If deemed appropriate by a medical provider, the waterproof casts can be especially useful for military service members, who can return to duty or training throughout the recovery process.

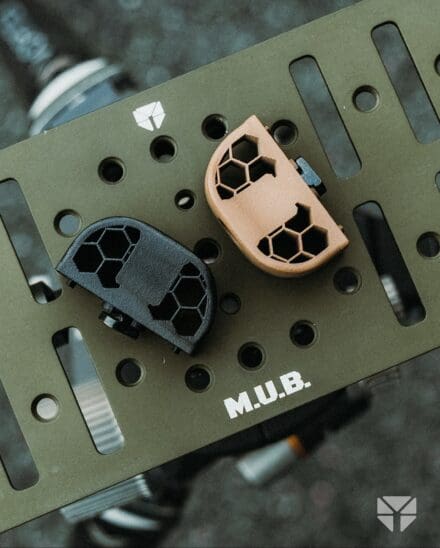

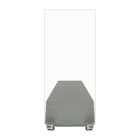

Naval Medical Center San Diego has become one of the first Military Treatment Facilities to adopt a cutting-edge new 3D-printing technology for producing waterproof casts. The technology, developed by ActivArmor, uses additive manufacturing to create breathable casts and splints that allow for improved treatment options with fewer limitations on patients’ activities.

The waterproof casts offer several advantages over traditional fiberglass casts or plaster splints, according to U.S. Navy Cmdr. Kimberly Spahn, department head, Orthopedics, Naval Medical Center San Diego. “You can swim in these and play sports, so they’re great for kids. They’re more hygienic. You can take them on and off so we avoid a lot of the skin breakdown we see with fiberglass and plaster casts,” Spahn said.

Spahn noted that the new casts are not appropriate for all orthopedic conditions, and traditional fiberglass or plaster casts remain an effective treatment in many cases, but if deemed appropriate by a medical provider, the waterproof casts can be especially useful for military service members, who can return to duty or training throughout the recovery process. “It’s great for service members whose training involves water activities,” said Jill Eastin, business manager, Department of Orthopedics Surgery, Naval Medical Center San Diego. “They are able to still go out in the water and continue training in a way that isn’t possible with traditional casts.”

Each cast is custom-fit, allowing providers to make patient-specific modifications, such as amputated fingers or toes, metal pins or other surgical implants, and children with small limbs that don’t fit standard casts or splints, according to U.S. Navy Hospital Corpsman Petty Officer Third Class Danny Berroa Figueroa. “It’s actually a really simple process. We just use the forward facing camera on a mobile device, and we will mark on the skin around bony areas or anything we don’t want to rub, and just scan someone’s arm or leg like that,” said Berroa Figueroa. “Once it’s good, we send it off to an engineer who analyzes it and figures out the best way to create the cast, they send back the guide file and we feed it into the machine to start printing.”

NMCSD is the second MTF to implement the technology, along with Walter Reed National Military Medical Center in Bethesda, Maryland, after ActivArmor received a $1.3 million competitive SBIR direct-to-phase II grant award from the Defense Health Agency. The award “will facilitate the deployment of ActivArmor systems to 11 military bases over 24 months,” according to the company’s website.

The mission of NMCSD is to provide a superior experience for our patients, staff, and warfighters. NMCSD employs more than 5,000 active duty military personnel, civilians, and contractors in Southern California to deliver exceptional care afloat and ashore.

By Seaman Jason Afable, Naval Medical Center San Diego