This is the first in a series of articles covering WL Gore’s various technologies and their military applications. While we are all familiar with the popular GORE-TEX brand, many do not know that WL Gore has worked extensively with the military since the mid-1980s to develop specific fabrics for various purposes. In this article we will cover GORE-TEX fabrics used in the Flame Resistant Environmental Ensemble issued to US Army Armored Vehicle and Air Crews.

FREE is a true head-to-toe FR environmental clothing system. It incorporates numerous levels consisting of garments that can be used alone or together, along with FR improved Combat Vehicle Coveralls and Army Aircrew Combat Uniform to face virtually any extreme weather conditions.

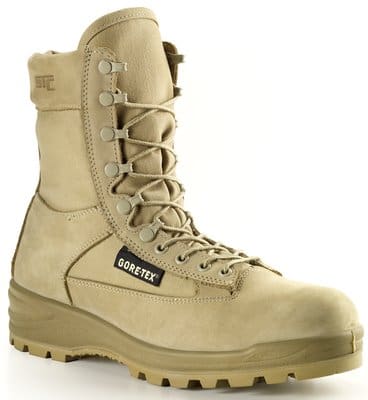

GORE-TEX membranes are used in the Extreme Weather Outer Layer Parka and Trouser. It is a breathable 3-layer laminate that combines DuPont’s Nomex fiber face material with a GORE-TEX ePTFE membrane and a Nomex mesh inner fabric. It is printed in the US Army’s Universal Camouflage Pattern (UCP) or the Operation Enduring Freedom Camouflage Pattern (OCP) for operations in Afghanistan where it has been used extensievly. EWOL is the most external layer in the clothing system and combines wet and extreme cold weather protection. It incorporates a fleece liner in order to help regulate temperature. Due to its intended use in vehicles and aircraft is a little bulky for use by dismounted troops.

Based on the success of FREE, ADS has developed Dismounted FREE so that all troops will have access to an FR environmental clothing system. FREE is currently only issued to armored vehicle and air crewmen but the threats affect everyone on an aircraft or in a vehicle. With Afghanistan’s extreme environment, troops are exposed to multiple threats; enemy fire, IEDs and weather. DFREE helps mitigate the effects of two of those.

Due to the difference in mission between mounted and dismounted troops, DFREE more closely mirrors Gen III ECWCS. This accomplishes two things. First, it means that the overall system is slightly lighter because ground troops have to carry it. Additionally, troops already understand how to use the system so new equipment training is kept to a minimum.

Keeping this philosophy in mind, the GORE-TEX level in DFREE more closely mirrors Gen III’s Level 6 than the EWOL level found in the mounted FREE. Rather than a 3-layer laminate DFREE’s Extreme Wet/Cold Weather Level (EW/CW) incorporates a 2-layer fabric with the ePTFE membrane paired with a durable nylon face fabric coated with WL Gore’s Pyrad FR treatment. Look for in-depth coverage of Pyrad here on SSD soon.

The entire FREE system, including the Dismounted variant, is available through ADS Inc – www.ADSinc.com/solutions/clothing-programs/free