ABERDEEN PROVING GROUND, Md. — When Soldiers took to the field for Project Flytrap 4.5, they were not only testing emerging counter-unmanned aerial system technology but also tackling a challenge facing multinational operations: how to move sensor data quickly, reliably and securely across networks.

Project Flytrap is a recurring C-UAS experimentation series in Europe focused on assessing passive and active sensors, and defeat capabilities against group 1-3 UAS in a coalition environment. Conducted by V Corps alongside U.S. and partner nation forces, the exercise series is designed to identify capability gaps, test new technologies and refine tactics under realistic operational conditions.

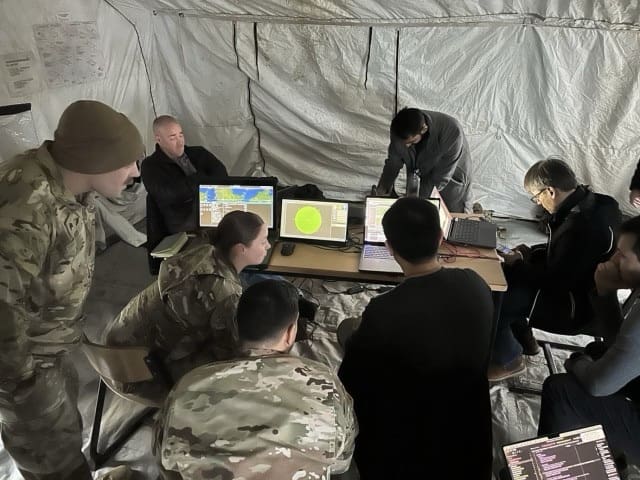

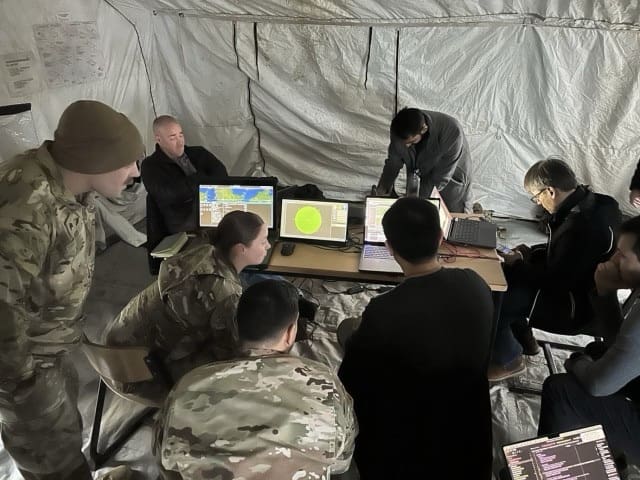

As part of the exercise, Army teams worked alongside V Corps to evaluate how the integrated sensor architecture, or ISA, could help address data sharing and interoperability gaps revealed during earlier iterations of the exercise.

Developed by Capability Program Executive – Intelligence, Electronic Warfare and Sensors, ISA is a framework that connects sensors and networks across domains, services and coalition partners using standardized, open-architecture data formats. As demand for rapid, interoperable sensor data grows across Europe, ISA has emerged as a scalable, plug and play backbone for operations.

“The goal is a plug and play environment where partner nations can bring in their sensors and contribute to a common operating picture,” said Russell Nadler, a technical program integrator with CPE-IEW&S’ Integration Directorate. “ISA can be the enabler that helps pass sensor data seamlessly between allied and U.S. systems.”

Conducted over multiple iterations in recent months across locations in Germany and Poland, Project Flytrap supports the Eastern Flank Deterrence Line warfighting concept by bringing U.S. and partner-nation soldiers together to evaluate new technologies under realistic conditions. Previous iterations exposed limitations in existing networks, particularly when integrating multiple sensors and processing large volumes of data in real time.

“For us, Flytrap really highlighted the importance of having an architecture that could scale and adapt as systems were added,” said Maj. Oniel Rhooms, Project Flytrap network integration lead for V Corps. “By the time we got to 4.5, ISA had matured to a point where it could actually enable that integration instead of becoming another barrier.”

Built for Interoperability

By leveraging open data standards, ISA enables information from radar, optical, infrared and acoustic sensors — regardless of origin — to flow into a shared environment without custom re-coding or system-specific interfaces. This approach provides a more flexible and resilient way to integrate sensors across units and coalition partners.

“ISA wasn’t just part of the network, it was also part of how we validated vendors,” Rhooms said. “It helped us determine early on whether systems could actually connect and deliver what they claimed, which saved time and reduced risk once we went live.”

That flexibility extended beyond technology. Rhooms emphasized the importance of the ISA team’s on-site support, noting their ability to adapt quickly as conditions changed.

“The people mattered just as much as the technology,” he said. “They were able to pivot, solve problems on the spot, and make connections happen that otherwise wouldn’t have.”

Looking ahead

As adversary drone tactics continue to evolve, exercises like Flytrap remain essential for testing technologies under real-world stress. With Flytrap 4.5 demonstrating the value of a more integrated approach, V Corps and CPE-IEW&S will continue refining how ISA supports interoperable C-UAS and sensing operations across the European theater.

By Kay Edwards