OG Lone Star has opened pre-orders on their Logo ball caps in six-color desert camouflage aka chocolate chip pattern festooned with the Lone Star Beer logo.

Secure yours at oglonestar.com/products/chocolate-chip-camo-hat

OG Lone Star has opened pre-orders on their Logo ball caps in six-color desert camouflage aka chocolate chip pattern festooned with the Lone Star Beer logo.

Secure yours at oglonestar.com/products/chocolate-chip-camo-hat

Using the Batlchk Program as a catalyst, Galvion & 4D Tactical have collaborated to develop an exclusive drop-in padding solution.

This easy-to-install kit leverages the popular comfort pads that 4DT is well known for and integrates them into best-in-class Galvion helmet systems equipped with the MSS liner. With hundreds of thousands of MSS liners fielded around the world, this product provides an easy, tool-less retrofit while maintaining the same sizing as your original liner.

The kits are Made in the USA and feature heat and moisture wicking fabric with Anti-Microbial properties. Additionally, the memory foam material conforms to the shape of the wearer’s head.

Only offered in Black, this one-size kit includes:

– Front Brow Pad

– Left Side Pad (J-Shaped)

– Right Side Pad (J-Shaped)

– Nape Pad

shop.galvion.com/products/mss-upgrade-comfort-pad-kit

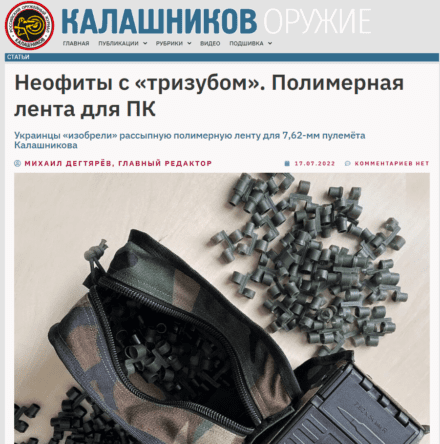

Modern warfare involves the infiltration of contemporary technological solutions. One such innovation is the unique development by the Ukrainian company «Kharkiv Factory of Personal Protective Equipment» RAROG, specifically an ammo logistics system for machine guns PK/PKM.

The metal belt for the PK, PKM, and SG serves as the basis for equipping machine guns, but it is not manufactured either in Ukraine or in the overwhelming majority of the 53 countries that have machine guns in their arsenals. In addition to the shortage caused by the lack of production and constant battlefield losses, the metal belt has several significant disadvantages, including the need to remove it from the battlefield, manual loading of rounds, heavy weight, masking noise, corrosion, and so on.

Experts from the Kharkiv Factory of Personal Protective Equipment (Ukrainian Defence Innovations (UDI) Group, former Rarog Group) have found solutions to all these issues by developing a world`s first polymer disintegrated links for machine gun ammo belt, which significantly improves the mobility and effectiveness of machine gunners on the battlefield. This fact has been proven both through field testing and in actual combat. First samples were tested back in 2016. In 2019 Rarog won Sikorsky challenge (competition of innovative startup projects), suggested a new ammo logistic system for Armed Forces of Ukraine based on polymer links.

The polymer machine gun belt consists of a series of links, each of which has three rings connected by a crossbar. The links are hinged and connected by cartridges inserted into the aligned rings. This belt is three times lighter than the metal analogues, has low cost and high production speed, minimal noise during transportation, no corrosion, and prevents snags during operations. A key difference of this system is that the belts could be supplied to the combat zone already loaded, so soldiers do not need to spend time on this task. The standard machine gun belt for the PKM is supplied in solid links of at least 25 units. This creates inconvenience when shooting, the so-called tail. The links of the polymer belt simply fly out along with the cartridge cases. The metal belt must be collected and reloaded, the polymer belt is one-time use (although in training ground conditions Ukrainian soldiers use it up to 4 times in a row). Also, cartridges loaded into a metal belt are subject to corrosion during storage. This creates a risk that the machine gun may fail in a critical situation. Cartridges loaded into a polymer belt make less noise when moving as well.

The development and testing process of the polymer belt took much time, as Rarog aimed to ensure maximum convenience, reliability, and efficiency in this product. UDI Group`s representatives are in constant communication with Ukrainian defenders participating in combat operations on various parts of the frontline, and receive feedback from them. Over the course of the war, the polymer belt produced by the Kharkiv Factory of Personal Protective Equipment has been used by the soldiers of Airborne Assault Forces, 54th Separate Mechanized Brigade, 24th Separate Mechanized Brigade, 3rd Separate Assault Brigade, and other units of the Armed Forces of Ukraine. Soldiers have praised the ergonomics, ease of transport and versatility of the polymer machine gun belt.

The opponents did not ignore this product. In 2022, an article was published on the website of the well-known Russian magazine «Kalashnikov», where the author, a weapons expert and editor-in-chief of the publication, Mikhail Degtyaryov, accused the experts from Rarog of «lack of professional knowledge and ignoring historical experience», while also emphasizing that replacing the usual metal belt with a much lighter and cheaper polymer one was impossible due to several critical shortcomings.

However, two years later, several Russian companies introduced their «new products» – analogs of Ukrainian development, one of which even made it to the cover of the aforementioned expert magazine.

FORT GREELY, Alaska — Deployed Soldiers are constantly loaded with gear, but are particularly encumbered when operating in a cold weather environment.

In addition to their conventional weapons, Soldiers need to utilize heavy equipment like space heaters, cooking stoves, fuel and heavy-duty thermal tents to survive operations in arctic climates.

The Army’s Arctic Mobility Sustainment System, or AMSS, all-regions tactical clothing with updated cold weather clothing, snowshoes and ski poles underwent rigorous testing at U.S. Army Arctic Regions Test Center — known as ARTC — this winter with the help of Soldiers from the Army’s 11th Airborne stationed at Joint Base Elmendorf-Richardson.

“We’re traveling longer distances to get the snow that we need,” Hannah Henry, ARTC test officer. “We’re getting a lot more data this year.”

The AMSS items under test will replace the legacy Ahkio sled and 10-person tent the Army currently uses. Testers expected extreme cold for the multi-week test, and the interior Alaska winter delivered a wide span of Arctic conditions, from brutal temperatures below 0 degrees Fahrenheit to rapid, but short-lived swings to relatively mild winter temperatures only slightly below freezing.

“We’re testing some different base layers,” said Steven Prewitt, ARTC test officer. “Our unusually warm winter here has been very good for observing insulating and moisture management factors with the clothing.”

On a typical day, Soldiers would pack an AMSS sled under test with the tent, a heater, and their basic standard issue items for arctic infantry operations, then pull the sleds in either nine-Soldier squads or four to five Soldier teams as ARTC’s test personnel led the way. Moving the heavy sleds across CRTC’s hilly tundra, thickly forested areas and the dense, frozen boggy vegetation called muskeg is challenging in any conditions, but particularly so in extreme cold and deep snow.

“Our snow is so dry and powdery,” said Isaac Howell, Chief of ARTC’s Test Operations Division. “You don’t stand on it at all, whether you are on skis or in snowshoes — you don’t go across the top of it, you go through it. You are plowing snow the entire day regardless of whether you are wearing snowshoes or not.”

After a two-and-a-half-hour movement, testers kept track of how long it took the soldiers to emplace and erect each tent and get the space heaters operating. Following a cold weather MRE for lunch, the Soldiers disassembled the tent and heater and returned to their day’s starting point following a different route. Following a sensing survey on their opinion of the items and hot meal, the Soldiers reassembled the tents and heaters and prepared to sleep in the long, cold Arctic night.

Through it all, telemetry on the Soldiers measured their body core and extremity temperature for both feedback on the clothing and for safety. They also participated in a comprehensive feedback focus group every week that will be used when assessing the effectiveness of the tested gear.

By Mark Schauer

SAN DIEGO – 20 March 2025 – General Atomics Aeronautical Systems, Inc. (GA-ASI), a world leader in unmanned aircraft systems (UAS), has received the prestigious EMAR/FR 145 Maintenance Organization Approval for component maintenance from the French Military Continuing Airworthiness Authority, DSAE. This approval underscores GA-ASI’s commitment to the highest standards of safety, compliance, and operational excellence in military aviation.

The EMAR framework is a set of regulations developed from commercial aerospace standards (FAA/EASA) that are designed to ensure airworthiness for European military aircraft. It establishes a common airworthiness framework recognized by military airworthiness authorities worldwide. EMAR/FR 145 certification authorizes maintenance organizations to perform critical maintenance tasks while ensuring strict adherence to safety, reliability, and documentation requirements.

GA-ASI’s EMAR/FR 145 approval allows the company to issue EMAR Form 1s (Return to Service forms) for components serviced by the approved maintenance organization, confirming the safety and airworthiness of the equipment. This recognition applies to GA-ASI’s maintenance activities at its Poway and Adelanto, California, facilities and covers CAT C (component maintenance) services.

“This approval is a significant achievement for GA-ASI, positioning the company to better serve international customers, especially military users of our MQ-9A and MQ-9B UAS platforms,” said Sam Richardson, GA-ASI vice president of Sustainment. “The ability to leverage the EMAR/FR 145 certification streamlines the company’s processes, reduces costs, and accelerates future airworthiness pursuits, as many future customers will recognize this certification rather than requiring a full, independent certification process.”

By obtaining EMAR/FR 145 approval, GA-ASI further demonstrates its ability to meet the stringent demands of the global defense market. The framework’s widespread recognition ensures that GA-ASI can expand operations and offer high-quality, compliant maintenance services to international customers, ultimately driving company growth in global markets.

This certification offers significant operational and financial benefits for both GA-ASI and its customers. For GA-ASI, the approval reduces future oversight costs by leveraging the DSAE Audit Team’s oversight activities, ensuring a more efficient and cost-effective certification process for future non-French EMAR customers. For customers, the EMAR/FR 145 approval provides a framework recognized internationally, offering a streamlined maintenance certification process. The recognition agreements between EMAR and non-EMAR countries allow future customers to leverage GA-ASI’s French approval, saving time and resources compared to a full certification effort.

U.S. Army Gen. Bryan P. Fenton, commander of U.S. Special Operations Command, joined congressional leaders March 26, 2025, to underscore the indispensable role of special operations forces and rally bipartisan support for their growing mission at the Congressional SOF Caucus event on Capitol Hill.

Fenton highlighted the unprecedented demand on SOF, driven by escalating threats from state and non-state actors alike, during his remarks to the caucus co-chaired by Representatives Richard Hudson, Kathy Castor and Scott Peters.

“The demand from your SOF is higher than it’s ever been,” Fenton said. “Crisis response missions are up 170% in three years, and deterrence taskings have risen 35% in two.”

Hudson, representing North Carolina’s 9th Congressional District, home to Fort Bragg, opened the event by detailing SOF’s vital footprint nationwide — from his state to Naval Base Coronado in California. He emphasized the strain on operators and their families amid the relentless operational tempo.

“We give you a broom handle and some bailing wire, and you go do it, and you’re excellent,” he said.

Hudson’s focus on resources echoed a recurring theme of the evening. Castor, a co-chair from Tampa, Florida — home to Socom headquarters — pointed to the disparity between SOF’s outsized contributions and its modest share of the Defense Department’s resources.

“You carry the load on the most sophisticated missions out there with just 2% of the defense budget,” she said.

Castor pressed for modernizing the command’s aging facilities at MacDill Air Force Base, contrasting those with U.S. Central Command’s state-of-the-art headquarters nearby.

“It’s time for that headquarters to live up to what we ask of the men and women who serve,” she urged, calling for bipartisan backing to ensure SOF’s infrastructure matches its mission.

The critical value of SOF emerged as a cornerstone of the discussion. Peters, representing San Diego’s Naval Special Warfare community, cited a recent bipartisan win — securing $310 million to address sewage flows impacting SEAL training waters — as proof of the caucus’ impact. He stressed SOF’s role in deterrence and crisis response amid threats from China, Russia, Iran and terrorist groups.

Fenton elaborated on SOF’s unique adaptability, describing the current era as “a SOF renaissance” tailor-made for converging challenges like unmanned systems and artificial intelligence. He cited recent successes, including eliminating hundreds of terrorists and rescuing Americans abroad.

“We’ve been called out 14 times in three years on short notice to be somewhere in the world,” he said.

He urged sustained investment in scalable capabilities to keep pace with adversaries exploiting new technologies.

Colby Jenkins, a former Geen Beret and combat veteran, who is currently performing the duties of assistant secretary of defense for special operations and low-intensity conflict, emphasized SOF’s relational edge. He praised the caucus for supporting families and empowering Socom as a service-like entity.

“That’s where we bring value — with relationships of trust that span decades,” Jenkins said.

Fenton also called for deeper ties between Socom and Congress to address installation needs and family support. He lauded the caucus’ role in bridging gaps for members without SOF bases in their districts, ensuring broad awareness of the community’s challenges.

“You watch over our families — we couldn’t do what we do without them,” he noted.

Fenton expressed confidence in SOF’s readiness, bolstered by the caucus’ commitment, highlighting the need for bipartisan resolve to equip operators for an uncertain future.

“SOF readiness is important now more than ever. “[Our] job [is] to … make sure that you’re getting the resources you need, the training you need and support you need,” Hudson said.

By Army MAJ Wes Shinego, DOD News

ARLINGTON, Va. — Leonardo DRS, Inc. (NASDAQ: DRS) announced today that it has received a prototype project award by the U.S. Army to modernize the Paladin Electric Servo Amplifier (PESA) electric weapon control system for the M109A7 Paladin self-propelled howitzer. The OTA award is worth $16.9 million.

The PESA is a critical technology to the operation of the M109A7. Under the project award Leonardo DRS will develop a next-generation prototype with current electrical technology to improve the producibility and maintainability of the line replaceable units and enable the continued operation of the vehicle with no degradation to current capabilities.

“Paladin is a mission critical combat system, and our agility and leading-edge capabilities ensure our U.S. Army partner has the necessary capabilities to support our warfighters for the long term,” said Denny Crumley, senior vice president and general manager of the Leonardo DRS Land Electronics business unit. “We are thrilled to be providing this next generation of technology to the Army’s M109A7 Paladin combat vehicle.

Leonardo DRS is a leading designer, developer, and integrator of sophisticated electrical, electromechanical and electronic systems, subsystems, and assemblies across the U.S. military. The work on PESA is another example of providing best-of-breed technology and capability to deliver on a wide range of customer needs from electrical power, network computing, and advanced sensing.

ST. AUGUSTINE, Fla. – March 21, 2025 – SK Guns® is proud to announce the next edition of its collaboration with Agency Arms, Stan Chen Customs and Color Casing by the famous “Doug.” The Agent Eclipse AOS 1911 is the follow-up to the Agent Firecrest AOS 1911 pistols, which sold out of all 300 limited units within days. The companies have come together again to offer the latest rendition in both 9mm and 45 ACP. In addition to para-ported and chunk-ported options, the Agent Eclipse will have three variations of the popular REACTIV™ Maxx grips.

“We received an immense amount of positive feedback following the launch of the Agent Firecrest AOS 1911,” said Simon Khiabani owner and founder of SK Guns. “Along with that feedback, we received an overwhelming amount of requests for a two-tone variation. We have listened to our loyal customers, and are proud to introduce the new Agent Eclipse. It has been a great experience working with Agency, Stan Chen and the famous ‘DOUG’, and I am excited to see these partnerships continue to grow.”

Each model in the Eclipse lineup includes the AOS optic plate, compatible with the RMR/SRO A14B footprint. The Eclipse is a two-tone model with satin Black Nitride controls, slide and barrel, the most durable finish available for a firearm. An iron sight cover plate is also provided in the same satin finish to offer versatility for shooters who prefer not to use optics.

The serrations are more aggressive than ever, and the frame and one-piece Stan Chen Customs mainspring housing and magwells are highly polished and color-cased by “DOUG”. Each firearm is equipped with Wolff reduced recoil springs specialized for the calibers, as well as XP firing pin springs. The full-size government frame provides a solid foundation for handling, while the integrated Picatinny rail allows for the attachment of various accessories.

With a 1:16 rate of twist, the stainless steel barrel finished in Black Nitride ensures accuracy and reliability, complemented by a forged carbon steel frame and slide that enhances durability. These features make the Agent Eclipse AOS pistols a standout choice for both competitive shooters and recreational users alike.

The Agent Eclipse AOS pistols are available to ship now. The para-ported variation starts at an MSRP of $1,950, while the chunk-ported configuration starts at an MSRP of $1,975. Visit www.skguns.com to learn more.

Dealers are welcome to sign up here for bulk pricing.