Agilite just launched the new WIDE admin pouch which is optimized for MOLLE second layers to give extra low profile real estate.

See all the features here:

agilitegear.com/products/wide-admin-pouch

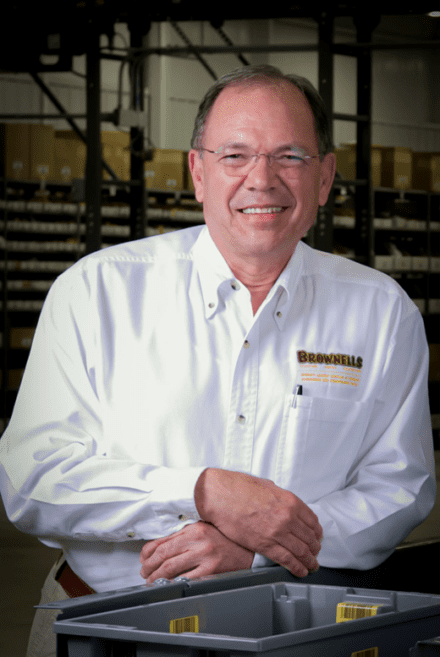

GRINNELL, Iowa (June 18, 2025) – Brownells sadly announces the death of long-time family patriarch Frank Brownell, who successively held the positions of President, CEO, and Chairman of the Board at Brownells.

Frank passed away in Grinnell, Iowa on June 18, 2025, after a lengthy illness. He was six days shy of his 86th birthday.

For nearly six decades, Frank’s passion, vision, and generosity shaped not only Brownells, but the entire firearms community. Friends and customers alike remember him greeting “long lines of friends” at SHOT Show and the NRA Annual Meetings, championing gunsmithing, and driving industry innovation.

“Frank was the kind of person who made you better just by being around him.” Pete Brownell, CEO of Brownells and Frank’s son.

A Life of Service and Contribution

Born June 24, 1939, in Montezuma, Iowa, the second child and only son of Brownells founder Bob and his wife Lois, Frank grew up in Iowa and became involved in both the family business and the American gun industry at an early age. Frank graduated magna-cum-laude with a degree in Advertising from the University of Iowa in 1961 before serving aboard the USS Caliente (AO-53) as a U.S. Navy reservist.

In 1965, he joined Brownells full-time, laying out Big Book Catalog #18, and soon helped publish the first Gunsmith Kinks book in 1969 under the name F. Brownell and Son.

Frank became President in 1983, CEO in 2007, and Chairman of the Board in 2012, guiding Brownells for more than 40 years.

From marketing the now-iconic Latigo Sling at the 1964 NRA convention to elevating gunsmithing as a respected profession, his influence can be seen in countless shops, ranges, and workbenches across America.

A Legacy of Character

Beyond titles and accolades, Frank was cherished for his kindness, integrity, and infectious enthusiasm. Frank Brownell was a Navy veteran, a business leader, and a stalwart supporter of our unique American rights guaranteed by the 2nd Amendment.

An industry innovator, he helped establish Brownells as a nationwide legacy retailer in the gunsmithing, gun parts, and firearms space. He helped advance the best model for working with and developing endemic industry media. He advocated for elevating gunsmithing to a respected profession and created new ways to support and develop the growth of gunsmithing, gun ownership, and gun culture.

A Life Remembered

Frank is survived by his three sons, Bob, Pete, and Matt Brownell, and their families. Service details will be shared once arrangements are finalized.

Friends, colleagues, and customers are encouraged to honor Frank by sharing memories, supporting aspiring gunsmiths, or simply spending time at the bench, just as he loved to do.

In modern defense ecosystems, coated fabrics have long played a foundational role. Traditionally employed for protective tents, uniforms, vehicle covers, and chemical-resistant apparel, these fabrics are typically enhanced with coatings such as polyurethane, PVC, or silicone to improve resistance to fire, water, and chemicals. However, recent advancements are redefining this segment, transforming coated fabrics into intelligent, adaptive components of the military supply chain. This shift aligns with the broader transition toward digital warfare and performance-optimized soldier systems, where smart coatings are poised to revolutionize protection and functionality. These changes are accelerating the evolution of the Coated Fabrics for Defense Market into a hub of innovation and strategic value.

Defining Smart Coated Fabrics

What makes a coated fabric “smart” isn’t its base material but the functional capability of its coating. This could include embedded sensors, nanomaterials, or reactive compounds designed to detect, communicate, or adapt. These functionalities create fabrics that can actively participate in defense operations, rather than passively endure them.

Examples include:

– Thermochromic coatings that change color based on temperature

– Electroconductive coatings that relay biometric data

– Fluorescent detection for exposure to biological or chemical threats

– Nanostructured coatings with self-healing capabilities

These innovations are often developed using advanced materials such as graphene, metal-organic frameworks (MOFs), and phase-change polymers, which are increasingly influencing the Coated Fabrics for Defense Market outlook.

Make Informed Decisions – Access Your Sample Report Instantly! www.futuremarketinsights.com/reports/sample/rep-gb-6762

Real-World Applications in Defense

Smart coated fabrics are becoming instrumental across both soldier systems and field infrastructure. For instance, wearable fabrics with biometric sensors are now enabling commanders to monitor soldier vitals in real time. These systems can detect fatigue, dehydration, or stress and relay that data via wireless communication systems, improving situational awareness and medical response.

Meanwhile, infrastructure applications are expanding as well. Lightweight, heat-reflective tents coated with adaptive materials now provide better thermal insulation. EMI (electromagnetic interference) shielding fabrics protect mobile communication units from signal disruption in electronic warfare scenarios. These are not experimental—they’re being implemented in NATO field units and combat support facilities, further boosting the potential of the Coated Fabrics for Defense Market.

Use Case Highlights

Below are real-world implementations showcasing the potential of smart coated fabrics in defense:

– USA Army’s Warrior Web Program: Developing sensor-embedded suits that detect joint strain and prevent injury.

– Israeli Defense Forces: Utilizing nanotech coatings on tactical vests for chemical agent detection.

– Indian OFB (Ordnance Factories Board): Collaborating on smart uniforms that adjust thermal insulation in desert and Himalayan conditions.

– European Defense Agency Projects: Supporting camo coatings that adapt to surrounding infrared and visible light conditions.

Browse the Complete Report! www.futuremarketinsights.com/reports/coated-fabrics-defense-market

Market Drivers Fueling Smart Fabric Demand

Multiple forces are converging to elevate the role of smart-coated fabrics in defense strategies. The most notable include increased geopolitical tensions, a rise in chemical and biological warfare threats, and the broader movement toward digital integration in military operations. Defense procurement bodies are demanding multi-functional materials that reduce the logistical burden and enhance survivability in complex environments.

Additionally, with greater attention on soldier comfort and long-term injury prevention, wearable technologies are now embedded into fabric-based systems rather than external devices. The focus is on low-weight, durable, and integrated protection—qualities that smart coatings are uniquely positioned to deliver. These attributes are shaping the future of the Coated Fabrics for Defense Market as defense agencies seek value-added textiles.

Obstacles to Mass Adoption

Despite strong R&D momentum, smart coated fabrics face scalability and adoption challenges. Foremost among these is cost. Nanomaterial-infused coatings and embedded sensor grids significantly raise the cost per unit, making procurement difficult for lower-budget defense forces.

Purity and reliability are also concerns. Some coated fabrics face contamination or degradation in extreme climates, limiting their longevity. Additionally, power supply integration remains an unsolved issue for wearable electronics, particularly in remote or power-scarce combat zones.

Another barrier is standardization. There is currently no unified framework across NATO, BRICS, or other global blocs that governs performance benchmarks for smart-coated defense textiles. As such, cross-border procurement and integration remain complex and fragmented—an ongoing challenge for global expansion within the Coated Fabrics for Defense Market.

Regional Trends and Competitive Landscape

North America and Western Europe continue to dominate smart fabric innovation due to strong defense R&D funding and established military-industrial ecosystems. However, Asia-Pacific nations are rapidly closing the gap. China, South Korea, and India have launched targeted initiatives to localize advanced textile manufacturing for their armed forces, often supported by public-private R&D partnerships.

Textiles, Fabrics, Yarn & Fibres Industry Analysis: www.futuremarketinsights.com/industry-analysis/textiles-fabrics-yarn-and-fibres

The Middle East, with its extreme environments and growing defense budgets, is also emerging as a niche consumer for adaptive thermal fabrics and chemical-protective coatings. These trends are creating a multi-regional competitive ecosystem in the Coated Fabrics for Defense Market.

The Future of Coated Fabrics in Defense

As combat scenarios grow more asymmetric and technologically complex, coated fabrics will serve increasingly as both shield and sensor. The integration of AI for data interpretation, wearable computing, and real-time health diagnostics into fabrics is set to blur the line between clothing and equipment.

This transition won’t just change procurement contracts—it will redefine defense strategies around survivability, mobility, and intelligence. The Coated Fabrics for Defense Market is no longer confined to passive materials; it is evolving into a sector that delivers smart, data-ready, and mission-critical solutions for the battlefield of tomorrow.

Related Reports:

Industrial Pipe Insulation Materials Market: www.futuremarketinsights.com/reports/industrial-pipe-insulation-materials-market

Pharma Grade Sodium Bicarbonate Market: www.futuremarketinsights.com/reports/pharma-grade-sodium-bicarbonate-market

Cold Rolling Oils/Lubricants Market: www.futuremarketinsights.com/reports/cold-rolling-oils-lubricants-market

Hydrofluoric Acid Market: www.futuremarketinsights.com/reports/hydrofluoric-acid-market

Natural Cinnamic Aldehyde Market: www.futuremarketinsights.com/reports/natural-cinnamic-aldehyde-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

NEWINGTON, N.H., (June 19, 2025) – SIG SAUER, industry leading manufacturer of cutting-edge firearms, optics, and ammunition announces its latest optic innovation, the ROMEO8T-AMR and JULIET3T-AMR System, featuring SIG SAUER’S all-new Automatic Modified Reticle (AMR) technology.

“Our products are engineered to exceed the demands of elite warfighters around the world and our latest optic innovation does just that,” said Andy York, President, Electro-Optics. “Our elite end-users expect innovative, battle-tested products like our new ROMEO8T-AMR and JULIET3T-AMR System. These innovative optics provides shooters the SIG SAUER precision they need in dynamic environments.”

Inspired by SIG SAUER’s original ROMEO8T red dot, the ROMEO8T-AMR™ is a powerhouse optic pushing the technological envelope while reducing overall size and weight by over 30% compared to traditional holographic sights.

Developed alongside the all-new JULIET3T-AMR™ micro magnifier, the ROMEO8T-AMR leverages SIG SAUER’s revolutionary Automatic Modified Reticle™ technology to instantly transition between user-selectable reticle configurations as the magnifier is engaged or disengaged. The speed and versatility of the patented AMR™ system allows shooters to maintain absolute precision while quickly transitioning between reticle configurations best suited for close-range engagements and mid-range engagements.

Despite its compact build, the ROMEO8T-AMR boasts a massive 40MM objective lens for unrivaled situational awareness, while the high-performance coatings and lens system deliver remarkable performance under night vision.

Engineered to exceed the demands of elite warfighters around the world, the ROMEO8T-AMR and JULIET3T-AMR system meet MIL-810-STD protocol, are IPX8 waterproof and fogproof, and fully covered by SIG SAUER’s Infinite Guarantee™.

Product Details:

AMR™ – Automatic Modified Reticle (Patented)

Massive 40MM High-Performance and Multi-Coated Lens

30% Smaller than Competitive Holographic Sights

Dedicated NV Override Control

50,000 Hour Runtime On CR123 Utilizing MOTAC™

MIL-810-STD Durability

IPX8 Waterproof and Fogproof Certified

Assembled in Oregon, USA

The ROMEO8T-AMR and JULIET3T-AMR system was previewed at SIG NEXT 2025, a one-of-a-kind innovation showcase and immersive product and brand experience that can only come from SIG SAUER, the defense contractor of the future.

The ROMEO8T-AMR and JULIET3T-AMR system is now shipping and available at retailers nationwide. To learn more, visit sigsauer.com.

WILL ROGERS AIR NATIONAL GUARD BASE, Okla. —

The 137th Special Operations Wing held a welcome ceremony for the arrival of OA-1K Skyraider II aircraft to Will Rogers Air National Guard Base, June 07, 2025, Oklahoma City.

The Skyraider II is a cost-effective, versatile aircraft that will provide essential support for operations outlined in the 2025 Interim National Defense Strategy. WRANGB now serves as the home for the Skyraider II’s formal training unit under the 492nd Special Operations Wing.

“Seamless integration with total force partners has been the standard for the 137th Special Operations Wing,” said Col. Shelby Dreyer. “We are continuing that legacy as we usher in this Total Force Initiative alongside the 492nd Special Operations Wing to train for the multi-capable mission of the OA-1K Skyraider II.”

The ceremony introduced the Skyraiders II’s capabilities and mission set to 137 SOW Citizen Airmen. The Skyraider II is a new cost-effective crewed aircraft that supports geographically isolated Special Operations personnel in austere locations.

“The 137th SOW continues to build and preserve a force where human performance is our critical advantage – leaning into the advanced training and resource management that supports our preparedness in every environment, against every adversary,” said Dreyer. “With the partnership of our wings, this is the right time. Oklahoma is the right place.”

By SSgt Nicholas Swift

137th Special Operations Wing

This is a little bit of an unexpected treat. I was able to fire the Royal Marines L143A2 rifle which were purchased a couple of years for the Future Commando Force operational concept under Project HAY, but not announced until March of this year.

It’s a SIG MCX carbine features 5.56 NATO 12.5″ barrel, but there’s also a 300 BLK variant also in service.

As you can see in the photo released by the Royal Marines, this is how it is equipped for maritime operations, with optic and magnifier and suppressor.