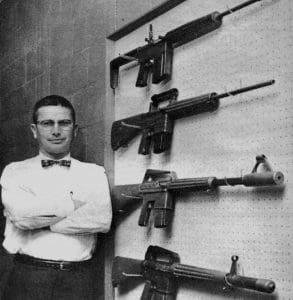

Eugene Morrison Stoner is the father of the AR family of rifles (and everyone knows AR stands for Armalite Rifle), that includes the AR-5, AR-15 and the M16. The family of M16s are one of the most iconic weapons engineered in world history. Stoner worked for the Vega Aircraft Company installing armament units after graduation from a vocational high school and before joining the Marine Corps right after Pearl Harbor was attacked. He served in the Pacific until the end of the war. In 1945 he went to work for Whitaker, an aircraft equipment maker in 1954, he transferred to Fairchild Engine & Airplane Corporation as chief engineer for a newly formed small division called Armalite, which was headed by George Sullivan, a patent counsel for Lockheed Corp. They met at a local range, where Sullivan was testing a new prototype for an Air Force survival rifle.

The AR5, is the product of Eugene Stoner’s feedback on the survival rifle. The AR5 is now better known as the AR7, or Henry Rifle’s US Survival Rifle. Stoner finished the first run of the ArmaLite AR-10 design in 1955. This was a game-changer in the world of small arms – a firearm that was small, quick to shoot, and didn’t weigh a ton. When the AR-10 was chambered for the 7.62x51mm NATO. When it was changed to chamber the new .223 Remington round its name was changed to the AR-15. Stoner’s name would go down in history if he had done nothing but build the AR-15, but he did so much more than that. He was a self-made man with only a high school education. Stoner changed the world as we know it forever, in addition to changing the landscape of American firearms, as well as the world stage, by inventing the M16. That gun, along with the AK (idea stolen from WW2 German guns) family of weapons, are the two most famous guns globally. He also designed one of the most iconic weapons of the Vietnam War and SEAL Team’s history. Eugene Stoner, left ArmaLite around 1961 to join Cadillac Gage Corp. There he started to build an entirely new set of weapons.

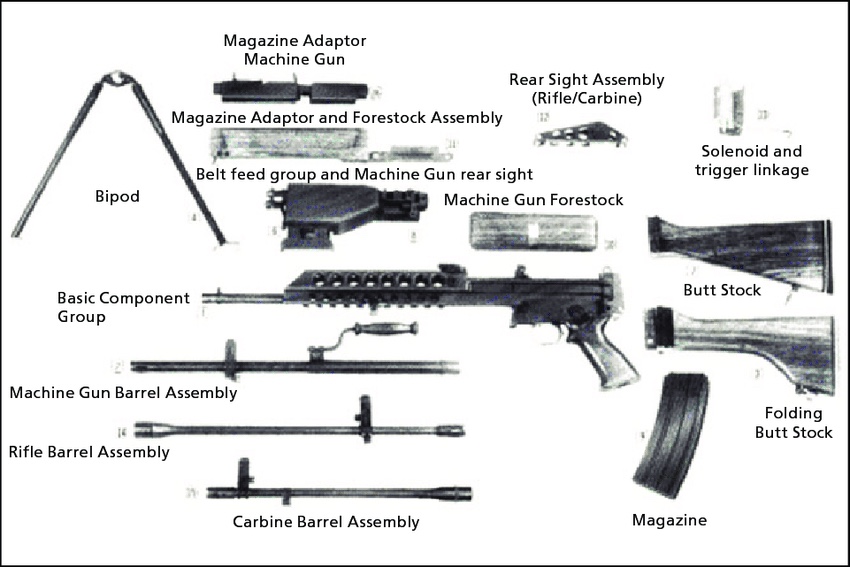

In 1962, known as Stoner 62, the first version, chambered the 7.62x51mm NATO ammunition. Later that year, it was changed to chambered for 5.56mm to help save weight. The name also changed to the Stoner 63. That system, developed and promoted until the early 1970s, was extensively tested as the XM22 (Stoner 63A rifle), XM23 (Stoner 63A carbine), and XM2077 by the U.S. military (light machine gun with belt feed). However, the Mk.23 model 0 belt-fed light machine gun configuration was used in small numbers by both the Navy and some Marines in Vietnam. In general, the Stoner system was somewhat too costly and also slightly over-complicated for a dedicated light machine gun, though having the advantages of modularity and interchangeability of parts allowed for great versatility in tactical use. The Stoner was known for being a little finicky when cleaning and maintaining, but reliable if proper care was taken. Overall, between 1962 and 1971, some 3,500 to 4,000 Stoner M63 weapon kits were made. Of those, some 2400 Stoner 63 Light machine guns were purchased by the U.S. Navy for Special Forces in Vietnam and about 100 more were purchased for the enhanced Mk.23 mod.0 variant. Starting in 1963, the Stoner 63 was used in combat in Vietnam, primarily in the hands of SEAL Teams.

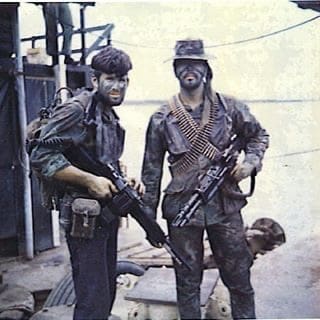

The Stoner machine gun was developed to maximize firepower. The versatility of the Stoner 63 made it the perfect weapons system for the newly minted SEAL teams during the Vietnam War. SEAL Teams One and Two evaluated the 63A, saying that the weapon was “significantly superior” to the M60 machine gun and suggested at least six guns for every 12-man SEAL platoon. It was also claimed that immediate action drills and tactics for contacts with the enemy were based around the weapon system and were actively established by SEAL platoons to fit with the 63A.

One of the last times the Stoner was used by the U.S. Military was by the Marines in limited numbers during the 1983 invasion of Grenada. Despite its success, the Stoner 63 never saw wider acceptance. After the Army provided the 63A Light Machinegun (LMG) version for evaluation to some Green Berets in the 1970s, the branch concluded that the unique platform was too tricky for battlefield maintenance, which is ironic, given that it was the unique recoil buffering mechanism of the Stoner 63 that helped make the platform so flexible in the first place, in combination with the multi-use receiver.

The Stoner 63 framework has several barrel types for LMG models, with different lengths and profiles. Small, fluted barrels were used by the Navy Mark 23 model 0 machine guns, but other models (with long barrels) also saw action in Vietnam.

A universal bolt group is used in the stamped steel receiver, with a multi-lug rotating bolt and a long-stroke gas piston with a gas tube. For the attachment of all other sub-assemblies and the quick-detachable barrel, the receiver also has many sets of mounting points. The receiver is so orientated in the rifle. The carbine configuration is such that the gas device lies above the barrel and the feed unit’s mounting points are below the receiver. Some pictures are so iconic people make shirts out of them( Thirty Seconds Out)

The receiver is turned ‘upside down’ in all machine gun setups, either belt or magazine fed, with the gas system being below the barrel, ejection on the left side, and the feed unit above the receiver. The trigger unit has no hammer in the machine gun configuration; instead, its sear interoperates with the cut in the gas piston rod, only allowing fully automatic firing, and only from the open bolt. The magazine feed unit can handle patented curved box magazines and can be used to configure both rifle and machine gun. It was only possible to use the belt feed unit in machine gun setups.

Early guns had a left-side feed, which often triggered jams due to ejected shells’ reflection back into the ejection window. Later guns had a right-side feed that eliminated this problem. The 100-round box containers, made of plastic, were issued with late production LMG’s with right-side feed. All the containers were clipped to the receiver’s rim, and various rear sight units were available for different setups, with the front sights being mounted on quick detachable barrels. The charging handle was located on the right side of the bolt carrier for the earlier Stoner 63 device weapons; the safety and fire selector were merged into one control, located on the trigger unit’s left side. The charging handle was attached to the gas piston rod on the modified Stoner 63A device and projected from the top in the rifle/carbine configuration or from the bottom in the MG/LMG configuration; safety was formed as a separate lever on the front of the trigger guard, with the fire mode selector still located above the pistol grip on the side of the trigger unit. Plastic was the traditional buttstock and forearm. All Stoner 63 light machine guns were supplied with detachable folding bipods; although Cadillac Gage Corp produced tripods and even vehicle mounts, it seems that they were never really used in combat.

The Stoner machine gun is one of the most iconic weapons of the Vietnam War. I always think about buying an airsoft version just to frame and hang in my garage. But, that said, I started out as a 60 gunner so, if anything, I would have to get an Echo Three first. If you have ever had the opportunity to fire one, you are a very lucky person. Well not in the “hey those guys are shooting at us, I should return fire with my Stoner”. I mean more of the “Hey, I am shooting a Stoner on the range”……not that shooting back at people that are shooting at you is bad thing.