TYSONS CORNER, Va. – Feb. 23, 2026 – Returning from the annual meeting of its global leaders in Iceland during one of the deepest and longest cold snaps in North America, Integris Composites, a leader in military and law enforcement survivability, announced plans to develop a new generation of ballistic composites for troops and equipment that operate in the Arctic Circle.

“A combination of climate warming and global shifts in defense strategy are leading to an increased military presence in the Arctic,” said David Cordova, chief commercial officer of Integris Composites Inc.

Integris Composites, with its global teams of technical and engineering armor specialists in compounding composite armor, testing, simulation, modeling and rapid prototyping, is in a unique position to research and develop lightweight solutions that will perform in harsh, frigid conditions.

“We’ve created the Integris Arctic Armor Development Team (AADT), a cross?disciplinary research, development and engineering squad,” Cordova said. “This AADT team is international. It includes expertise and data from across our global resources,” added Cordova who leads the U.S. commercial team.

“We stand ready to provide independent research and development (IRAD) or contract R&D (CRAD), depending on the situation,” Cordova said, noting that the company has more than three decades of experience developing armor for personnel as well as land vehicles, aircraft, ships and boats.

The new role of the Arctic in defense

Once considered a remote buffer at the top of the world, the Arctic has become a frontline security theater as receding sea ice opens new shipping lanes, resources and avenues of approach to North America and Europe.

Melting ice has already driven a sharp increase in commercial and military traffic, with studies showing double?digit growth in ship movements across the High North over the past decade.

At the same time, Russia has reopened Soviet?era bases, expanded its Northern Fleet and deployed advanced radar and missile systems across its Arctic coastline, while coordinating more closely with China through joint patrols and exercises that extend into Alaskan and North Atlantic airspace. NATO and U.S. planners now treat the region as a critical avenue for power projection, missile warning and homeland defense, investing in new strategies, training and infrastructure to ensure allied forces can fight and survive in extreme cold weather.

In this emerging environment, Arctic?ready protective systems for soldiers, vehicles, aircraft and critical infrastructure are becoming an essential enabler of credible deterrence and sustained operations in the High North.

The time is now

Defense ministries are updating Arctic strategies and accelerating investments because the military balance in the region is shifting in real time.

• Russian and Chinese forces have conducted more than a hundred air and maritime incursions near Alaska and the North Atlantic in recent years, prompting calls in Washington and allied capitals for new ice?capable platforms, hardened bases and cold?weather training across the force.

• Climate change is compressing timelines further as new sea routes shorten transit between Asia, Europe and North America and make northern resource fields more accessible to both state and commercial actors.

Against this backdrop, militaries are seeking partners that can rapidly translate threat intelligence and environmental data into tested, certified solutions that protect people and platforms without compromising mobility or sustainability in subzero conditions.

By launching a focused Arctic armor initiative now, Integris aligns its development roadmap with urgent customer requirements and upcoming procurements, positioning the company to support allies as they redefine what credible defense looks like above the Arctic Circle.

The Integris advantage: experience and accelerated innovation Integris Composites brings more than three decades of experience designing and qualifying lightweight armor for personnel, land vehicles, aircraft and marine platforms, supported by Integris’ experience supporting next-generation vertical lift platforms such as the U.S. Army’s MV-75

Future Long-Range Assault Aircraft (FLRAA) underscores the company’s ability to engineer lightweight survivability solutions to sustain the demanding operating range requirements of the equipment. The company’s integrated development model combines extensive ballistic test data, advanced predictive modeling, high?fidelity simulation and rapid prototyping to compress the cycle from concept to fieldable solution, an approach it has branded “Accelerated Innovation” and is employing on major defense programs such as the U.S. Army XM30 combat vehicle.

Integris applies a data-driven development approach—conditioning materials at controlled environments, validating performance through live-fire testing, and correlating results with high-fidelity modeling and simulations—to ensure composite armor solutions maintain structural integrity, energy absorption, and damage tolerance in Arctic-like environments.

Dedicated ballistic laboratories and an instrumented shooting range allow Integris teams to condition materials at controlled hot and cold extremes, then correlate those results with virtual models to validate performance under Arctic?like temperatures, blast loads, and multi?hit scenarios.

This continuous loop—linking test data, certifications, modeling and simulation—supports multiuse of data across programs, enabling customers to de-risk designs earlier and reuse proven configurations for new platforms or threat profiles.

“We have tested and qualified armor for personnel, vehicle, and aviation applications performance required at cold temperatures, such as seen in the Arctic, across various platforms globally, said Erik Johnson, senior vice president of engineering.

“We have previously demonstrated we can developarmor that performs at the most extreme temperatures, and welcome future development opportunities at those extremes.”

Building on the company’s independent research and development, and customer?funded efforts, the new Arctic Armor Development Team will apply these capabilities to create mission?tailored, rapidly prototyped solutions that help keep warfighters and critical assets protected in some of the harshest conditions on Earth.

About Integris Composites

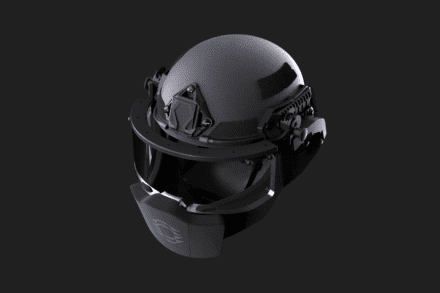

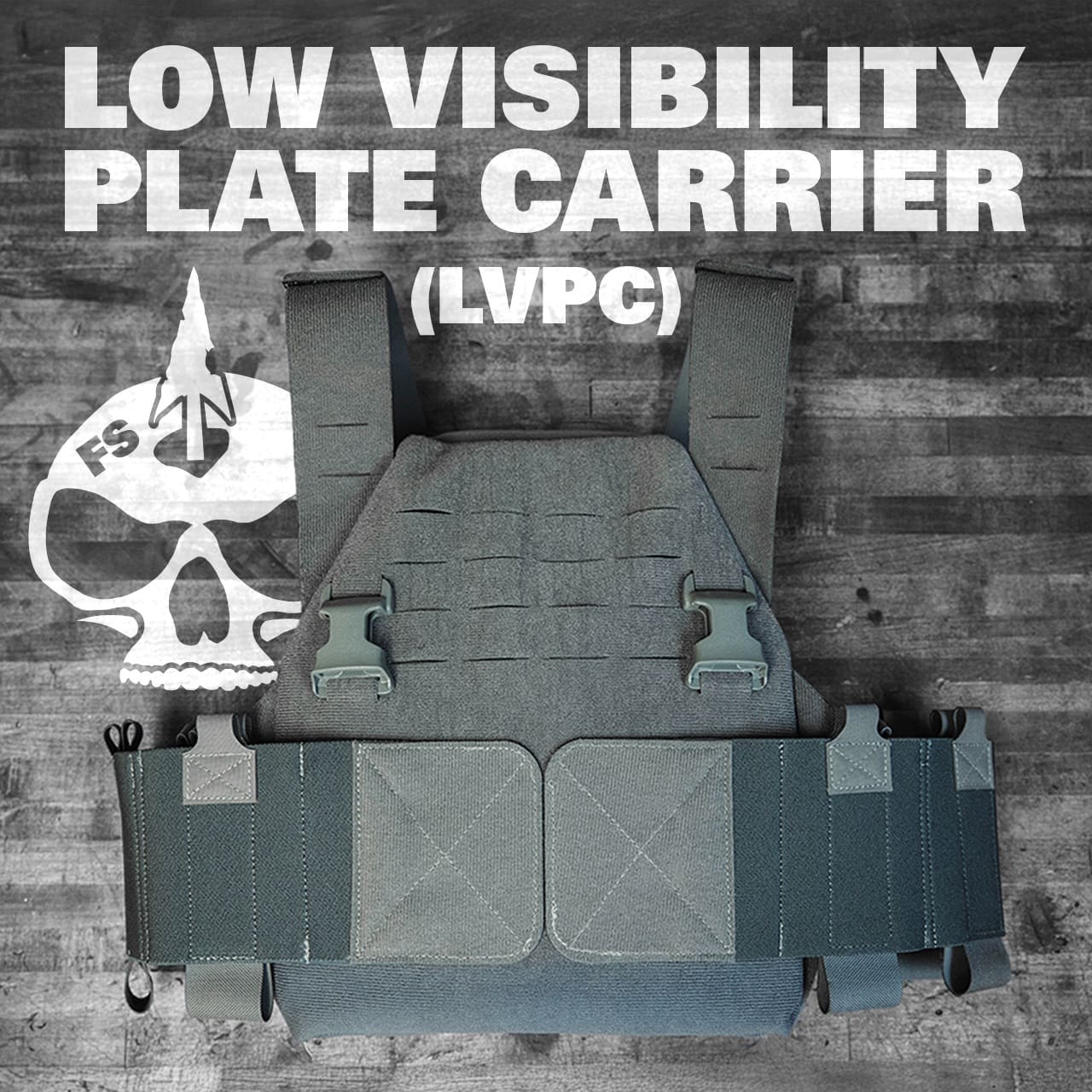

Integris Composites is a global engineering company specializing in composite armor for land vehicles, aircraft, naval vessels, protective housings for optronics and other sensitive technologies, and personal protection. With more than 30 years of experience, the company has earned Tier One supplier status with major aerospace original equipment manufacturers including Bell, Boeing, Airbus and Embraer.

Formerly TenCate Advanced Armor until 2023, when the company was renamed Integris Composites, the business has built a reputation for innovative survivability solutions across military, law enforcement and security applications worldwide.