Yuma, AZ – July 15, 2025 — Fast Metal is proud to announce our official APEL qualification and National Stock Number (NSN) assignment for four of our top ballistic eyewear systems: Fontana, Ozz, Halen, and Zant. It’s not just a win—it’s a warfighter-grade stamp of approval.

These models—engineered for uncompromising protection and all-day performance—are now officially listed on the U.S. Army’s Authorized Protective Eyewear List (APEL): the gold standard for combat-ready eye protection.

Mission-Critical Legends: Fast Metal’s APEL-Listed Eyewear

Each of the following Fast Metal models has been assigned a National Stock Number (NSN), making procurement simple for units, supply officers, and federal buyers:

| Model | Size | MFR Part | NSN |

|---|---|---|---|

| Fontana | One Size | 4-0030-9001 | 4240-01-729-1698 |

| Ozz | Regular | 4-0029-9001 | 4240-01-729-1623 |

| Ozz Compact | Compact | 4-029C-9001 | 4240-01-729-1696 |

| Halen | Regular | 4-0028-9001 | 4240-01-729-1324 |

| Halen Compact | Compact | 4-028C-9001 | 4240-01-729-1344 |

| Zant | One Size | 4-0031-9001 | 4240-01-729-1700 |

What Is APEL?

The Authorized Protective Eyewear List (APEL) is maintained by PEO Soldier and the U.S. Army. To qualify, eyewear systems must pass the most rigorous impact, optical clarity, and durability tests in the industry. All listed products meet or exceed:

- MIL-PRF-32432A ballistic fragmentation standards

- ANSI Z87.1-2020 industrial eye protection standards

- Independent testing at certified government labs

Bottom line: APEL eyewear isn’t just safe. It’s verified, standardized, and ready to serve.

Highlights of Each Fast Metal APEL Model

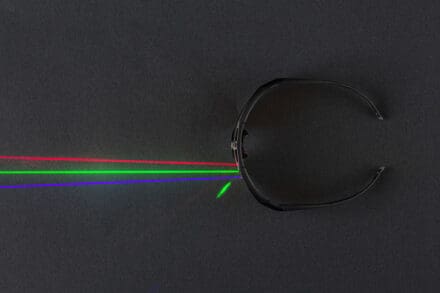

The Only Aluminum Frame on APEL. Versatility That Hits Hard.

Precision-milled aluminum frame and nylon temples deliver rugged durability and interchangeable lens flexibility—all with unmistakable Fast Metal attitude.

Mission-Grade Optics. Maximum Coverage. Zero Distractions.

A minimalist, browless design with an oversized lens for wide field-of-view, superior venting, and full MIL-PRF-rated ballistic protection.

Streamlined. Secure. Solid.

Low-profile and helmet-compatible with adjustable temples—built to stay locked in at full throttle. Two sizes for dialed-in fit.

Built for Speed. Designed to Boogie.

A no-bulk, low-drag hybrid with anti-fog performance, bungee retention, and wraparound protection—born from the KISS principle and built for high-tempo ops.

All models feature interchangeable polycarbonate lenses with anti-fog coatings, scratch-resistant exteriors, and 99.9% UVA/UVB protection.

How to Acquire

Each model listed above is available for order through standard DoD supply chains using the associated NSNs. For federal, state, and agency buyers—or defense contractors seeking bulk orders or teaming options—contact:

About Fast MetalFast Metal engineers ballistic-rated eyewear that protects the elite—warfighters, law enforcement, extreme athletes, and mission-first professionals. Born from precision manufacturing and raised on rock ‘n roll, our name reflects the energy and innovation behind every frame.

Whether you’re clearing rooms or carving trails, Fast Metal gives you vision that doesn’t blink.