Kardax Solutions, working in coordination with Improve Group, is pleased to announce the completion of Phase I of the ACTION (Advanced Combat Training InnovatiON) Range for the 351ST Special Warfare Training Squadron at Kirtland AFB in New Mexico. The success of Phase I is notable in several ways, and we look forward to the next phases of the program. The focus for this innovative range is to improve the lethality, survivability, and combat readiness of the PJ and CRO students. The specific goals of Phase I were:

• Improve the efficiency of the overall training program

• Improve the effectiveness and realism of the training program

• Provide meaningful, repeatable metrics to enable evaluation of training methods and increased capabilities of students.

Each of these goals were addressed using various methods to provide a significant upgrade to the total training capability of the range. Because of the flexibility of the design of the facility, usage can be easily adapted to the requirements of other US Air Force combat teams, other special warfare personnel, and other branches of the DoDs training requirements. The modular design will allow the foundation technology to be scaled to larger or smaller footprints and other locations.

The first of the three-phase program for the 351st SWTS provided two innovative ranges:

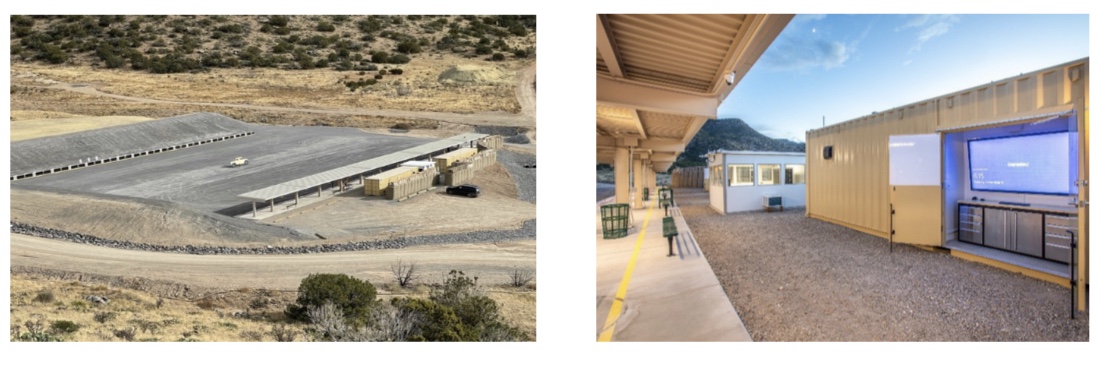

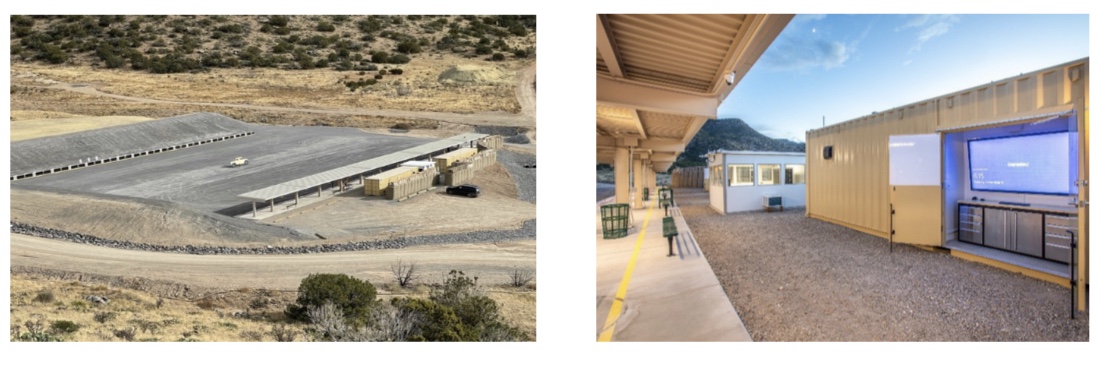

The first range is a 37-lane, 50m flat shooting range for qualification, marksmanship and fundamental movement and tactics with automated, hit sensing, auto-scoring targets. The auto-scoring targets have three distinct zones that provide real-time results for each student. Each lane also has an integrated live camera feed that makes zeroing rifles more efficient. The camera system allows a “pinch-to-zoom” interface to show hit location for every shot, eliminating the need to call a range cold to check shot location. The range has an integrated camera system providing multi-angle video on six lanes with recording features that broadcast to the instructional coaching booths, allowing on-site, instant instructional feedback to increase training effectiveness and skill retention. The Range Extractor Database enables the managements of students, real-time leaderboards, flexible reporting, and facilitates analysis of performance at the class or individual level. The data can also be evaluated over the length of the class training to show historical trends and improvement for individuals, teams, and the class as a whole. The 50m range is a fully illuminated range with low level lighting for the targets as well.

The second range is a Shoot-Move-Communicate (SMC) range that consists of three separate lanes of action including 30 targets, each with progressively more challenging terrain for long range skill building, combat marksmanship and advance/retreat tactical movements for small teams. This is the first live-fire SMC range approved and owned by the US Air Force. This training facility significantly increases the real-world scenario simulation for students, increasing student competency for fire and movement training. All firing positions teach students use of cover and concealment and all targets in the system are programmable, hit sensing, and controllable from the RSO Tower.

During the initial phase of the program, Kardax Solutions also provided the MVP HEKTR (Humanoid Engageable Kinetic Training Robot). HEKTR is a remote control, fully armored, all-terrain, responsive, live-fire target that emulates the realism of a moving threat. HEKTR brings an entirely new level of dynamic engagement to the range with humanoid movement, multiple target zones, geofencing, motion restraints and fully programmable features in terms of time, hits, and responses. The HEKTR provides enhanced training scenarios to both ranges to develop the combat mindset of students.

The metrics from this complex training environment will not only drive improvements in weapons training methodologies and student performance but also provide a foundation for mapping Human Performance data and enhancing sound tactical decision-making processes.

Phase II and III of the range hold tremendous potential for further expansion and advancement of training capabilities with ranges such as a live-fire vehicle track, high angle shooting with immediate shot detection feedback and disabled vehicle rescue. In additional, the infrastructure is now in place to expand realistic training scenario ranges.

For further information regarding the prototype range and for additional contracting opportunities using the OTA contract, please contact Lance McGlocklin at Kardax Solutions (lance@kardaxsolutions.com).