitt, chief of the Army’s adaptive counter-IED/EOD solutions division. “There was no logic tree to follow to get to the right solution, so they were working that out inside their heads, but if we do it right, then the issues will be captured in the after-action report, the review will go back into the process, so next year, they will have a logic train for this scenario.”

Schmitt said Raven’s Challenge is one of the largest DoD EOD counter-IED interoperability training exercises in the world. “Continuing to do this kind of training provides incredible benefits for the individual participants, but also for the services and the bigger institutions that sends the participants, because it feeds into the after-action reviews,” he said. “These feed into the institutional processes that drive what equipment we buy, what training we do in our institutions. It drives a lot of change in the Army, and, I would imagine, elsewhere.”