BARNEVELD, Wis. – Tactical professionals know the battlefield never stops evolving, and the optics they carry to meet new challenges shouldn’t either. Vortex® is proud to offer professionals and advanced competition shooters the powerful, versatile tool they need to conquer mid- to long-range engagements: the New Razor® HD Gen III 4-24×44 FFP Riflescope available now in MOA and MRAD.

At 12.5″ long and weighing just 32.3 ounces, the Razor®HD Gen III 4-24×44 FFP Riflescope offers a more compact optic for today’s more compact rifles.

Smaller Size. Bigger Impact.

Built to fit more compact DMR-style rifles, this new Razor® reduces form factor without compromising on optical horsepower or clarity. The 4-24×44 configuration allows for a wide field of view for identifying targets, with ample magnification to engage at longer ranges. With the Razor’s legendary glass and sophisticated optical system, shooters can quickly identify targets throughout the magnification range in high stakes scenarios where speed is essential.

Every component in the Razor® HD Gen III 4-24×44 FFP Riflescope is optimized for versatility and speed.

The Versatility to Conquer Any Environment.

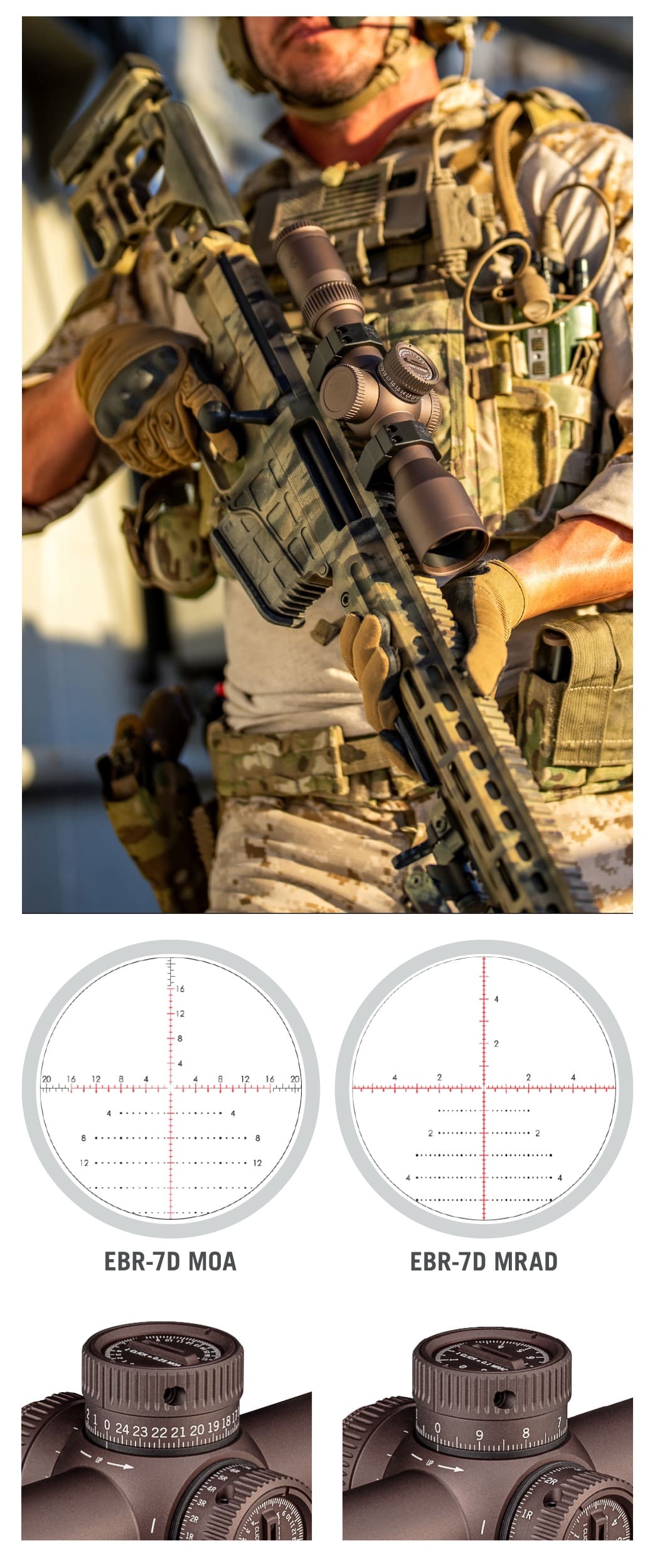

Internally, the Razor® HD Gen III 4-24×44 FFP Riflescope brings together a powerful suite of mid- to long-range tools. The EBR-7D FFP illuminated reticle reduces visual clutter, pushing wind hold numbers out to maintain a clear sight picture while still providing plenty of subtension data for more refined holds. At the same time, cross-plex and center dot rotary illumination power lower mag engagements, keeping you on target in any light.

The L-Tec+™ Zero System and locking elevation turret also enable shooters to quickly dial adjustments with the confidence of an immediate return to zero. The complete package combines all the tools pros need to win when

facing dynamic, unpredictable shooting scenarios.

A Razor® HD Gen III for Every Job.

The Razor® HD Gen III 4-24×44 FFP Riflescope slots perfectly into the Razor® HD Gen III lineup, filling the middle ground between the Razor® HD Gen III 1-10×24 FFP Riflescope and the Razor® HD Gen III 6-36×56 FFP Riflescope.

Razor® HD Gen III 4-24×44 FFP Riflescope

MAP $2,799.99 | MSRP $4,499.99

For a detailed list of technical specifications, frequently asked questions, and high-resolution images, check out the Vortex® new product portal.

To see more from Vortex®, visit VortexOptics.com or follow us on Instagram, Facebook, YouTube, X, and TikTok.