Who?

Eagle Eye Innovations (EEI) was founded in 2013 by Sion Roberts, an ex-sensor operator for the MQ-9 Reaper in the Royal Air Force (RAF), delivering Remotely Piloted Aircraft Systems (RPAS) training. EEI quickly became a Civil Aviation Authority (CAA) Recognised Assessment Entities (RAE) delivering accredited training services to the UK market, and is now one of the longest running RAEs.

The company has since grown significantly over the last 5 years, including increasing its ownership and Directorship with key experience to help grow the company beyond its roots. In addition, the team is now 35 strong, with plans to grow further in Q4 2023, and boasts over 550 years of military experience and over 50,000hrs instructing and operating Intelligence, Surveillance, and Reconnaissance (ISR) platforms across the Air, Land, and Maritime domains, including exquisite platforms such as the RAFs MQ-9 Reaper.

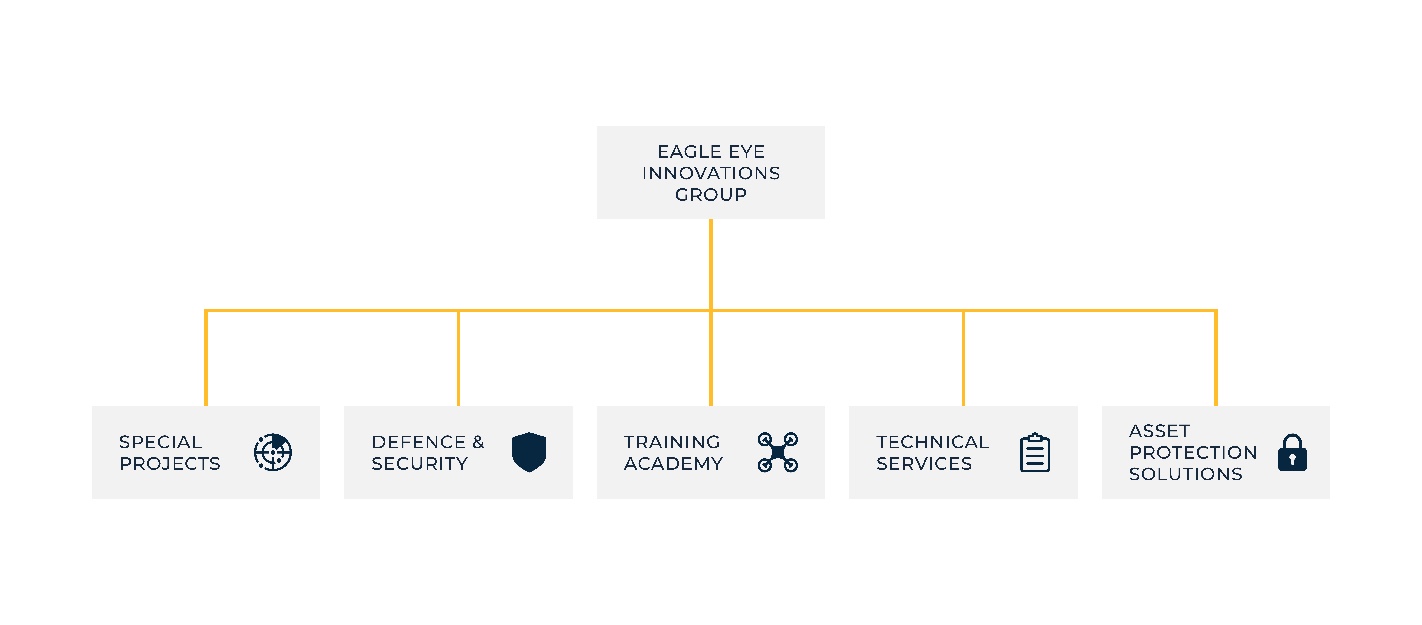

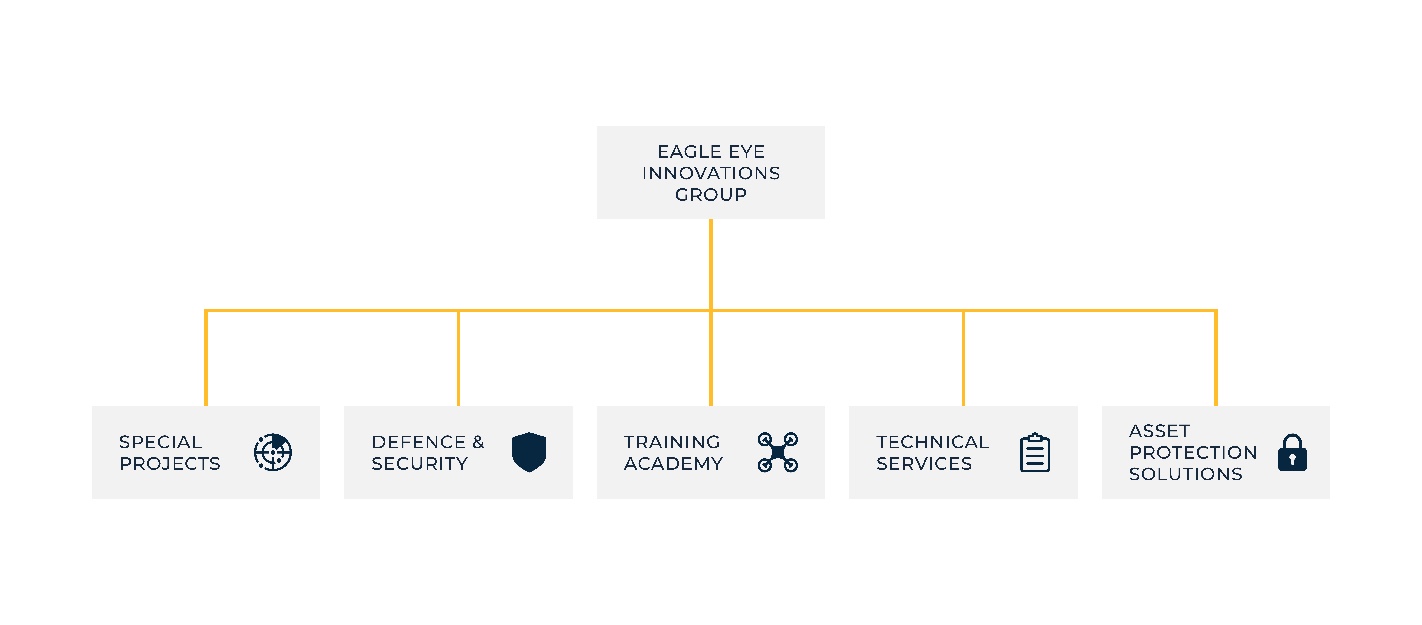

Currently, EEI operates across 5 core departments (see below); Training Academy, Technical Services, Defence & Security, Special Projects, and EEI Asset Protection Solutions (EEI-APS), with a key to success being that they do not make RPAS / drones. Rather, EEI specialises in supporting customers through requirement definition, procurement support, integration, training, and operational services; ensuring the customer procures the correct system for their needs and realises its full capability.

What?

Being system agnostic, EEI provides services across all classes of RPAS, regardless of size, weight, and complexity, to the commercial and defence sectors globally. The trusted, equipment independent nature of the organisation has grown a position of trust acting as the ‘customer friend’ in a rapidly developing technology space, and has become a ‘one-stop-shop’ for RPAS support solutions for many commercial and defence customers globally.

EEIs vision is to enable safe RPAS operations for the world, leveraging high-end, ex-military expertise to assist customers from all walks of life to access and operate ground breaking RPAS technology to enhance their services or operations, safely.

Key to EEIs capability is being able to work closely with customers to understand ‘why’ or ‘how’ RPAS/drones can be of benefit across any industry, developing key equipment requirements, putting output before equipment. This model enables a more informed procurement decision and invariably mitigates spiralling program costs compared to less informed equipment procurement decisions.

Beyond requirement analysis and procurement support, EEIs industry leading training analysis, development, build and delivery services in the RPAS sector are at the heart of the organisations vision. Regularly, customers across commercial and defence sectors engage with EEI having experienced inferior training elsewhere due to the quality of product, delivery, and after sales support. Indeed, EEI services go well beyond training, supporting customers with integration services, Test and Evaluation (T&E) of new and novel technology, operational support through direct support to customer operations or delivering operations on behalf of the customer, and Research & Development (R&D) to help identify emerging gaps and opportunities for the technology within the global marketplace. A new and novel application of this technology is its use in lifesaving off the UK shores. EEI has teamed with the Royal Life Saving Society (RLSS) to ensure our coastal lifeguards are trained to utilise RPAS/drones to increase the likelihood of survival for those individuals that find themselves in distress at sea.

One of the newest areas of EEI is the Special Projects department. This team offers partners a discreet operationally focussed framework with appropriate security safeguards. Special projects are geared to understand and support the RPAS needs of other private and public entities in complex environments that fall outside of our traditional offerings wherever their operations occur around the world.

When?

The EEI journey began with the conception of the company on the 31st of July 2013, delivering groundbreaking monthly RPAS training courses to the UK market at the beginning of 2014.

In late 2018, Alex Kasperczyk (Director of Business Development) and Dominic Smith (Director of Operations) left the RAF to invest into EEI, which enabled the next stage of growth for the organisation and expanded the scope of its services into the defence sector. EEI now delivers its suite of services to all three Services and a large percentage of UK Emergency Services.

In 2021, EEI teamed with Jordan Crowns’ Crown Consulting organisation to develop a roadmap to delivering assured and effective security enhanced with the use of RPAS. This resulted in Crown Consulting being absorbed into EEI to create EEI Asset Protection Solutions (EEI-APS) that now delivers domestic security to high profile private clients and large-scale events, international crisis and risk management services to a variety of clients, and organic support to EEI to enable expeditionary RPAS services into complex or hostile environments.

In September 2023, EEI will be launching EEI Europe in Malta at the Maltese Air Show. Building on successes and growth over the last decade, this strategically important step will give access to new markets and customers around Europe, and further afield, as the organisations continues to drive towards its vision.

Where?

Headquartered in Lincoln, UK, EEI has supported clients as far a field as Australia, Asia, Africa, and Eastern Europe. Launching EEI Europe from Malta will enable a more global reach for the organisation, give the ability to work closely with the European Union Aviation Safety Agency (EASA) following BREXIT, and provide a launch pad for support to customers beyond Europe.

EEI has several pre-established flight sites across the UK to support customer training wherever they may be, with the intent to grow this overseas with the establishment of EEI Europe. The ‘jewel in the crown’ being the EEI Centre of Excellence (CoE); a private 300m grass airstrip less then 10mins from the EEI HQ in Lincoln.

Why?

As RPAS/drone technology becomes more accessible for all customers globally, the use cases become more complex, and the technology itself accelerates into new, untested capability areas daily, the importance of safe RPAS operations becomes increasingly critical to ensure its succeeds and thrives alongside traditional aviation.

Recent examples in the UK have seen commercial RPAS/drone operators having received legal action against them for using their technology in an unsafe manner or in a restricted environment. To mitigate this, education is key and EEI aim to be at the heart of this now and into the future.

In an ever-growing and saturated market such as the RPAS equipment industry, it’s important for an organisation like EEI can independently support clients with the development of appropriate, efficient, and safe solutions that provide operational and economic advantage.

For more information visit our website www.eeinnovationsltd.com or email info@eeinnovationsltd.com