DroneShield is pleased to release the 7th Edition of the C-UAS Factbook. The Factbook provides information on key trends in the C-UAS market, the emerging UAS threat, C-UAS Solutions, and much more.

The C-UAS Factbook can be viewed here.

DroneShield is pleased to release the 7th Edition of the C-UAS Factbook. The Factbook provides information on key trends in the C-UAS market, the emerging UAS threat, C-UAS Solutions, and much more.

The C-UAS Factbook can be viewed here.

Mi-TIC S Thermal Imaging Camera Supports Naval Firefighting Operations, Including Search and Rescue and Casualty Response

MELKSHAM, ENGLAND (Nov. 10, 2022) – Avon Protection has received two orders from the U.S. Navy amounting to 584 Mi-TIC S thermal imaging cameras.

The Mi-TIC S was specifically tailored to meet the requirements of the U.S. Navy Damage Controlman firefighting teams and is being rolled out across the fleet as part of an ongoing equipment modernization program.

“This is a significant win for Avon Protection, as well as our strategic partner Darley, who we worked closely with to secure the orders,?and demonstrates our commitment to navy firefighter teams and the critical role they play in keeping deployed maritime forces safe on operations,” said Erik Cobham, Vice President Department of Defense, for Avon Protection. “The Mi-TIC S is globally regarded as a best-in-class product, and we are extremely pleased that the U.S. Navy has continued to put their faith in our leading protection products.”

Part of the argus® range of thermal imaging cameras from Avon Protection, the Mi-TIC S is a premium, lightweight thermal imager with industry-leading dynamic range and large display for top performance in the most extreme firefighting environments. The camera provides a crystal clear image with a dynamic range up to 2000°F (1100°C). It allows users to clearly view extremely high temperatures without whiteout, as well as very low temperature objects. Proven in some of the toughest operating environments, the Mi-TIC S is in use with both sea and shore-based firefighters globally.

The argus® Mi-TIC range of thermal imagers represents the most extensive offering of thermal imaging cameras certified to comply with the latest NFPA 1801:2021 standard. The line is designed and manufactured to the highest levels in the United Kingdom.

Learn more at www.Avon-Protection.com.

5.11 Tactical, the global innovator of purpose-built apparel, footwear and gear, will show its appreciation to those who serve with a special Salute to Service event this weekend, Friday, Nov. 11 through Sunday, Nov. 13. The event offers a 25% discount off entire purchases, both in-store and online, to customers who verify eligibility.

With its roots in servicing law enforcement, first responder, military and medical communities, 5.11 wants to show its gratitude specifically to those who dedicate their lives and careers to serving others.

Military personnel, veterans, first responders, fire and emergency medical services, and medical professionals are eligible to receive the offer once they verify their eligibility with a valid ID in-store or through ID.me online.

“These incredible groups of people routinely commit themselves to providing for others while serving their communities and we want to offer them a sign of our appreciation,” said 5.11’s Chief Executive Officer, Francisco J. Morales. “We can’t thank these heroes enough, but the Salute To Service event is one way we want to offer our gratitude.”

Customers can shop online at www.511tactical.com or locate a store near them by visiting www.511tactical.com/store-locator. The event will take place Friday, Nov. 11 through Sunday, Nov. 13.

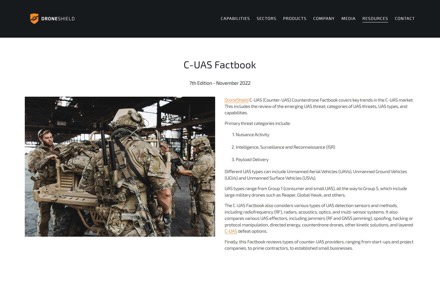

We thought this recent blog post by CRO Medical was worth a share.

The CRO Medical Hybrid IFAK has been in circulation for over five years, with over 10,000 units sold. We designed this product as an improved medical fanny pack for POI care during the first ten minutes of treatment. The bag dimensions accept a six-inch ACE wrap packed vertically in the pouch. The molle wings allow two CRO Medium Bleeders to attach for expanding the kit. There are endless ways to utilize this product. Here is one medic’s approach to packing, treatment, and planning using the Hybrid IFAK.

Why is this fanny pack more valuable to a medic?

It’s compact and allows me to carry all of my lifesaving interventions that are more advanced than a teammate’s standard IFAK. These advanced interventions include diagnostics, drugs, advanced airway, and IV/IO admin. I can provide point-of-injury care for the first ten minutes of treatment and upgrade my patient’s condition as I prepare for Damage Control Resuscitation. I accomplish all of this using only my Hybrid IFAK. This product allows me to rapidly deploy treatments, only needing to drop my med bag if the patient needs blood. The integrated waist belt will let me quickly switch the Hybrid IFAK from back to front and stow it again when not used. The versatility of this product is unmatched for POI care.

What are some of the desirable features of this bag?

The customizable bungee retention in this bag is excellent. It expands your carrying capabilities on your waist instead of filling up space on your plate carrier. It doesn’t limit you to certain-sized items fitting in premade loops but provides excellent retention and easy customization. This feature is unique to CRO and found in all of their equipment. The internal vertical sleeve pockets are convenient for flatter and smaller items, as they can hold many of them, including NCDs, casualty cards, chest seals, etc. However, one of the best features is the wings on the sides of the IFAK that can fit CRO Medium Bleeder pouches or tourniquet covers.

How do you utilize this product while treating a patient?

After doing a rapid MARCH assessment or treating a casualty that is being treated by teammates already, I can quickly reach into the Hybrid IFAK and access a premade kit such as an IO, IV, or suction and pass it off to somebody to use. At the same time, I can focus on blood admin/preparation, drug admin, or preparing more advanced interventions as needed. The ability to carry medic-specific items in the “hybrid” IFAK style pouch is ideal and makes a ton of sense for medics integrated into a team.

What other uses have you found?

I had extra space in one of my Medium Bleeder pouches after packing a pulse-ox and EMMA device. I decided to throw in some basics that aren’t lifesaving interventions but still are valuable for patient care. Tape is always needed, and by running the bungee through the roll of tape at the top of the pouch, I found that it sat perfectly above the pulse-ox and EMMA to give the bag a fuller feeling. Additionally, I found room for a headlamp. Headlamps are always needed in a pinch, and if I were to only have my Hybrid IFAK on in a dark environment, I could quickly reach in and throw that on and continue patient care.

Please describe your methodology for packing this product and how it relates to the MARCH algorithm.

When building out my Hybrid IFAK, I wanted it to be more advanced than a teammate’s IFAK and have enough interventions to treat a casualty or two almost entirely without digging into my med bag. It has primary interventions for “M” in the MARCH algorithm (extra wound packing supplies) and advanced interventions for ARC (cric kit and basic suction/finger-thoracostomy kit/IV/IO, along with a premade TXA kit). It is a perfect middle-ground between an IFAK and my med bag.

What have you found while using this product while running trauma lanes?

While training, the Hybrid IFAK sits on my lower back. When I need to treat a patient, I rotate it around to grab supplies quickly, and if I’m in a secure position and can sit on the patient for a few minutes, I detach it from my waist and place it next to me or on the patient. Running slimmer mag pouches/placards makes visualizing its contents much easier when it’s on your waist. Wearing a dangler pouch below my plate carrier tends to impede working out of the Hybrid IFAK, making things a little more awkward regarding accessibility. I suggest running either a dangler or the Hybrid IFAK, but not both.

Please describe other benefits of integrating this product into your planning and treatment of casualties.

In short, the compact size and customizability of the Hybrid IFAK give me the confidence to treat one or two patients without digging into my med bag. By fully utilizing the Hybrid IFAK, I increase my maneuverability and save valuable size/space in my med-bag.

While TNVC is happy to participate in the retail tradition of offering some of best discounts on some of the most sought-after products on the market this year—we nevertheless want to take a moment to first remember what Veterans Day is truly about. Veterans Day is not about the sales, discounts, or free meals. Veterans Day is about those who have stood up to be counted in defense of our great nation—a nation, an idea, a set of founding principles, and a way of life that need constant vigilance, constant effort, and constant defending: “this nation will remain the land of the free only so long as it is the home of the brave.” To all Veterans, past, present, and future—our sincerest thanks and our deepest gratitude.

~The TNVC Team

tnvc.com/shop/category/brands/tnvc/veterans-day-sale-2022

TNVC’s 2022 Veterans Day Sale features some of the deepest discounts we’ve ever offered on some of the best gear available on the market! Let’s face it, over the last year, inflation has been a kick in the pants—everywhere you turn, prices have gone up on everything from milk to real estate.

All sale items are in-stock and ready to ship with limited quantities available—once they are gone and with 2023 around the corner, prices like these are not likely to return.

Kicking things off—the L3Harris BNVD-1531:

tnvc.com/shop/l3harris-bnvd1531-binocular-night-vision-device

The BNVD-1531 is one of the true workhorses of the night vision world—adopted by the U.S. Army EOD as their standard issue goggle, the BNVD-1531 shares many similarities with its older brother, the AN/PVS-31, featuring a similar rugged chassis, articulating optical pods, manual gain control, and flash protection circuitry that protects the High Performance 2376 Minimum Figure of Merit (FOM) Unfilmed White Phosphor image intensifier tubes, providing exceptional image quality, situational awareness, and target identification. Limited numbers of these high performance units, with the complete accessory kit including Cold Weather Battery Pack and cable are IN-STOCK and AVAILABLE NOW at a special sale price of $10,999!

Also available are the L3Harris M914A (AN/PVS-14) and M2124LR (CNVD-LR), also with High Performance FOM 2376+ Unfilmed White Phosphor tubes:

tnvc.com/shop/l3h-m914a-pvs14-2376fom – $4,599

tnvc.com/shop/cnvd-lr – $9,999

Also available on sale, the B. E. Meyers MAWL-C1+ (FDE & Black) – the MAWL-C1+, the Class I commercially available version of the MAWL-DA offers superior IR illumination with one of the cleanest and clearest beam patterns and exceptional long-range performance. The MAWL-C1+ bucks the common “laser box” paradigm of most Multi-Function Aiming Lasers (MFAL), allowing it to offer unparalleled ergonomics and switch easily from mode to mode as the situation dictates. These new-production units feature the latest beam divergence patterns and “Triple-Click” functionality to provide one of the most versatile and capable Class I MFALs on the market.

tnvc.com/shop/b-e-meyers-mawl-c1-ir-visible-laser – Use Coupon Code: THISLITTLELIGHTOFMINE

We are also offering 20% OFF select IN-STOCK Ops-Core FAST ballistic helmets, including the FAST SF Ballistic – including TNVC’s Exclusive M81 Woodland FAST SF0, Legacy FAST XP, and FAST Sentry, as well as all IN-STOCK AMP Headsets and Helmet Mount Rail Arms!

tnvc.com/shop/category/brands/ops-core – Use Coupon Code: TNVCVETSDAY22

Finally, we are offering the small but might TNVC/Steiner TOR-MINI IR Variable Power Control (v)2 for $229.49 each!

tnvc.com/shop/steiner-tnvc-tor-mini-ir-vpc-variable-power-control

tnvc.com/shop/category/brands/tnvc/veterans-day-sale-2022

Maxim Defense unveiled their new PDX-SD to government and military customers at yesterday’s demo day portion of the Global SOF Foundation‘s Modern Warfare Week.

Chambered for 5.56 NATO, this personal defense weapon was designed around the suppressor which is hearing safe while firing M855, demonstrating 138 dB in testing.

This model features a 5.5” barrel and 23.75” OAL collapsed. The suppressor is 5” x 2.25”. While it’s short, they made it fat as well to create volume. It also incorporates their SCW stock to help with length.

The goal was to create weapons which are always suppressed. Consequently, the suppressor is the muzzle device. The outer tube of the suppressor comes off for maintenance. Additionally, as cores wear out, they can be replaced. Not only that, but cores can be upgraded as newer versions are created.

I had an opportunity to put a couple of magazines through the PDX-SD and while I wore hearing protection, I could tell it was definitely suppressed and I experienced no gas in my face which was very welcome.

Interestingly, they have found that the weapon is quieter shooting supersonic .300BLK ammunition than subsonic with this design.

With the launch of the PDX-SD, Maxim Defense is poised to become the first company to introduce an entire line of integrally suppressed carbines, in 5.56, .300BLK, and 7.62 x 39 with the SDX line and SD15.

The PDX-SD along with the entire line of Maxim suppressors and firearms will be available to the public for test firing at this weekend’s CANCON in Georgia.

Today we honor and celebrate the bravery, sacrifice and steadfast resolve of our veterans. We live in a unique country that is blessed with individual freedoms the rest of the world can only envy. Thank you to all that have served for protecting those freedoms. From our FirstSpear family to yours, thank you for your honorable service and to those that continue to serve, you are admired in your endeavor.

Happiest of birthdays to the United States Marine Corps. May you have many more years of service to our great nation. “Semper Fidelis.”

Here are some familiar FirstSpear faces from far off places.

We proudly employ veterans. To learn more about FirstSpear, visit first-spear.com.

Our message on this Veterans Day is pretty simple and like Remembrance Day, it goes for our brothers and sisters both here in the United States as well as our allies.

Thank you for your service, and please keep it up.

For those of us who aren’t serving, support those that do.

Everyone, have a Happy Veterans Day (yes, I said it). Enjoy the day, you earned it.

That is all…