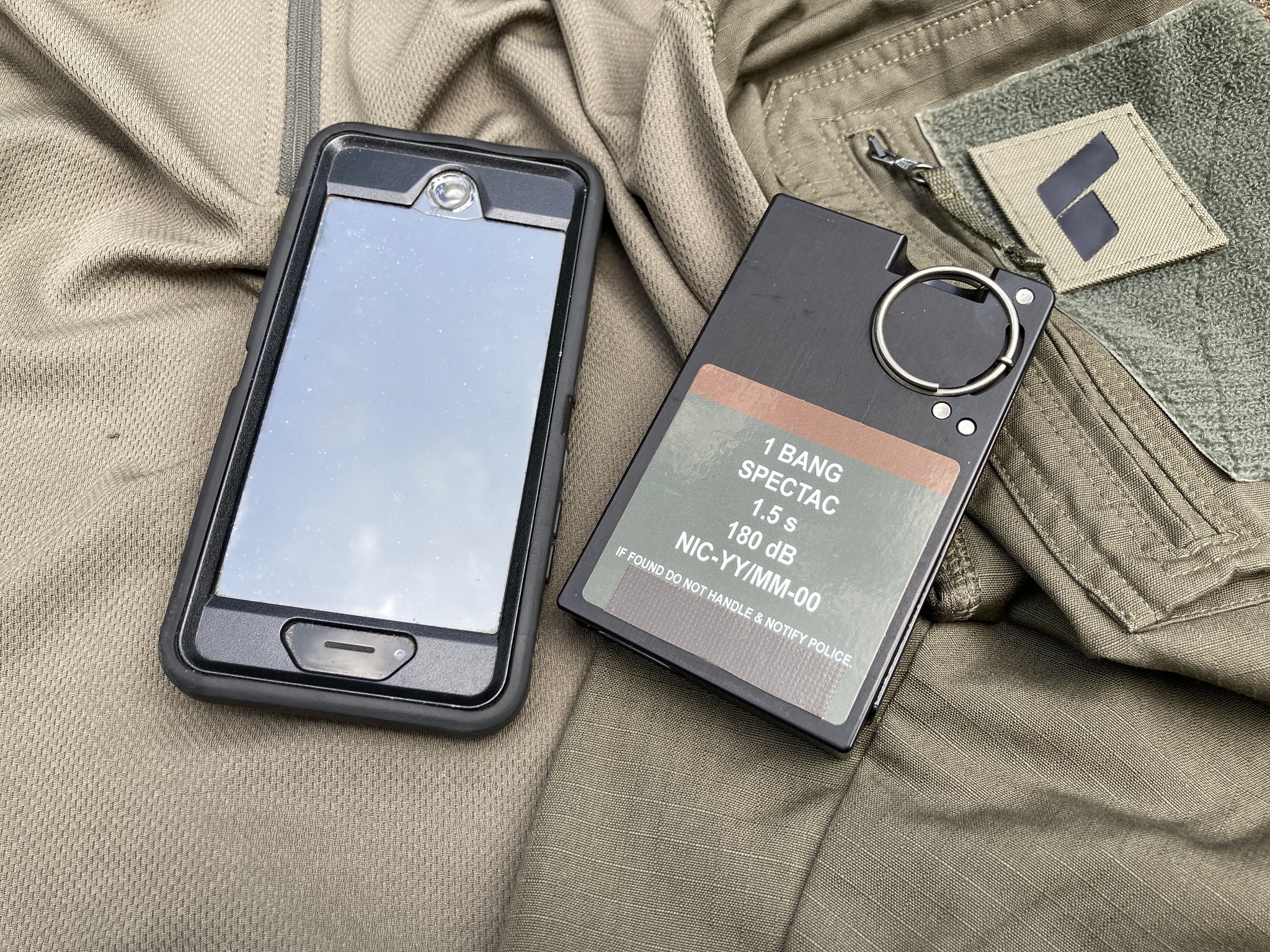

Rheinmetall proudly presents Spectac, its innovative new non-lethal effector. This rectangular stun grenade is specially designed for use by military and law enforcement special operators. The most striking feature of the easy-to-use Spectac is its smartphone-like design, with the locking ring and rocker arm ignitor built into a rectangular housing the size of a mobile phone.

Its novel design offers a number of advantages. Weighing approximately 350 grams, 110 mm long, 63 mm wide and 20 mm thick, this highly ergonomic one-bang stun grenade slips easily into the tactical kit of the special operator, making it very convenient to carry. In addition, its compact design means that it can be discretely taken along on undercover and bodyguard operations. Moreover, its rectangular shape offers other tactical benefits. Unlike traditional round grenades, the Spectac does not roll away in an uncontrolled way after landing, but instead comes quickly to a halt which makes it ideal for the use on stairways. Its maximum movement radius comes to just 35 cm at most. As a result, the desired effect reliably takes place in the intended target zone.

Waterproof at depths of up to 20 metres, the Spectac produces a blinding flash and deafening bang. It is currently available in versions with acoustic pressure levels of 170 and 180 decibels and two delay times, 0.5 and 1.5 seconds. In order to make it even safer to handle, Rheinmetall engineers opted for a tried-and-tested bottom top venting (BTV) design. This way, in the event of an inadvertent detonation, the explosive effect blows out of the top and the bottom of the grenade, reliably protecting the user’s throwing hand. The Spectac does not produce dangerous fragments. Each Spectac grenade is X-rayed prior to shipment, thus assuring maximum functional reliability and safety. The X-ray images are stored for ten years. Neither the percussion cap nor the ignition delay mechanism contain lead compounds. In addition, the grenades are compliant with REACH, the European Chemicals Directive.

Successfully qualified at the end of 2020, the Spectac is available effective immediately. This innovative product confirms Rheinmetall’s role as a leading supplier of pyrotechnic effectors for law enforcement and military applications.