Brooklyn, NY – Jan. 17, 2018 – MultiCam®, the combat-proven, complete family of concealment solutions for those who demand the best, has announced that it will be highlighting some of their major strategic partnerships, to include IMP Anodizing, Techwear USA, Index Fasteners and Flexfit®, at their booth (#32408) at the 2018 SHOT Show, in Las Vegas, held January 22-26th.

The MultiCam® family of camouflage patterns has been extensively tested and proven by the U.S. Department of Defense, Special Operations units and is available to commercial markets around the globe; to include hunting, footwear and high-end apparel brands – from fabric and trim to hydro dip and now anodizing and printed kydex.

IMP Anodizing a leading quality metal finisher specializing in color anodizing and chemical brightening of aluminum parts for almost 60 years, will now serve as the official anodizer for aluminum in MultiCam®, using a process called Permodize®. The agreement between the two companies is structured so that OEM’s will be able to have their products, (rails, uppers, lowers, knives, multi-tools, lights, etc.) anodized in the internationally popular pattern at IMP. To showcase the work, MultiCam® will have Gerber’s 06 Auto, Covert Auto and Mini Covert Auto knives in the anodized MultiCam® pattern on display at their booth.

The partnership between MultiCam® and Techwear USA, a producer of custom ink dyed sublimation polos and jerseys, will now make competitive shooting teams looking for polos, short and long sleeve jerseys in the MultiCam® pattern, available. Customers seeking to use the pattern will be able to incorporate it either into their design or throughout the entire jersey, through Techwear USA. The initial agreement will launch with just MultiCam® with the rest of the catalog of patterns to follow. To showcase the capabilities of the custom ink dye, competitive shooter, Travis Gibson’s, jersey will be on display along with all MultiCam® booth staff will be wearing custom polos.

MultiCam®’s strategic fabric partner, 1947 LLC, will be debuting five new fabrics this year. On display will be XGO’s Phase 1, 4 & 5 moisture wicking fabrics plus Invista’s lightweight NYCO Extreme and 165 AYT 3.6oz nylon.

As previously announced, MultiCam® has partnered with, Flexfit®, one of the world’s largest manufacturer of custom, private label headwear, to offer their pattern on the company’s proprietary stretch fabric on their leading Flexfit® and Snapback styles, Original 6277MC, Snapback 6089MC, Retro Trucker 6606MC and Low Profile 6245MC. All four styles are now available in High volume custom overseas (720pc MOQ) or lower volume custom domestic embroidery (144pc MOQ) in MultiCam®, with MultiCam® Black becoming available Spring 2018. Each of the hats will be on display at the booth, along with representatives from Flexfit®.

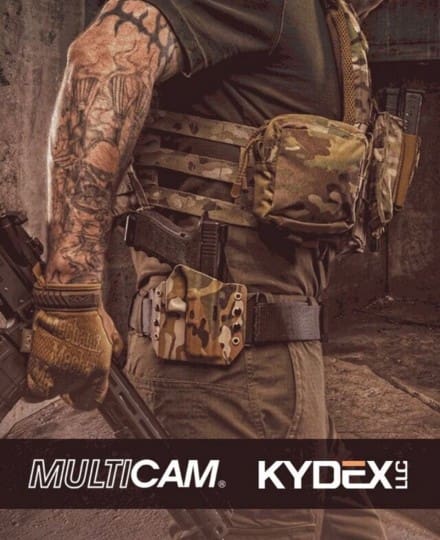

MultiCam® is also announcing their partnership with Index Fasteners Inc, a leader in the Wholesale Fastener Industry to serve as the only kydex supplier to be licensed to print MultiCam® onto kydex for the holster/sheath markets. Currently, only the original MultiCam® pattern is available, with the remaining MultiCam® patterns to be released later this year.

Also on display at the MultiCam® booth, will be products from Vans, New Era, Oakley, and MultiCam® Tees; each set to be available for purchase on the soon-to-be-live MultiCam® webstore (scheduled for launch in Spring 2018).

In addition to the booth display, attendees will also be able to contribute to their favorite military charities through the annual Crye Precision Charity Auction, which will be hosted at the MultiCam booth. Part of that initiative is via the always popular, Hot Shots 2018 calendar. For a suggested donation of $20 you can pick up your very own copy, and have it signed by the Hot Shots Calendar Girls themselves.