Carinthia’s new G-LOFT Tactical Poncho is Reversible from original MultiCam to olive green. Like the name says, this multifunctional poncho features 60g G-LOFT insulation.

www.carinthia.eu/en/g-loft-tactical-poncho-multicam-p3096

Carinthia’s new G-LOFT Tactical Poncho is Reversible from original MultiCam to olive green. Like the name says, this multifunctional poncho features 60g G-LOFT insulation.

www.carinthia.eu/en/g-loft-tactical-poncho-multicam-p3096

ANOKA, Minnesota – September 16, 2021 – Federal Ammunition is proud to announce a partnership with nutrition brand Go Condition to offer an exciting new line of energy bars and supplements to help hunters and shooters get more from their sport. Federal enlisted the expert sports nutrition team at Go Condition to create a targeted range of sports-specific, nourishing products that help shooters in the field.

“We partnered with the team at Go Condition to come up with a great new line of nutritional products for hunters and shooters. They are experts in what they do, and they closely worked with us to match the right product to our pursuits,” said Federal’s Vice President of Marketing Jason Nash. “Primed is formulated with the same dedication to quality, accuracy and effectiveness that we apply to the development of all of our products. As active participants in shooting sports ourselves, we know how important it is to stay awake, energetic, focused and alert when it comes time to make the shot.”

“The Federal team approached us to create a range of supplements and bars that delivered on the unmet needs of hunters and shooters both in the field and on the range,” said Go Condition’s Vice President and General Manager Andrew Heddle. “Federal has exacting standards for everything they do, and this extends to these nutrition products as well. These new products deliver a balance of effectiveness, energy and alertness when the outdoorsman needs them, without over stimulating them or causing an energy crash. Together, we created a range of products with easy to understand ingredients in quantities that make a difference without artificial and unnecessary stimulants to get in the way of the perfect shot.”

Go Condition is a sports nutrition product developer specializing in creating nutritional products for people who live, work and play hard in the outdoors. They create products for diverse brands addressing sports specific needs in the hunting, shooting, biking, hiking and golf segments, as well as marketing a range of products under their own brand which can be found at www.gocondition.com.

Primed Nutrition products are available at the company’s website and at retail partners nationwide. To learn more about this new product line, visit www.primednutrition.com.

Federal Ammunition can be found at dealers nationwide or purchased online direct from Federal. For more information on all products from Federal or to shop online, visit www.federalpremium.com.

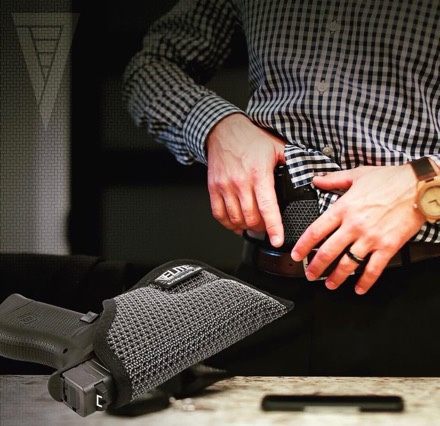

Featuring a silicone-coated outer shell for slip resistance, the Mainstay is available for a wide variety of pistols. It’s also Made in the USA.

elitesurvival.com/collections/concealed-carry-holster/products/mainstaya-clipless-iwb-pocket-holster

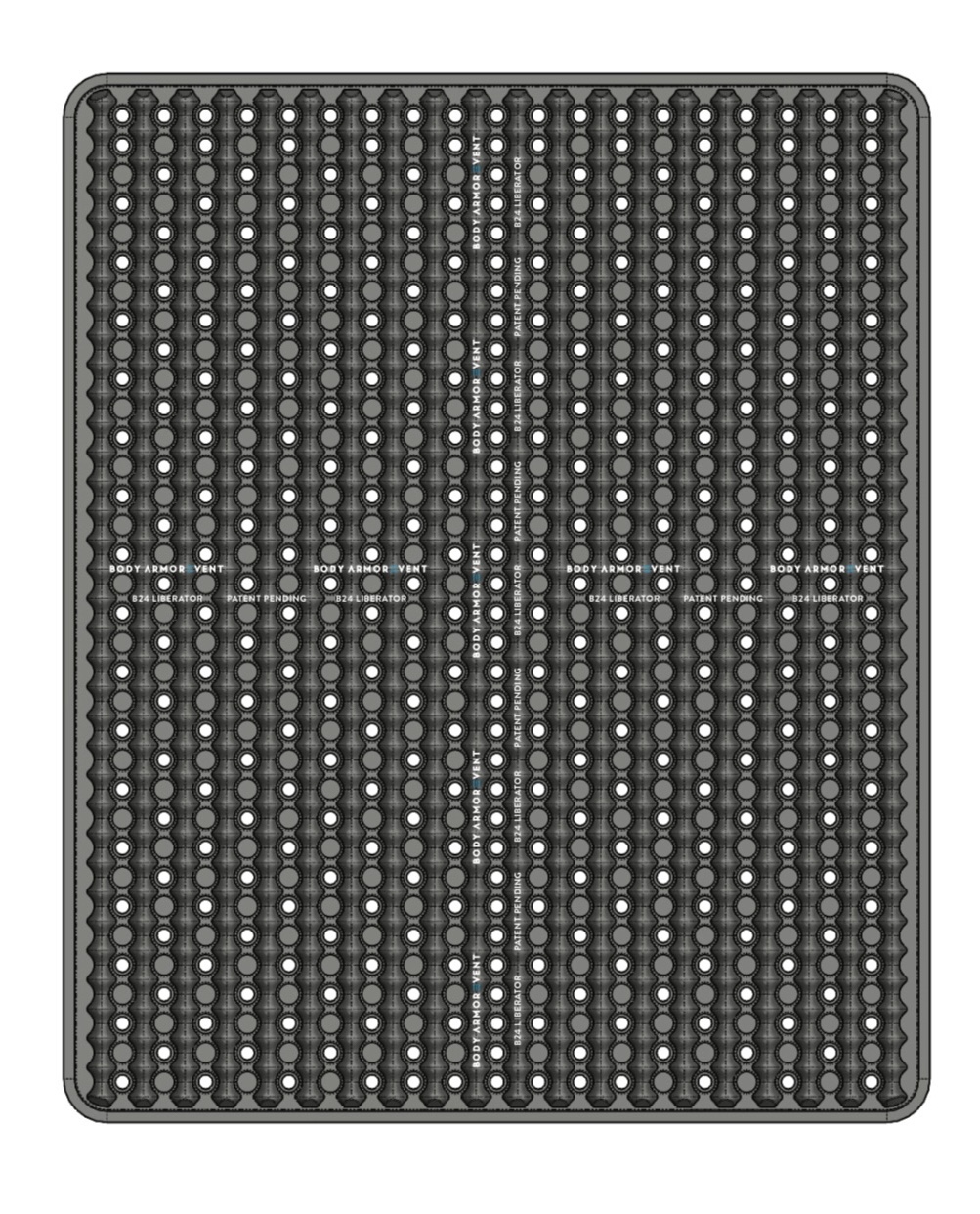

Body Armor Vent is introducing the B24 Liberator in December. It’s a 500 cm x 600 cm vented panel backed by loop fabric which can be cut by either laser or scissors, allowing it to be customized for wear behind cummerbunds, under shoulder straps, behind SAPI plates, munitions & radio carriers, holsters and other items.

SOFWERX, in collaboration with USSOCOM PEO SOF Warrior (PEO-SW), will host an Assessment Event (AE) 02-03 November 2021 to identify solutions for the Maritime Assault Suit System (MASS) and Lightweight MASS (L-MASS). These suits would be used as a combat/dry suit for the Naval Special Warfare community in maritime, land, airborne, shipboard, and transitional environments.

This program is seeking the following surface dry suit variants: (1) Maritime Assault Suit System (MASS) and (2) Lightweight MASS (L-MASS). These suits would be used as a combat/dry suit for the Naval Special Warfare community in maritime, land, airborne, shipboard, and transitional environments. The MASS and L-MASS must be comfortable, yet durable enough for rugged field use. Weight of MASS not to exceed 5-lbs and L-MASS not to exceed 4-lbs. They must keep the Operator as dry as possible in maritime and all weather conditions, including surface swims and while immersed in 10 feet of water for 1 minute. They should not restrict range of motion for activities including, but not limited to swimming, running, assault movements, and weapons manipulation.

View the Statement of Objectives (SOO) here.

Submit NLT 11 October 11:59 PM ET

Visit events.sofwerx.org/mass for details.

Limassol, Cyprus – As part of a bi-lateral training exercise in Cyprus the Cypriot Underwater Demolition Team (MYK) is hosting U.S. Naval Special Warfare Task Unit Europe (NSWTU-E) beginning 07 September 2021. This is one of a series of training events throughout the Eastern Mediterranean directed at building cohesion between NATO allies and partners while increasing readiness in the face of multiple threats to the peace and stability of Europe.

“You can see the very real demonstration of cohesion we build during exercises like this with partners like Cyprus,” said the Naval Special Warfare Officer-in-Charge. “We simply cannot accomplish the mission alone – by exchanging tactics and ideas, we build cohesion necessary to defeat any challenge.”

NSWTU-E is currently training with members of the MYK on maritime operations. Joint training in the eastern Mediterranean is essential in maintaining interoperability and strong relationships with our ally and partner nations, ensuring stability throughout the theater.

Story by Capt Margaret Collins DuTart, U.S. Special Operations Command Europe

Photos by Sgt Patrik Orcutt, U.S. Special Operations Command Europe

You may have run across AMNB on Instagram or the Web where he reviews a wide variety of kit, primarily for the Mil-Sim community. We’ve hit the point where the quality of products designed for Mil-Sim are getting up there. I’m not saying for professional users to go this route, but it may have utility for some readers.

CR-TAC from codeRED Headsets is a noise cancelling Dual Muff headset with “hear through” technology using electronic amplification of ambient sounds.

Overall, his impression is very positive, but Chris goes into some detail, which makes it worth your time to go read what he’s got to say.

For the whole review at airsoft-milsim-news.com/codered-cr-tac-headset-amnb-review.