RESEARCH TRIANGLE PARK, N.C. — An Army-funded project developed a self-healing material patterned after squid ring teeth protein. The biodegradable biosynthetic polymer could be used to repair materials that are under continual repetitive movement such as robotic machines, prosthetic legs, ventilators and personal protective equipment like hazmat suits.

“Materials that undergo continual repetitive motion often develop tiny tears and cracks that can expand, leading to catastrophic failure,” said Dr. Stephanie McElhinny, biochemistry program manager, Army Research Office, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory. “With a self-healing bio-based synthetic material, any sites of damage that emerge can be repaired, extending the lifetime of the system or device.”

The research at Penn State University and Max Planck Institute for Intelligent Systems, Stuttgart, Germany, funded in by part by ARO, and published in Nature Materials produced high-strength synthetic proteins that mimic those found in nature. The researchers surveyed large libraries of novel proteins created by assembling repetitive sequences from the squid ring teeth protein in different configurations.

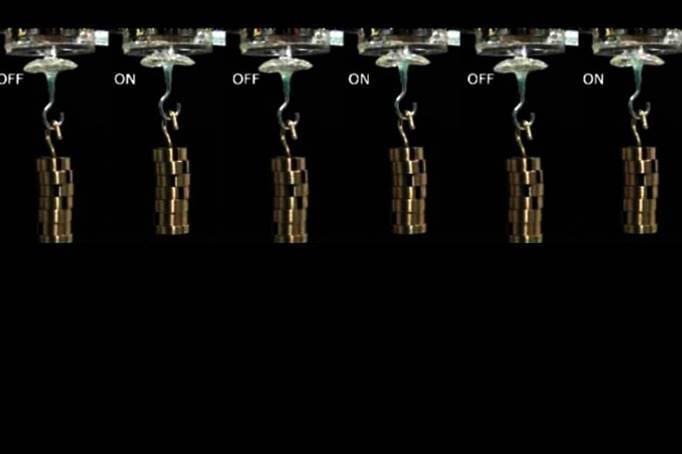

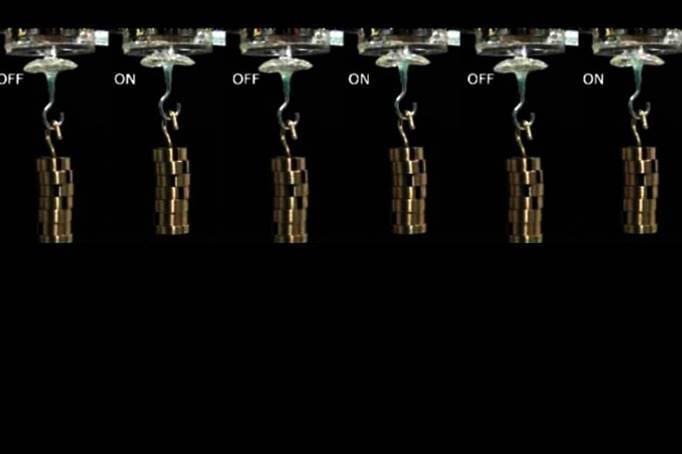

Squid ring teeth are circular predatory appendages located on the suction cups of squid used to grasp prey. If the teeth are broken — they can heal themselves. The soft parts in the proteins help the broken proteins fuse back together in water, while the hard parts help to reinforce the structure and keep it strong.

“Our goal is to create self-healing programmable materials with unprecedented control over their physical properties using synthetic biology,” said Melik Demirel, professor of engineering science and mechanics at Penn State and the paper’s co-author.

Current strategies for material self-healing have significant limitations, including requirements for potentially hazardous chemicals, loss in functionality of the healed material relative to the original state, and long healing times, often greater than 24 hours.

“We were able to reduce a typical 24-hour healing period to one second, so our protein-based soft robots can now repair themselves immediately,” said Abdon Pena-Francelsch, Humboldt postdoctoral fellow, physical intelligence department at the Max Planck Institute for Intelligent Systems and lead author of the paper. “In nature, self-healing takes a long time. In this sense, our technology outsmarts nature.”

The self-healing polymer heals with the application of water and heat, although Demirel said that it could also heal using light.

“Self-repairing physically intelligent soft materials are essential for building robust and fault-tolerant soft robots and actuators in the near future,” said Metin Sitti, director, physical intelligence department at the Max Planck Institute for Intelligent Systems.

By adjusting the number of tandem repeats, the researchers created a soft polymer that healed rapidly and retained its original strength. They also created a polymer that is 100% biodegradable and 100% recyclable into the same, original polymer.

“We want to minimize the use of petroleum-based polymers for many reasons,” Demirel said. “Sooner or later we will run out of petroleum and it is also polluting and causing global warming. We can’t compete with the really inexpensive plastics. The only way to compete is to supply something the petroleum-based polymers can’t deliver and self-healing provides the performance needed.”

Demirel explained that while many petroleum-based polymers can be recycled, they are recycled into something different. For example, polyester t-shirts can be recycled into bottles, but not into polyester fibers again.

Just as the squid the polymer mimics biodegrades in the ocean, the biomimetic polymer will biodegrade. With the addition of an acid like vinegar, the polymer will also recycle into a powder that is manufacturable into the same, soft, self-healing polymer.

“This research illuminates the landscape of material properties that become accessible by going beyond proteins that exist in nature using synthetic biology approaches,” McElhinny said. “The rapid and high-strength self-healing of these synthetic proteins demonstrates the potential of this approach to deliver novel materials for future Army applications, such as personal protective equipment or flexible robots that could maneuver in confined spaces.”

In addition to Army funding, the Max Planck Society, the Alexander von Humbolt Foundation, the Federal Ministry for Education and Research of Germany and the Huck Endowment of the Pennsylvania State University supported this work.

By U.S. Army CCDC Army Research Laboratory Public Affairs

ANOKA, Minnesota – July 29, 2020 – Federal Ammunition was recently given a new $13.8 million delivery order based on its contract awarded in 2017 by the U.S. Army. The order is for 5.56 NATO MK311 Frangible Ammunition, which is better known by ordnance code AA40. This military-grade, training ammunition has a 50-grain frangible bullet comprised of a non-toxic, copper and tungsten powder matrix core, and a gilding metal jacket. It disintegrates into small fragments on impact, minimizing over-penetration and ricochet hazards.

ANOKA, Minnesota – July 29, 2020 – Federal Ammunition was recently given a new $13.8 million delivery order based on its contract awarded in 2017 by the U.S. Army. The order is for 5.56 NATO MK311 Frangible Ammunition, which is better known by ordnance code AA40. This military-grade, training ammunition has a 50-grain frangible bullet comprised of a non-toxic, copper and tungsten powder matrix core, and a gilding metal jacket. It disintegrates into small fragments on impact, minimizing over-penetration and ricochet hazards.